Ukuhlolwa okuvamile kweizingxenye ze-crusher, kuhlanganiseizingxenye zomhlathi we-crusherfuthiizingxenye ezisele ze-cone crusher, dlala indima ebalulekile ekuqinisekiseni ukusebenza kahle nokwethembeka. Ucwaningo lubonisa lokhoukulungiswa okwanele kwemishininjengei-crusher ye-gyratorykungaholela ekuhlulekeni ngaphambi kwesikhathi, ngephesenti elibalulekile lezinkinga ezilandelelwa emuva ekuntulekeni kokuhlolwa.Izingxenye ezibalulekile okufanele zihlolwe zibandakanya amayunithi wamandla asebenza ngogesi, amazinga okushisa kawoyela, nezimo ezithwalayo. Ukuqapha lezi zakhi njalo akuvimbeli nje kuphela isikhathi esibizayo kodwa futhi kuthuthukisa ukusebenza kahle kwemishini yonke. Ngokwesibonelo,ukushintshwa kwe-liner ngesikhathikuma-crushers angavimbela ukulahlekelwa kokusebenza, ekugcineni andise impilo yesevisi yezingxenye ezibucayi, ikakhulukazi lezo ezenziwe ngazohigh manganese steel cast.

Okuthathwayo Okubalulekile

- Ukuhlolwa okujwayelekile kwezingxenye ze-crusher kubalulekile ekusebenzeni kahle nokuphepha. Gxila ezingxenyeni ezigugile, izindawo zokugcoba, ukuqondanisa, izingxenye zikagesi, kanyeubuqotho besakhiwo.

- Sebenzisa uhlelo lokulungisa oluqinile. Yenza ukuhlolwa kwansuku zonke ukuze uthole amabhawodi axegayo kanye nokugcoba, ukuhlola okubonakalayo kwamasonto onke, nokuhlola kwanyanga zonke kwesistimu yomshini.

- Qaphela izimpawu zokuguga, njengokudlidliza ngokweqile, umsindo, nemifantu ebonakalayo. Ukutholwa kusenesikhathi kuvimbela ukwehluleka okungalindelekile kanye nesikhathi sokuphumula esibizayo.

- Sebenzisaizinto ezisezingeni eliphezulu zezingxenye zokugqokaukuthuthukisa ukuqina. Ukuhlola okuvamile kusiza ukukhomba lapho kudingekile ukushintshwa, kunwebe impilo yesevisi yezingxenye ezibalulekile.

- Beka kuqala ukuphepha kukagesi ngesikhathi sokuhlolwa. Hlola ukuxhumeka ukuze uthole ukuvikeleka futhi uqinisekise ukuthi izintambo ezingaphansi ziqinile ukuvimbela izingozi zomlilo futhi uqinisekise ukusebenza okuphephile.

Gqoka Izingxenye

Izingxenye zokugqoka ziyizingxenye ezibalulekilekunoma iyiphi i-crusher. Babhekana nokuguga okukhulu ngesikhathi sokusebenza. Ukuhlolwa okuvamile kwalezi zingxenye kusiza ukugcina ukusebenza kahle futhi kuvimbele ukwehluleka okungalindelekile. Izingxenye zokugqoka eziyinhloko zihlanganisaipuleti lomhlathi eligxilile, ipuleti lomhlathi elinyakazayo, namapuleti ezihlathini. Ngayinye yalezi zingxenye idlala indima ebalulekile enqubweni yokuchotshozwa.

Nasi isifinyezo sezinhlobo eziyinhloko zezingxenye zokugqoka ezitholakala kuma-crusher:

| Uhlobo Lwengxenye Yokugqoka | Incazelo |

|---|---|

| Izingxenye zokugqoka ze-jaw crusher | Kuhlanganisa i-jaw plate engashintshi, i-jaw plate ephathekayo, namapuleti ezihlathini. |

| Ipuleti lomhlathi elingashintshi | Ukufakwa emzimbeni we-crusher yomhlathi; itholakala ngemiklamo eyisiqephu esisodwa nambili. |

| Ipuleti lomhlathi elinyakazayo | Ukufakwa emihlathini ehambayo; iyatholakala futhi ngemiklamo eyisiqephu esisodwa nambili. |

| Amapuleti ezihlathini | Ivikela uhlangothi lomzimba we-gaw crusher emonakalweni wetshe elichotshoziwe. |

