Insimbi ye-manganese ephezuluigqame ngenxa yokumelana nokugqokwa kwayo okungenakuqhathaniswa nokuqina, okuyenza ibe yingxenye ebalulekile ku-Izingxenye Zomshini Wokugaya. Lezi zinto zingabekezelela izimo ezimbi kakhulu, ezithuthukisa ukusebenza kahle emkhakheni wezimayini. Ngokuphawulekayo, izinkampani zonga kakhulu ngensimbi ephezulu ye-manganese, ikakhulukazi uma zisebenzisaI-Manganese Steel Hammeremisebenzini yabo. Ngokwesibonelo, bangazuza ukonga ngonyaka$3.2 millionkuzo zonke izigaba zezindleko ezahlukahlukene. Lokhu kufaka phakathi izigidi ezingu-1.95 zamaRandi ezongiwe ekunciphiseni isikhathi sokungasebenzi esingahlelelwe, ukuthuthukisa ukutholakala kwemishini kusuka ku-76.5% kuya ku-91.2%. Ukwengeza, izindleko zokulungisa izimo eziphuthumayo zehla ngo-$680,000 minyaka yonke ngenxa yokutholwa kwenkinga kusenesikhathi nokulungiswa okuhleliwe, ikakhulukazi lapho kuqashwa.I-Manganese Wear Plateukuqina okwengeziwe. Ngaphezu kwalokho, ngempumeleloUkwenza insimbi yeManganeseivumela ukwakhiwa okunembayo kwezingxenye, kuqhubeke kuthuthukise ukusebenza nokuhlala isikhathi eside kwemishini ezindaweni ezidinga kakhulu.

Okuthathwayo Okubalulekile

- Insimbi ye-manganese ephezuluinikeza ukumelana nokugqokwa okungenakuqhathaniswa nokuqina, okwenza kubaluleke kakhulu emishinini yezimayini.

- Ukusebenzisa insimbi ephezulu ye-manganese kungasindisa izinkampani kuze kufike ku-$3.2 million ngonyaka ngokunciphisa isikhathi sokuphumula kanye nezindleko zokulungisa.

- Amandla okuqinisa umsebenzi wensimbi ephezulu ye-manganese akhuphula ubulukhuni bayo ngaphansi komthelela, akhulise ukuqina kwayo ezimeni ezinzima.

- Izingxenye zensimbi ye-manganese ephezulu zingahlala isikhathi eside kakhulu kunezinye izindlela, okuholela ekwehliseni izindleko zokulungisa nokushintshwa.

- Ukutshala imali ensimbi ephezulu ye-manganese kuthuthukisa ukusebenza kahle,ukunciphisa isikhathi sokuphumulakuze kufike ku-30% futhi kukhuliswe ukukhiqiza.

Izakhiwo Ezihlukile Zensimbi Ephakeme YeManganese

Ukuqanjwa Nesakhiwo

Insimbi ye-manganese ephezulu, evame ukubizwa ngokuthi i-Hadfield steel, iqukethe inhlanganisela eyingqayizivele yezinto ezifaka isandla ezintweni zayo ezingavamile. Ukwakheka kwamakhemikhali okujwayelekile kwensimbi ephezulu ye-manganese esetshenziswa ekuchotsheni izimayini kuhlanganisa:

| Ibanga | C (%) | Mn (%) | P (%) | S (%) | Cr (%) | I-Ni (%) |

|---|---|---|---|---|---|---|

| I-GX120Mn13 | 1.05-1.15 | 11-14 | Ubukhulu. 0.06 | Ubukhulu. 0.045 | - | - |

| I-GX120MnCr13-2 | 1.05-1.35 | 11-14 | Ubukhulu. 0.06 | Ubukhulu. 0.045 | 1.5-2.5 | - |

| I-GX120Mn18 | 1.05-1.35 | 16-19 | Ubukhulu. 0.06 | Ubukhulu. 0.045 | - | - |

| I-GX120MnCr18-2 | 1.05-1.35 | 16-19 | Ubukhulu. 0.06 | Ubukhulu. 0.045 | 1.5-2.5 | - |

| I-GX120MnNi13-3 | 1.05-1.35 | 11-14 | Ubukhulu. 0.06 | Ubukhulu. 0.045 | - | 3-4 |

| I-GX120MnMo13-2 | 1.05-1.35 | 11-14 | Ubukhulu. 0.06 | Ubukhulu. 0.045 | - | 1.8-2.1 |

Izingxenye eziyinhloko zensimbi ephezulu ye-manganese zifaka i-manganese, i-carbon, nensimbi.Okuqukethwe kweManganese kuvamise ukuhluka kusuka ku-11% kuya ku-14%, kuyilapho ikhabhoni ihluka ngokwezinga. Lokhu kwakheka okukhethekile kuholela ku-microstructure ethuthukisa ukumelana nokugqoka kanye nokuqina.

