Incazelo

Ukuze ukhiqize imikhiqizo yokugcina yekhwalithi ephezulu ngezindleko eziphansi ngokusebenza kahle kakhulu nokwethembeka, kufanele ukhethe izingxenye ezigugile ezilungiselelwa uhlelo lwakho lokusebenza oluthile lokuchoboza. Izici ezibalulekile okufanele zicatshangelwe kanje:

1. Uhlobo lwamatshe noma amaminerali okufanele achotshozwe.

2. Usayizi wezinhlayiyana zezinto ezibonakalayo, okuqukethwe umswakama kanye nebanga lobulukhuni be-Mohs.

3. Izinto kanye nempilo yamabha okushaya asetshenziswe ngaphambilini.

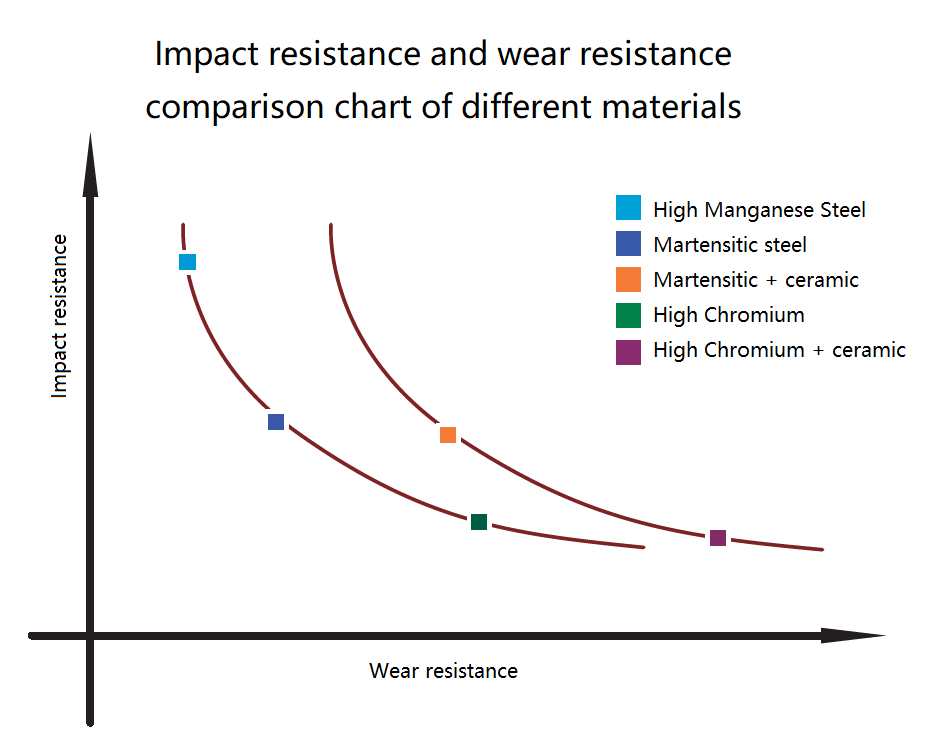

Ngokuvamile, ukumelana nokugqokwa (noma ubulukhuni) bezinto ezifakwa odongeni zensimbi ezingagqoki kuzonciphisa nakanjani ukumelana nomthelela (noma ukuqina). Indlela yokushumeka izitsha zobumba ezintweni ze-matrix yensimbi ingakhuphula kakhulu ukumelana kwayo nokugqoka ngaphandle kokuphazamisa ukumelana nomthelela wayo.

Insimbi yeManganese ephezulu

Insimbi ye-manganese ephezulu iyinto engagugi enomlando omude futhi isetshenziswe kakhulu kuma-crushers anethonya. Insimbi ye-manganese ephezulu inokumelana nomthelela ovelele. Ukumelana nokugqoka ngokuvamile kuhlobene nokucindezela kanye nomthelela ebusweni bawo. Uma kusetshenziswa umthelela omkhulu, isakhiwo se-austenite esingaphezulu singaqiniswa sibe yi-HRC50 noma ngaphezulu.

Izando zepuleti lensimbi ye-manganese ephezulu ngokuvamile zinconywa kuphela ukuchotshozwa okuyisisekelo ngezinto ezinosayizi wezinhlayiyana ezinkulu zokuphakelayo kanye nobulukhuni obuphansi.