Ukuhlolwa okuvamile kwezingxenye ze-jaw crusherkufanele kwenzeke njalo ngamahora okusebenza angama-250. Ukulandela ishejuli yokunakekela eqinile nokuhlolwa kwansuku zonke, kweviki, kanye nenyanga kubalulekile. Ama-opharetha kufanele abhekeizimpawu zokuguga ngokweqile, njenge:

- Ukudlidliza okwedlulele noma umsindo

- Imifantu ebonakalayo noma ukulimala kwesakhiwo

- Ukunciphisa amapuleti okugqoka nama-liner

- Amaphethini okugqoka angalingani

- Ukukhiqiza okuncishisiwe noma umkhiqizo omkhulu kakhulu

- Ukuvinjelwa njalo noma ukuminyana kwempahla

- Ukwenyuka kokusetshenziswa kwamandla

- Ukubhekana nezinkinga zokushisa ngokweqile noma zokugcoba

Ukuphila kwezingxenye ze-manganese kungahluka kakhulu, kusukelaamasonto ayisithupha kuya eminyakeni eyisithupha, kuye ngokuthi idwala licutshungulwa. Ukukhethaizinto ezisezingeni eliphezulukubalulekile ukuze izingxenye ezigugile zibekezelele izimo ezinzima. Izinto ezisetshenziswayo ze-Premium zithuthukisa ukumelana nemihuzuko, umthelela, nokuguga, okuholela empilweni ende yesevisi. Ukuhlola okuvamile kusiza ukuhlonza amaphethini okuguga nokunquma lapho kudingekile ukushintshwa.

Ukusebenzisaukukhethwa kwekhwalithi nokuhlolwa okuvamilekwandisa ukusebenza nokuqina. Ukunakekelwa okufanele kanye nokusebenza okulungiselelwe kubalulekile ukuze kungabizi kangako. Ukuqeqeshwa kwama-opharetha nakho kunomthelela ekusebenzeni kahle okuphelele kwezingxenye ezigqokile.

Amaphuzu Okugcoba

Ukugcoba ngendlela efanele kubalulekile ekusebenzeni kahle kwezingxenye ze-crusher. Ukuhlola njalo izindawo zokuthambisa kuvimbela ukwehluleka kwemishini futhi kwandise isikhathi sokuphila sezingxenye ezibalulekile. Iphuzu ngalinye lokuthambisa linezidingo ezithile okufanele abaqhubi bazilandele ukuze bagcine ukusebenza kahle.

Nawa amanye amaphuzu abalulekile wokugcoba kanye nawookokugcoba okunconyiwe:

| Iphoyinti Lokugcoba | I-Lubricant Enconyiwe | Amanothi |

|---|---|---|

| I-Eccentric Shaft Bearings | I-Jet-Lube Jet-Plex EP™ Grease | Idinga ugrisi ozinzile ukuze ulayishe ukushaqeka nokudlidliza. |

| I-Pitman Bearings | I-Jet-Lube Jet-Plex EP™ Grease | Ilayishwe kakhulu; amafutha kufanele alondoloze ukungaguquguquki. |

| I-Dynamic Suspension Shaft | Amafutha aphakathi | Igcotshwe ngaphandle kokubuya kwamafutha; idinga isicelo esijwayelekile. |

| I-Trust Plate Elbow | Amafutha awugqinsi | Idinga ukugcoba njalo ngamahora angu-3-4; ehluke kwamanye amaphuzu. |

| Ukuzala Kwemihlathi Encane | Inkomishi yamafutha namafutha okugcoba | Ingasetshenziswa kanye njalo ngemizuzu engama-30-40. |

Ama-opharetha kufanele ahleleisevisi yansuku zonke kanye nokugcoba. Kufanele bahlole imininingwane yomkhiqizi ngocezu ngalunye lwesisetshenziswa. Ukusebenzisa izinqubo zokulawula ukungcola nakho kubalulekile. Ukudebeselela lokhu kuhlola kungaholelaimiphumela emibi. Ngokwesibonelo,ukwehluleka ukuzala ngaphambi kwesikhathikungenzeka ngenxa yokungagcolisi ngokwanele. Ukwengeza, izingqinamba ezinjengama- knock-off breather zingavumela uthuli ungene egumbini likawoyela, okuholela kwezinye izinkinga.