I-microstructure yensimbi ephezulu ye-manganese idlala indima ebalulekile ekusebenzeni kwayo. Ifaka isakhiwo esihlukile esine-pearlite ecolisekile kanye nama-carbides. Leli lungiselelokwandisa ukumelana nemihuzuko cishe ngo-16.4%. Izinto ezisetshenziswayo futhi zibonisa ukuqina okuphezulu kanye ne-ductility, okuyenza ifaneleke izinhlelo zokusebenza ezidinga ukumelana nomthelela kanye nokuguga.

Izici Zokuqinisa Umsebenzi

Esinye sezici ezivelele zensimbi ephezulu ye-manganese iyamangalisaukusebenza kanzima ikhono. Uma ingaphansi komthelela, okokusebenza kuba noguquko okwandisa kakhulu ubulukhuni bayo. Lesi senzakalo senzeka ngenxa yokwakheka kwe-ε-martensite namawele emishini ngaphakathi kwe-matrix yensimbi.

Ithebula elilandelayo libonisa ukwanda kokuqina okubonwa emabangeni ahlukene ensimbi ephezulu ye-manganese ngaphansi kwezimo zomthelela:

| Okubalulekile | Ukuqina kwe-Matrix (HV) | Ukuqina Kwendawo Engaphansi Okugugile (HV) | Ukukhula Kokuqina (HV) | Indlela Yokuqinisa |

|---|---|---|---|---|

| Mn13 | 240.2 | 670.1 | 429.9 | Ukwakhiwa kwe-ε-martensite kanye namawele emishini |

| Mn13-2 | 256.6 | 638.2 | 381.6 | Ukwakhiwa kwe-ε-martensite kanye namawele emishini |

| Mn18-2 | 266.5 | 713.1 | 446.6 | Ukwakhiwa kwe-ε-martensite kanye namawele emishini |

Lesi sici sokuqina komsebenzi sivumela insimbi ephezulu ye-manganese ukuthi imunce amandla abalulekile ngesikhathi sokusebenza. Ngenxa yalokho, ingakwazi ukumelana nemithwalo ephezulu yethonya ngaphandle kokuphuka. Lesi sakhiwo sikwenza kube yigugu ngokukhethekile ekusetshenzisweni kwezimayini, lapho imishini ibhekene nezimo ezimbi kakhulu.

Uma kuqhathaniswa nezinye izinto ezisetshenziswa kakhulu zezimayini, insimbi ephezulu ye-manganese ibonisa amakhono aphakeme okuqinisa umsebenzi. Nakuba ingase ibonise amandla esivuno esiphansi ngaphansi kokulayisha okumaphakathi noma komthelela ophansi, ukusebenza kwayo ngaphansi kwezimo zomthelela omkhulu akufani. Le nhlanganisela eyingqayizivele yezakhiwo iqinisekisa ukuthi insimbi ephezulu ye-manganese ihlala iyinketho ekhethwayo embonini yezimayini.

Izinzuzo Zensimbi YeManganese Ephakeme Ngaphezu Kwezinto Ezihlukile

Insimbi ephezulu ye-manganese inikeza izinzuzo ezinkulu kunezinye izinto ezisetshenziswayo ekugayweni kwezimayini. Izakhiwo zayo eziyingqayizivele zinomthelelaukuqina okuthuthukisiwekanye nokuphumelela kwezindleko, okwenza kube ukukhetha okuthandwayo emisebenzini eminingi yezimayini.

Ukuqina Nokuphila Isikhathi Eside

Ukuqina kuyisici esibalulekile emishinini yezimayini. Izingxenye zensimbi ye-manganese ephezulu ngokuvamile zibonisa aimpilo ende yesevisikunezinye izinto, ikakhulukazi ngaphansi kwezimo ezijwayelekile zokusebenza. Isibonelo, amabanga aphezulu ensimbi ye-manganese, njenge-Mn22, abonisa ukuguga okukhethekile kanye nokumelana nomthelela. Lawa liner angahlala phakathiAmahora angama-250 kuye kwangama-500ezimweni eziqhumayo, insimbi evamile ye-manganese idlula kakhulu.