Ukwakhiwa kwamakhemikhali ensimbi ephezulu ye-manganese

| Okubalulekile | Ukwakheka Kwamakhemikhali | Impahla Yemishini | ||||

| Mn% | Cr% | C% | Si% | Ak/cm | HB | |

| Mn14 | 12-14 | 1.7-2.2 | 1.15-1.25 | 0.3-0.6 | > 140 | 180-220 |

| Mn15 | 14-16 | 1.7-2.2 | 1.15-1.30 | 0.3-0.6 | > 140 | 180-220 |

| Mn18 | 16-19 | 1.8-2.5 | 1.15-1.30 | 0.3-0.8 | > 140 | 190-240 |

| Mn22 | 20-22 | 1.8-2.5 | 1.10-1.40 | 0.3-0.8 | > 140 | 190-240 |

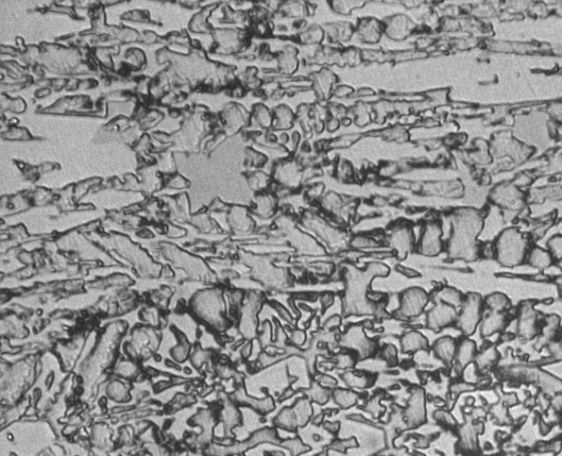

I-Microstructure yensimbi ephezulu ye-manganese

Insimbi ye-Martensitic

Isakhiwo se-Martensite sakhiwe ngokupholisa ngokushesha kwensimbi ye-carbon egcwele ngokugcwele. Ama-athomu e-carbon angasakazeka ngaphandle kwe-martensite kuphela ngenqubo yokupholisa ngokushesha ngemva kokwelashwa kokushisa. Insimbi ye-Martensitic inobulukhuni obuphakeme kunensimbi ye-manganese ephezulu, kodwa ukumelana kwayo komthelela kuyehla ngokufanayo. Ukuqina kwensimbi ye-martensitic kuphakathi kwe-HRC46-56. Ngokusekelwe kulezi zakhiwo, ibha yokuvuthela yensimbi ye-martensitic ngokuvamile iyanconywa ukuze kugxotshwe izinhlelo zokusebenza lapho umthelela ophansi kakhulu kodwa ukumelana nokugqokwa okuphezulu kuyadingeka.

I-Microstructure yensimbi ye-martensitic

Insimbi Emhlophe Ye-Chromium Ephakeme

Ensimbi emhlophe ye-chromium ephezulu, ikhabhoni ihlanganiswa ne-chromium ngendlela ye-chromium carbide. Insimbi emhlophe ye-chromium ephezulu inokumelana nokugqokwa okuvelele. Ngemuva kokwelashwa okushisa, ubulukhuni bayo bungafinyelela ku-60-64HRC, kodwa ukumelana nomthelela wayo kuyancipha ngendlela efanayo. Uma kuqhathaniswa nensimbi ephezulu ye-manganese nensimbi ye-martensitic, insimbi ephezulu ye-chromium inokumelana okuphezulu kakhulu nokugqokwa, kodwa ukumelana kwayo komthelela nakho kuphansi kakhulu.

Ensimbi emhlophe ye-chromium ephezulu, ikhabhoni ihlanganiswa ne-chromium ngendlela ye-chromium carbide. Insimbi emhlophe ye-chromium ephezulu inokumelana nokugqokwa okuvelele. Ngemuva kokwelashwa okushisa, ubulukhuni bayo bungafinyelela ku-60-64HRC, kodwa ukumelana nomthelela wayo kuyancipha ngendlela efanayo. Uma kuqhathaniswa nensimbi ephezulu ye-manganese nensimbi ye-martensitic, insimbi ephezulu ye-chromium inokumelana okuphezulu kakhulu nokugqokwa, kodwa ukumelana kwayo komthelela nakho kuphansi kakhulu.