Ukusebenzisa uhlobo olufanele lokuthambisa kubalulekile. Abaqhubi kufanele bacabangele izimo zemvelo ezifana nomswakama kanye nezinga lokushisa. Ukukhetha izinto zokugcoba ezinomshini wokuwasha amanzi aphansi kanye nokumelana nokugqwala okuphezulu kubalulekile ezindaweni ezimanzi. Izithambisi ze-viscosity eziphakeme zisebenza kangcono ezinsizeni ezinejubane eliphansi, ezinomthwalo omkhulu.

Ukuqondanisa Amasheke

Ukuhlola ukuqondanisa kubalulekile ukuze kugcinwe ukusebenza kahle nokuphila isikhathi eside kwezingxenye ze-crusher. Ukuqondanisa kahle kuqinisekisa ukusebenza kahle futhi kunciphisa ukuguga kwezingxenye. Ukuhlola okuvamile kungavimbela ukwehla kwezindleko futhi kuthuthukise ukusebenza okuphelele. Nakhu okunye ukuhlola kokuqondanisa okubalulekile okufanele kucatshangelwe:

- Ukuqondanisa Ibhande: Ukuqondisa kahle ibhande kubalulekile ekusebenzeni kahle. Iqinisekisa ukugeleza kwezinto ezibushelelezi futhi inciphisa isikhathi sokuphumula.

- Ukulinganisa i-Crusher: Ukugcina izinga le-crusher kubalulekile ekulandeleni ibhande elifanele. Lokhu kubaluleke kakhulu ngemva kokuhambisa imishini.

- Ukulungiswa Kwe-Idler: Uma ibhande liphuma endleleni, ukulungiswa kwamavila kuyadingeka. Ukunyakaza okuqondile kungalungisa izinkinga zokuqondanisa.

- Izandiso Zokuthatha: Ukunwetshwa okulinganayo noma ukuhoxiswa kokuthatha kubalulekile ekugcineni ukungezwani kwebhande. Lokhu kusiza ukuvimbela ukushelela nokuguga.

- Ukulungiswa Okusha Kwebhande: Amabhande amasha angase adinge ukulungiswa okuningi njengoba elula futhi ehlala endaweni.

Ukungaqondi kahle kungaholela emiphumeleni eminingi engemihle. Ithebula elingezansi lifingqa imithelela engaba khona yokungahleleki kahle ekukhiqizweni nasekuphileni isikhathi eside kwemishini:

| Umphumela | Incazelo |

|---|---|

| I-Accelerated Wear and Tear | Ukungaqondi kahle kubangela amandla angajwayelekile aholela ekwandeni kokungqubuzana nokuxhumana phakathi kwezingxenye. Lokhu kubangela ukuwohloka okusheshayo kanye nokugcinwa kaningi. |

| Ukungasebenzi Kwamandla | Imishini engahambi kahle idinga amandla engeziwe ukuze isebenze. Lokhu kuholela ezindlekweni eziphakeme zokusebenza kanye nokunciphisa ukusebenza kahle ekukhiqizweni kokukhiqiza. |

| Ubude bokuphila obuncishisiwe | Ukuchayeka njalo ekudlidlizeni okweqile kwenza kube mfishane isikhathi sokuphila semishini. Lokhu kwandisa amathuba okuphuka kanye nesikhathi sokuphumula. |

| Izingozi Zokuphepha | Amazinga aphezulu okudlidliza angaholela ekuhlulekeni okuyinhlekelele. Lokhu kudala ubungozi kubasebenzi nengqalasizinda ezungezile. |

| Izinkinga Zokulawula Ikhwalithi | Imiphumela engahambisani evela kumishini engaqondani kahle ingaholela ekulethweni okusezingeni eliphansi. Lokhu kuthinta ikhwalithi yokukhiqiza iyonke. |