Uma kuqhathaniswa, izingxenye zensimbi ye-alloy zingahlala ngaphezuizikhathi ezintathu ubudekunensimbi ephezulu ye-manganese ngaphansi kwezimo zokusebenza ezifanayo. Ukuhlolwa kwaselabhorethri kuqinisekisa ukuthi amapuleti emihlathi yensimbi ye-alloy amelana nokuguga kangcono, ikakhulukazi ezindaweni eziqhumayo. Ithebula elilandelayo lifingqa izici zokuqina zensimbi ye-manganese ephezulu uma iqhathaniswa nensimbi eyingxubevange:

| Impahla | Insimbi yeManganese ephezulu | I-alloy Steel |

|---|---|---|

| Gqoka Ukumelana | Ivamise ukugqoka ngokushesha ezimeni ezithile | Imelana nokugqoka kangcono, ihlala isikhathi eside |

| Ukumelana Nomthelela | Ukumelana nomthelela omuhle | Ukumelana nomthelela omaphakathi |

| Ukuqina | Ingasebenza-nzima kodwa yehlise ubulukhuni obuphelele | Ukuqina okuphezulu (HRC 48-51) |

| Ukuqina | Ngokuvamile ayihlali isikhathi eside kunensimbi ye-alloy | Ingahlala isikhathi eside izikhathi ezintathu |

| Amandla Okushintsha | Ingashintshwa nge-chromium/molybdenum | Akuvamile ukushintshwa |

Ikhono lokuqinisa umsebenzi lensimbi ephezulu ye-manganese liyivumela ukuthi imunce amandla abalulekile ngesikhathi sokusebenza. Le ndawo ikhulisa ukuqina kwayo, iyenze ifanelekele izicelo ezinomthelela omkhulu ezimayini.

Izindleko-Ngempumelelo

Ukusebenza kahle kwezindleko kungenye inzuzo ebalulekile yensimbi ephezulu ye-manganese. Nakuba ukutshalwa kwezimali kokuqala kungase kube phezulu kunezinye izindlela, ukonga kwesikhathi eside kuvame ukudlula lezi zindleko. Izingxenye zensimbi ye-manganese ephezulu ngokuvamile zinikeza impilo yesevisi eyandisiwe ngokuqhathaniswa nezinye izinto. Lokhu kuphila isikhathi eside kuhumushela ekuncishisweni kwemvamisa yokushintsha kanye nezindleko zokulungisa eziphansi.

Ngaphezu kwalokho, ukusetshenziswa kwensimbi ephezulu ye-manganese kungaholela ekongeni okukhulu ezindlekweni zokusebenza. Izinkampani zinganciphisa isikhathi sokuphumula kanye nezindleko zokulungisa, okunomthelela ekusebenzeni kahle okuphelele. Isibonelo, izingxenye zensimbi ye-chrome alloy ephezulu zingahlala isikhathi eside izikhathi ezintathu kuya kwezine kunezinsimbi ezijwayelekile ze-manganese. Lokhu kuphila okunwetshiwe kunciphisa isidingo sokushintshwa njalo, okuholela ekwehleni kwezindleko eziphelele.

Izicelo Zensimbi Ephakeme YeManganese Ekugayweni Kwezimayini

Ama-Crusher Liners

Insimbi ye-manganese ephezuluidlala indima ebalulekile ekukhiqizeni ama-crusher liners. Lawa ma-liner ayingxenye ebalulekile ezinhlobonhloboizimboni ezigqokwa kakhulu, okuhlanganisa ukumba izinkwali, izimayini, ukumba, kanye nomkhakha wamalahle. Zimelana nokungqubuzana okukhulu kwempahla kanye nomthelela ophihlizayo, ziqinisekisa ukusebenza okuzinzile kwama-crusher. Ukumelana nokugqokwa okuphakeme kanye nempilo yesevisi eyandisiwe yensimbi ephezulu ye-manganese iyenza ifanelekele izinhlelo zokusebenza ezisindayo.