Ukwakheka kwamakhemikhali ensimbi emhlophe ye-chromium ephezulu

| I-ASTM A532 | Incazelo | C | Mn | Si | Ni | Cr | Mo | |

| I | A | I-Ni-Cr-Hc | 2.8-3.6 | 2.0 Ubukhulu | 0.8 ubuningi | 3.3-5.0 | 1.4-4.0 | 1.0 Ubukhulu |

| I | B | I-Ni-Cr-Lc | 2.4-3.0 | 2.0 Ubukhulu | 0.8 ubuningi | 3.3-5.0 | 1.4-4.0 | 1.0 Ubukhulu |

| I | C | I-Ni-Cr-GB | 2.5-3.7 | 2.0 Ubukhulu | 0.8 ubuningi | 4.0 Max | 1.0-2.5 | 1.0 Ubukhulu |

| I | D | I-Ni-HiCr | 2.5-3.6 | 2.0 Ubukhulu | 2.0 Ubukhulu | 4.5-7.0 | 7.0-11.0 | 1.5 ubuningi |

| II | A | 12Kr | 2.0-3.3 | 2.0 Ubukhulu | 1.5 ubuningi | 0.40-0.60 | 11.0-14.0 | 3.0 Ubukhulu |

| II | B | 15CrMo | 2.0-3.3 | 2.0 Ubukhulu | 1.5 ubuningi | 0.80-1.20 | 14.0-18.0 | 3.0 Ubukhulu |

| II | D | 20CrMo | 2.8-3.3 | 2.0 Ubukhulu | 1.0-2.2 | 0.80-1.20 | 18.0-23.0 | 3.0 Ubukhulu |

| III | A | 25Kr | 2.8-3.3 | 2.0 Ubukhulu | 1.5 ubuningi | 0.40-0.60 | 23.0-30.0 | 3.0 Ubukhulu |

I-Microstructure Yensimbi Emhlophe Ye-Chromium Ephezulu

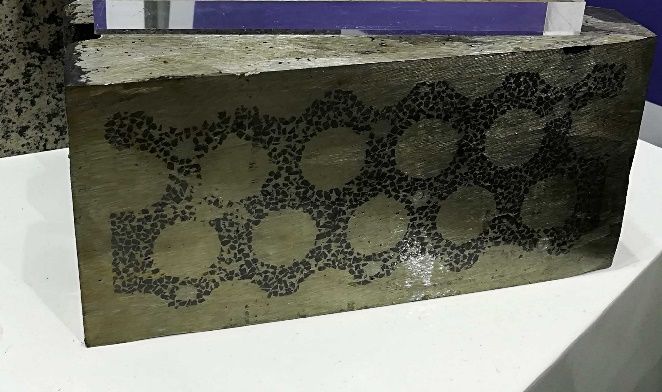

I-Ceramic-Metal Composite Material (CMC)

I-CMC iwumsebenzi ongagqoki ohlanganisa ukuqina okuhle kwezinto zensimbi (insimbi ye-martensitic noma i-high-chromium cast iron) nokuqina okuphezulu kakhulu kwezitsha zobumba zemboni. Izinhlayiya ze-Ceramic zosayizi othize ziphathwa ngokukhethekile ukuze zenze umzimba we-porous wezinhlayiya ze-ceramic. Insimbi encibilikisiwe ingena ngokuphelele phakathi kwe-interstices yesakhiwo se-ceramic ngesikhathi sokubunjwa futhi ihlangana kahle nezinhlayiya zobumba.

Lo mklamo ungathuthukisa ngokuphumelelayo ukusebenza okuphambene nokugqoka kobuso obusebenzayo; ngesikhathi esifanayo, indikimba eyinhloko ye-blow bar noma isando isenziwe ngensimbi ukuze kuqinisekiswe ukusebenza kwayo okuphephile, ukuxazulula ngokuphumelelayo ukuphikisana phakathi kokumelana nokugqoka kanye nokumelana nomthelela, futhi ingashintshwa ukuze ihambisane nezimo ezihlukahlukene zokusebenza. Ivula insimu entsha yokukhethwa kwezingxenye ezisele ezigqokwa kakhulu zabasebenzisi abaningi, futhi idale izinzuzo ezingcono zezomnotho.

a.Martensitic Steel + Ceramic

Uma kuqhathaniswa nebha evamile ye-martensitic blow, isando se-martensitic sobumba sinobulukhuni obuphakeme endaweni egugile, kodwa ukumelana komthelela wesando sokushaywa ngeke kwehle. Ezimweni zokusebenza, ibha yokuvuthela ye-martensitic ceramic ingaba indawo enhle yohlelo futhi ngokuvamile ingathola cishe izikhathi ezi-2 noma impilo yesevisi ende.