Ukuze benze ukuhlola kokuqondanisa ngokuphumelelayo, opharetha bangasebenzisa amathuluzi namasu ahlukahlukene. Ithebula elilandelayo libonisa izinhlobo zezinto ezijwayelekile kanye nokubaluleka kwazo ekuhloleni ukuqondanisa:

| Uhlobo Lwezisetshenziswa | Ukubaluleka Kokuhlola Ukuqondanisa |

|---|---|

| Ama-turbines (igesi, umoya, umusi) | Ingabhekana noshintsho olukhulu lokushisa okubangela ukunyakaza kwamapayipi nezisekelo. |

| Ama-Chillers apholile | Izingxenye eziqondanisiwe zisengozini yokunyakaza okungahlosiwe ngenxa yokufakwa kwe-compressor. |

| Amanzi Apholile, Amanzi Acondenser, namaphampu Amanzi Okuphakelayo | Ukushintsha kwezinga lokushisa kungabangela ukunyakaza komshini, ikakhulukazi uma izisekelo zingezinkulu ngokwanele. |

| Extruders | Ukushintshashintsha kwezinga lokushisa okukhulu kungaholela ekuhambeni komshini ngokuhamba kwesikhathi. |

| Izigayo zeHammer, Crushers | Ubunjalo bomsebenzi bungabangela ukunyakaza okungahlosiwe, ngisho noma kufakwe ibhawudi. |

| Eminye Imishini | Inikeza izinzuzo ezinjengokuhlola ama-couplings nama-seals, nokuzilolonga ngamathuluzi okuqondanisa. |

Ukuhlolwa kokuqondanisa okuvamile kubalulekile ekugcineni ukusebenza kahle nokuphepha kwezingxenye ze-crusher. Ukusebenzisa uhlelo lokuhlola okuvamile kungathuthukisa kakhulu ukusebenza kwemishini nokuphila isikhathi eside.

Izingxenye zikagesi

Izingxenye zikagesi zidlala indima ebalulekileiqhaza ekusebenzeni kwama-crusher. Ukuhlolwa okuvamile kwalezi zingxenye kusiza ukuvimbela ukwehluleka futhi kuqinisekise ukuphepha. Abasebenzisi kufanele bagxile ezindaweni ezimbalwa ezibalulekile ngesikhathi sokuhlolwa kwabo.

Izinkinga zikagesi ezijwayelekileezitholakala ngesikhathi sokuhlolwa kwe-crusher zihlanganisa:

- Izinkinga zokuphakelwa kwamandla kagesi, njenge-voltage engazinzile noma ukungabi namandla.

- Ukushintsha kokuqala okunephutha noma izinkinga ngephaneli yokulawula.

- Ama-fuse ashaywayo noma ama-circuits breaker.

- Izikhiye zokuphepha ezivuliwe noma izitobhi eziphuthumayo.

- Izintambo ezingalungile noma ukuxhumana.

- Ukwehluleka kwezinzwa noma amaphutha okuxhumana kumasistimu azenzakalelayo.

- Amaphutha esoftware noma i-firmware ephelelwe yisikhathi.