Ithebula elilandelayo ligqamisa ukuthuthukiswa kokusebenza okubonwa lapho kusetshenziswa insimbi ephezulu ye-manganese kuma-crusher liners:

| Ukuthuthukiswa Kokusebenza | Incazelo |

|---|---|

| I-Wear Resistance enhle kakhulu | Umbukiso we-high-manganese steel linersukumelana nokugqoka okukhethekile, inweba impilo yemishini. |

| Izakhiwo Eziziqinisayo | Amalayini akhula ngobulukhuni bobuso ngokuhamba kwesikhathi, athuthukisa ukumelana nokugqoka nokusebenza kahle. |

| Ukusebenza Kwe-Crusher Okuthuthukisiwe | Ukuqina okuphezulu kuholela ekuchobozeni okusebenzayo, ukunciphisa ukulahleka kwamandla kanye nokwenza ngcono umthamo wokukhiqiza. |

| Imvamisa Yokugcinwa Kwezisetshenziswa Eyehlisiwe | Ukwanda kokuqina kwendawo kubangela ukuguga kancane, kunciphisa isidingo sokushintshwa njalo. |

| Ukuthuthukiswa Kwekhono Lokukhiqiza Ngokuphelele | Impilo ende yesevisi kanye nesikhathi esincishisiwe sokuphumula sithuthukisa ukuqhubeka komugqa wokukhiqiza kanye nokukhiqiza okuphelele. |

| Ukumelana Nomthelela Okuqinile | Amalayini amelana nomthelela omkhulu, agcina ukusebenza okuzinzile kanye nokunciphisa izindleko zokuwalungisa. |

| Izindleko Zokusebenza Ezincishisiwe | Ukungalungiswa njalo nokushintshwa kwezindleko kwehlisa izindleko zokusebenza futhi kuthuthukiswe izinzuzo zezomnotho. |

I-Jaw and Cone Crushers

Insimbi ye-manganese ephezulu kakhulukuthuthukisa ukusebenza kwemihlathi nama-cone crushers. Cishe u-70% weumhlathi kanye nama-cone crushersembonini yezimayini sebenzisa izingxenye zensimbi ze-manganese eziphezulu. Lokhu impahla inikezaukuqina nokuqina okungavamile, okubalulekile ekubambeni ukushaqeka ezindaweni ezinengcindezi ephezulu.

Izakhiwo eziyingqayizivele zensimbi ye-manganese ephezulu zivumela ukuthi imunce futhi ihlakaze amandla okwethuka ngempumelelo. Lokhu kuvimbela ukuqhekeka noma ukuphuka, okubalulekile ekucubunguleni izinto eziqinile. Lawa maphuzu alandelayo afingqa izinzuzo zensimbi ephezulu ye-manganese emihlathini nasezitsheni zekhoni:

- Insimbi yeManganese iyaqina ngomthelela ngamunye, ikhulise ukumelana kwayo nokuhuzuka.

- Igcina ukuqina okuphezulu, idonsa amandla omthelela abalulekile ngaphandle kokuqhekeka.

- Le nhlanganisela ivumela ukuthi yenze kahle ezimeni ezilimazayo nezinomthelela ophezulu.

Ngokunciphisa isidingo sokushintshwa kwezingxenye njalo, insimbi ephezulu ye-manganese inciphisa isikhathi sokuphumula futhi ithuthukise ukukhiqiza okuphelele. Ukusebenza kahle kwayo kwezindleko kubangelwa isikhathi eside sokuphila sezingxenye, okuholela ezidingweni zokunakekela eziphansi.