b.I-Chromium White Iron +Ceramic ephezulu

Nakuba i-high-chromium iron blow bar evamile isivele inokumelana nokugqokwa okuphezulu, lapho izinto zokuphahlazeka ezinobunzima obuphakeme kakhulu, njengegwadle, imigoqo yokushaya engagugi kakhulu ivame ukusetshenziselwa ukwelula impilo yazo yokusebenza. Kulesi simo, insimbi ephezulu ye-chromium ene-blow bar ye-ceramic efakiwe iyisixazululo esingcono. Ngenxa yokushumeka kwe-ceramics, ubulukhuni bokugqoka kwesando sokushaywa buyanda, futhi ukumelana kwayo nokugqoka kuthuthukiswa kakhulu, ngokuvamile izikhathi ezingu-2 noma impilo yesevisi ende kunensimbi evamile ephezulu ye-chromium emhlophe.

Ubuhle be-Ceramic-Metal Composite Material (CMC)

(1) Iqinile kodwa ayishwabanisi, iqinile futhi ayigugi, ifinyelela ibhalansi ekabili yokumelana nokuguga kanye nokuqina okuphezulu;

(2) Ubulukhuni be-ceramic buyi-2100HV, futhi ukumelana nokugqoka kungafinyelela izikhathi ezingu-3 kuya kwezi-4 zezinto ezijwayelekile ze-alloy;

(3) Idizayini yesikimu esiqondene nawe, ulayini wokugqoka onengqondo;

(4) Impilo ende yesevisi kanye nezinzuzo eziphezulu zezomnotho.

Ipharamitha Yomkhiqizo

| Umshini Brand | Imodeli yomshini |

| Metso | I-LT-NP 1007 |

| I-LT-NP 1110 | |

| I-LT-NP 1213 | |

| I-LT-NP 1315/1415 | |

| I-LT-NP 1520/1620 | |

| I-Hazemag | 1022 HAZ791-2 HAZ879 HAZ790 HAZ893 HAZ975 HAZ817 |

| 1313 HAZ796 HAZ857 HAZ832 HAZ879 HAZ764 HAZ1073 | |

| 1320 HAZ1025 HAZ804 HAZ789 HAZ878 HAZ800A HAZ1077 | |

| 1515 HAZ814 HAZ868 HAZ1085 HAZ866 HAZ850 HAZ804 | |

| 791 HAZ565 HAZ667 HAZ1023 HAZ811 HAZ793 HAZ1096 | |

| 789 HAZ815 HAZ814 HAZ764 HAZ810 HAZ797 HAZ1022 | |

| Sandvik | I-QI341 (QI240) |

| I-QI441(QI440) | |

| I-QI340 (I-C13) | |

| I-CI124 | |

| I-CI224 | |

| Kleemann | I-MR110 EVO |

| I-MR130 EVO | |

| MR100Z | |

| I-MR122Z | |

| Terex Pegson | I-XH250 (CR004-012-001) |

| I-XH320-entsha | |

| I-XH320 ubudala | |

| 1412 (XH500) | |

| 428 Tracpactor 4242 (300 high) | |

| Isikrini samandla | I-Trackpactor 320 |

| Terex Finlay | I-100 |

| I-110 | |

| I-120 | |

| I-130 | |

| I-140 | |

| I-Rubblemaster | RM60 |

| RM70 | |

| RM80 | |

| I-R100 | |

| RM120 | |

| I-Tesab | I-RK-623 |

| I-RK-1012 | |

| I-Extec | C13 |

| I-Telsmith | 6060 |

| I-Keestrack | R3 |

| R5 | |

| McCloskey | I44 |

| I54 | |

| Lippmann | 4248 |

| Ukhozi | 1400 |

| 1200 | |

| Umgadli | 907 |

| 1112/1312 -100mm | |

| 1112/1312 -120mm | |

| 1315 | |

| Kumbee | No1 |

| No2 | |

| Shanghai Shanbao | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| SBM/Henan Liming/Shanghai Zenith | PF-1010 |

| PF-1210 | |

| PF-1214 | |

| PF-1315 | |

| PFW-1214 | |

| PFW-1315 |