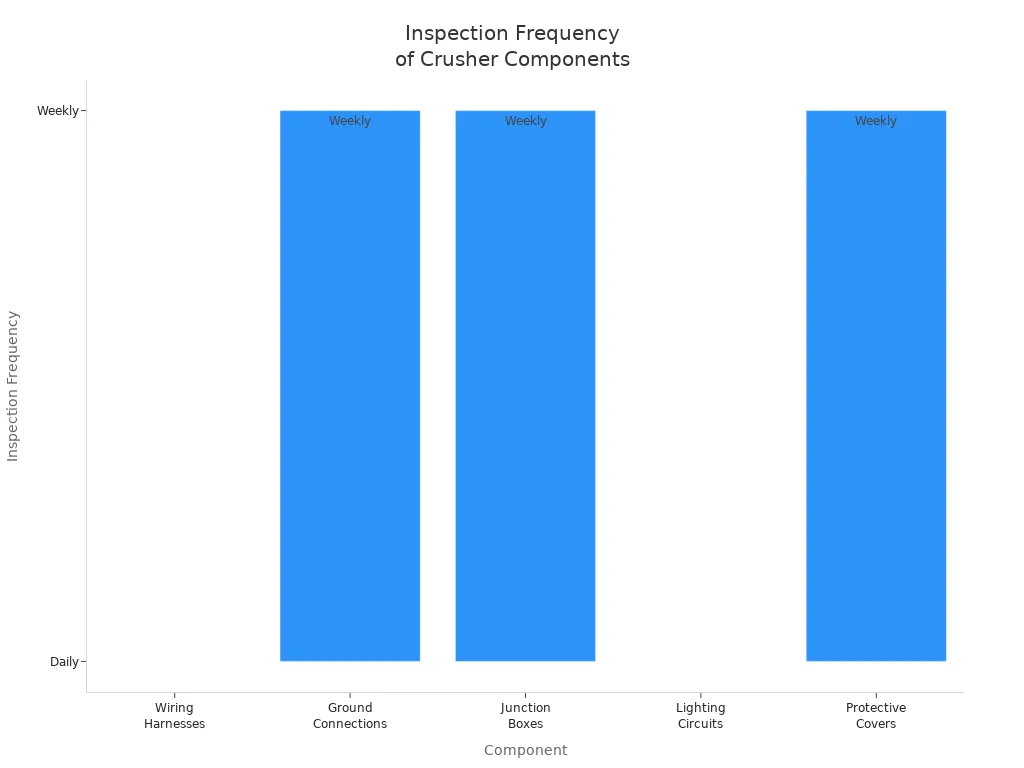

Ukuthobela imithetho yezokuphepha, abaqhubi kufanelehlola izingxenye zikagesi njalo. Ithebula elilandelayo lichaza iizinhlobo zokuhlola ezinconyiwe namafrikhwensi:

| Isakhi | Uhlobo Lokuhlola | Imvamisa |

|---|---|---|

| Izintambo zokubopha | Okubukwayo/Okomzimba | Nsuku zonke |

| Ground Connections | Isivivinyo Sokumelana | Maviki onke |

| Amabhokisi Okuhlanganisa | Ukuhlola Umswakama | Maviki onke |

| Lighting Circuits | Ukuhlola Umsebenzi | Nsuku zonke |

| Amakhava Okuzivikela | Ukuhlola Ubuqotho | Maviki onke |

Ukuhlola izintambo zikagesi nezixhumi kubalulekile. Abasebenzisi kufanele:

- Qinisekisa ukuthi ukuxhumana kukagesi kuvikelekilengaphambi kokuqala noma yimuphi umshini.

- Njalo hlola ukuxhuma okuxekethile noma izintambo eziphukileukugwema izingozi zomlilo.

- Qinisekisa ukuthi izintambo eziphansi, amapulaki ezimoto, noxhumo lwekhebula lamandla kuvikelekile ngaphambi kokusebenza kwezinto zokusebenza.

Ukudebeselela lokhu kuhlola kungaholela ezingozini ezinkulu.Impahla kagesi engalungile ingabangela imililo, okwenza kube semqoka ukuba namandla okucisha umlilo esizeni. Ukuhlola okubonakalayo okuvamile kusiza ukuqinisekisa ukuphepha nokusekelwa okufanele kwekhebula. Ukwengeza, amakamelo okufaka ugesi kufanele ahlale omile futhi engenazo izinto ezivuthayo.

Ngokubeka kuqala ukuhlolwa kwengxenye kagesi, opharetha bangathuthukisa ukuphepha nokusebenza kahle kwemisebenzi yabo ye-crusher.

Ubuqotho Besakhiwo

Ukugcina i-ubuqotho besakhiwo se-crusheribalulekile ekusebenzeni okuphephile nokusebenza kahle. Ukuhlola okuvamile kusiza ukuhlonza izinkinga ezingase zibe khona ngaphambi kokuba zidlulele ekuhlulekeni okuyinhlekelele. Abasebenzisi kufanele bagxile ekuhloleni okubalulekile okuningana ukuze baqinisekise ukuzwakala kwesakhiwo semishini yabo.