Umthelela Wensimbi YeManganese Ephezulu Ekusebenzeni Kahle Nokukhiqiza

Isikhathi Sokuphumula Esincishisiwe

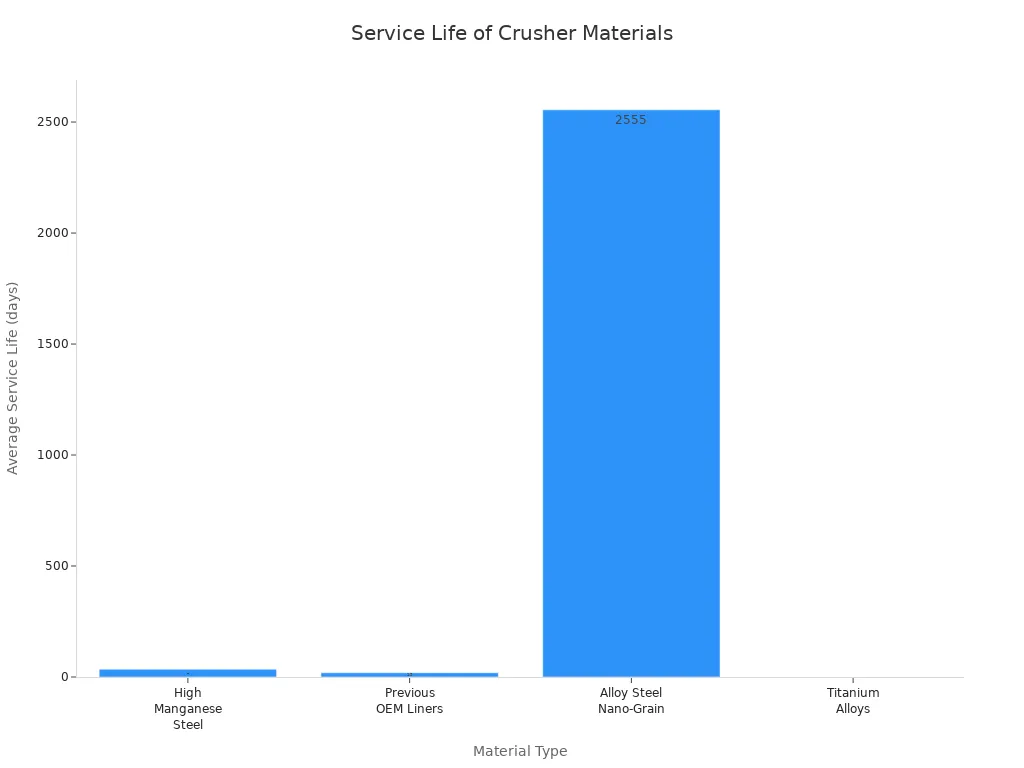

Insimbi ephezulu ye-manganese inciphisa kakhulu isikhathi sokungasebenzi emisebenzini yezimayini. Ukuqina kwayo futhiukumelana nokugqokakuholela empilweni ende yesevisi yezingxenye. Ngokwesibonelo, high manganese steel liners ingahlala isilinganisoizinsuku ezingu-35, uma kuqhathaniswa nezinsuku eziyi-19 kuphela zamalayini e-OEM adlule. Lokhu kuthuthukiswa kuvumela izinkampani zezimayini ukuthi zigcine ukusebenza okuqhubekayo ngaphandle kokuphazamiseka okuvamisile kokushintshwa kwengxenye.

| Uhlobo Lwezinto | Isilinganiso Sempilo Yesevisi | Amanothi |

|---|---|---|

| Insimbi Ye-Manganese Ephakeme (Xtralloy) | izinsuku ezingu-35 | Ukuthuthukiswa okubonakalayo ngaphezu kwamalayini e-OEM adlule. |

| I-OEM Liners yangaphambili | izinsuku ezingu-19 | Impilo yesevisi ephansi uma iqhathaniswa ne-Xtralloy. |

| I-alloy Steel ene-Nano-Grain Forging | Iminyaka engu-5-7 | Ukuphila okude kunensimbi ephezulu ye-manganese. |

| I-Titanium Alloys | Iminyaka engu-7-9 | Ukuphila okuphakeme uma kuqhathaniswa nensimbi ephezulu ye-manganese. |

Ubude besikhathi obunwetshiwe bezingxenye eziphezulu zensimbi ye-manganese buholela ekuvaleni ukunakekelwa okumbalwa. Amaklayenti abike ukwehliswa kwesikhathi sokulungisa kuze kufike30%ngemva kokushintshela ezingxenyeni eziphakeme zensimbi ye-manganese. Lokhu kwehliswa akugcini nje ngokuthuthukisa ukukhiqiza kodwa futhi kunomthelela ekongeni izindleko ezibalulekile.

Amamethrikhi Okusebenza Athuthukisiwe

Insimbi ye-manganese ephezulu ithuthukisa amamethrikhi okusebenza ambalwa kumishini yokuchoboza yezimayini. Izici zayo eziyingqayizivele zithuthukisa ukumelana nokugqoka, ukuqina, nokuqina okuphelele. Ngenxa yalokho, imisebenzi yezimayini inesipiliyoni:

- Gqoka Ukumelana: Insimbi ephezulu ye-manganese iba lukhuni ngokuhamba kwesikhathi uma ibhekene nokungqubuzana, okuyenza ilungele izinhlelo zokusebenza lapho ukuguga kuwukukhathazeka.

- Ukuqina: Ukuqina kwento kuthuthukisa amandla ayo okumelana nomthelela kanye namandla abrasive, okubalulekile ezindaweni zezimayini.

- Ukuqina: Ukuqina sekukonke kuyathuthukiswa, okuholela ekwehliseni isikhathi sokuphumula kanye nezindleko zokunakekela eziphansi.