Naziamasheke obuqotho besakhiwo kuma-crusher:

| Hlola Uhlobo | Incazelo |

|---|---|

| Amasheke we-Bolt Torque | Amashejuli ejwayelo okuhlola kanye nokushintshanisa kabusha amabhawodi esakhiwo abalulekile abalulekile. |

| Ukuhlolwa Kwe-Crack | Ukuhlolwa ngezikhathi ezithile kokuqhekeka kwezinwele, ikakhulukazi ezindaweni zokugxilisa ingcindezi, kubalulekile. |

| Ukuthambisa | Ukugcoba ngendlela efanele ngohlobo olufanele kanye nebanga kuvimbela ukushisa nokuguga. |

| Ukuhlaziya Ukudlidliza | Ukuhlola okuvamile kungathola izimpawu zokuqala zokwehluleka ngaphambi kokuba kuholele ekulimaleni okuyinhlekelele. |

Izici zemvelo ezifana nokudlidliza nezinga lokushisa zingathinta kakhulu ubuqotho besakhiwo sezingxenye ze-crusher.Ukwehluka kwezinga lokushisa nemithwalo yangaphandlelukhuni ukuguquguquka kwesakhiwo, okungaholela ekuhlulekeni. Isibonelo, ukusebenza ngesivinini esiphezulu kungabangela ukudlidliza okukhulu, okuholela ekulimaleni kwesakhiwo. Ukuthambisa okufanele kubalulekile ukuze unciphise lezi zingozi.

Izinkinga zesakhiwo ezijwayelekile ezikhonjwe ngesikhathi sokuhlolwazihlanganisa:

- Ukuhluleka Kwemishini

- Ama-Bearings ashisa ngokweqile noma aguga ngaphambi kwesikhathi.

- Ukuqhekeka noma ukuphuka kuhlaka lwe-crusher.

- Ukudlidliza kanye Nomsindo

- Ukudlidliza okwedlulele noma umsindo ngesikhathi sokusebenza.

- Ukwehluleka Kwesistimu Ye-Hydraulic

- Ukuvuza noma ingcindezi enganele.

Ukuhlolwa okuvamile nokugcinwa kobuqotho besakhiwo kungavimbela isikhathi sokuphumula esibizayo futhi kuthuthukise impilo yezingxenye ze-crusher. Abasebenzisi kufanele babeke phambili lokhu kuhlola ukuze baqinisekise ukusebenza okuphephile nokusebenza kahle.