Imodeli yokubikezela impilo yonke yamapuleti ahlabayo ibonisa impande ephansi yephutha lesikwele (RMSE) ye0.0614 amahora. Lokhu kunemba kukhombisa ukuthi insimbi ephezulu ye-manganese ikhulisa kakhulu ukukhiqiza, impilo esukela emahoreni angama-746 kuye kwangama-6902. Izinkampani ezigxile ezingxenyeni zekhwalithi zithola ukuthuthukiswa kokukhiqiza okungafika ku-20%.

Ngokutshala imali ezingxenyeni eziphezulu zensimbi ye-manganese, imisebenzi yezimayini ingafinyelela amamethrikhi okusebenza angcono nokusebenza kahle.

Insimbi ye-manganese ephezuluIzakhiwo zikwenza kube semqoka ezinhlelweni zokuchotshozwa kwezimayini. Ukwakheka kwayo okuyingqayizivele kuthuthukisa ukuqina, ukumelana nokugqoka, kanye nokuqina. Lokhu okubalulekile kuthuthukisa kakhulu ukukhiqiza nokonga kwezindleko zemisebenzi yezimayini. Izinzuzo ezibalulekile zifaka:

- Izikhawu zokulungisa ezinwetshiwe ngo30–40%

- Ukuvama okuncishisiwe kokushintshwa kwengxenye

- Izindleko zokusebenza eziphansi

Isidingo sensimbi ephezulu ye-manganese siyikulindeleke ukuthi ikhuphukengenxa yokusebenza kwayo okungenakuqhathaniswa ezimeni ezinzima. Njengoba ubuchwepheshe bezimayini buthuthuka, ukusetshenziswa okuqhubekayo kwensimbi ephezulu ye-manganese kusabalulekile ekusebenzeni kahle.

| Isakhiwo/Umsebenzi | Incazelo |

|---|---|

| I-ejenti ye-Deoxidizing | Ikhipha umoya-mpilo kanye nesibabule ukungcola ensimbi encibilikisiwe, ithuthukisa amandla nokuqina. |

| I-alloy Strengthener | Ithuthukisa ukuqina, ubulukhuni, nokumelana nokugqoka ngokwenza izinhlanganisela ezizinzile ngekhabhoni. |

| I-Hardenability Booster | Kwandisa ukuqina, okwenza insimbi ifaneleke izicelo zesakhiwo ngaphansi kokucindezeleka. |

| Insimbi Ye-Manganese Ephakeme | Iqukethe ama-manganese angu-12–14%, aziwa ngezinto ezingavamile eziqinisa umsebenzi, elungele ukumbiwa. |

FAQ

Iyini insimbi ephezulu ye-manganese?

Insimbi ye-manganese ephezulu iyingxubevange equkethe i-11-14% ye-manganese. Yaziwa ngokuqina kwayo okukhethekile kanye nokumelana nokugqoka, okuyenza ilungele izicelo zezimayini.

Ngabe insimbi ephezulu ye-manganese isebenza kanjani kanzima?

Ukusebenza kwensimbi ephezulu ye-manganese kuyaqina uma kunomthelela. Le nqubo ikhulisa ubulukhuni bayo, ivumela ukuthi ibambe amandla amaningi futhi imelane nokugqoka.

Yiziphi izinto ezisetshenziswa kakhulu zensimbi ephezulu ye-manganese ezimayini?

Insimbi ephezulu ye-manganese isetshenziswa ngokuyinhloko kuma-crusher liners,ama-crushers emihlathini, kanye nama-cone crushers. Ukuqina kwayo kuyenza ifanelekele izindawo ezinomthelela omkhulu kanye nezibi.

Kungani insimbi ephezulu ye-manganese ibiza kakhulu?

Nakuba insimbi ephezulu ye-manganese ingaba nezindleko eziphakeme zokuqala, impilo yayo ende yesevisi kanyeizidingo zokunakekela ezincishisiwekuholela ekongeni okukhulu ngokuhamba kwesikhathi.

Insimbi ephezulu ye-manganese iqhathaniswa kanjani nezinye izinto?

Insimbi ye-manganese ephezulu inikeza ukumelana nokugqoka okuphezulu nokuqina uma kuqhathaniswa nezinye izinto ezifana nensimbi ye-alloy. Lokhu kwenza kube ukukhetha okuncanyelwayo kokufuna izicelo zokumba izimayini.

Isikhathi sokuthumela: Oct-24-2025