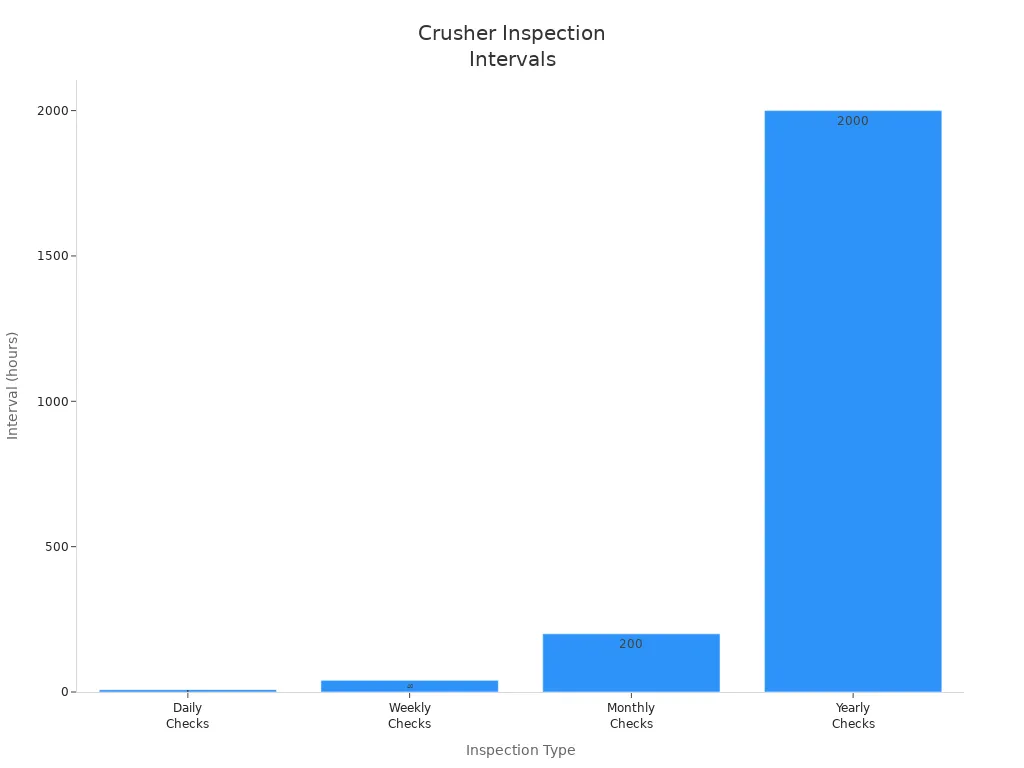

Ukuhlolwa okuvamile kwezingxenye ze-crusher kubalulekile ukuze kugcinwe ukusebenza kahle nokuphepha. Izindawo zokuhlola ezibalulekile zihlanganisa:

- Ukuhlolwa Kwansuku Zonke: Hlola amabhawodi axegayo, hlola amapuleti emihlathi, bese ugcoba izingxenye ezihambayo.

- Isondlo Samasonto onke: Yenza ukuhlolwa okubonakalayo futhi uhlole ama-wear liners.

- Isondlo Sanyanga Zonke: Hlola amasistimu emishini namazinga kawoyela.

- Ukulungiswa kabusha konyaka: Hlukanisa futhi uhlole izingxenye ezigqokile ukuze uthole umonakalo.

Ukusebenzisa uhlelo lokuhlola okuvamile kunciphisa kakhulu isikhathi sokuphumula kanye nezindleko zokulungisa. Ukunganaki isondlo kungaholelaukwephulwa ngokweqile, kubiza cishe u-$50,000 ngehora. Ngokubeka kuqala ukuhlolwa okuvamile, opharetha bangathuthukisa isikhathi eside semishini nokusebenza kahle.

FAQ

Yiziphi izingxenye ezibaluleke kakhulu okufanele uzihlole ku-crusher?

Ama-opharetha kufanele njalohlola izingxenye zokugqoka, izindawo zokuthambisa, ukuqondanisa, izingxenye zikagesi, nobuqotho besakhiwo. Lezi zindawo zithinta kakhulu ukusebenza kwe-crusher nokuphila isikhathi eside.

Kufanele ngihlole kangaki ku-crusher yami?

Ukuhlolwa kwansuku zonke kubalulekile kumabhawodi axegayo kanye nokugcoba. Ukuhlola kwamasonto onke kufanele kufake phakathi ukuhlola okubonakalayo, kuyilapho ukunakekelwa kwanyanga zonke kugxile ezinhlelweni zemishini. Ukulungiswa kabusha kwaminyaka yonke kubalulekile ukuze kuhlolwe kahle.

Yiziphi izimpawu ezibonisa ukugqokwa kwezingxenye ze-crusher?

Izimpawu zokugqoka zihlanganisa ukudlidliza ngokweqile, umsindo, imifantu ebonakalayo, amapuleti okugqoka amancane, namaphethini okugqoka angalingani. Abasebenzisi kufanele baqaphe lezi zinkomba ukuze bagweme ukwehluleka okungalindelekile.

Kungani kubalulekile ukuthambisa okufanele kuma-crushers?

Lubrication efanelekunciphisa ukungqubuzana nokuguga ezingxenyeni ezihambayo. Ivimbela ukushisa ngokweqile futhi inwebe isikhathi sokuphila sezingxenye ezibalulekile, iqinisekisa ukusebenza kahle nokunciphisa isikhathi sokuphumula.

Ngingakuqinisekisa kanjani ukuphepha kukagesi ngesikhathi sokuhlolwa?

Hlola ukuxhunywa kukagesi ukuze uthole ukuphepha futhi uhlole izintambo eziphukile. Qinisekisa ukuthi izintambo eziphansi kanye noxhumo lwekhebula lamandla luqinile. Ukuhlola okubonakalayo okuvamile kusiza ukugcina ukuphepha nokuvimbela izingozi zomlilo.

Isikhathi sokuthumela: Oct-17-2025