Insimbi yeManganese isiguqule i-metallurgy nezimboni ezisindayo ngamandla ayo akhethekile nokuqina. Itholwe nguSir Robert Hadfield ngo-1882, le ngxubevange ihlanganisa insimbi, ikhabhoni, ne-manganese ukuze kwakhiwe into ehlukile kuzo zonke ezinye. Ikhono layo eliyingqayizivele lokuqina ngaphansi komthelela liyenze yashintsha umdlalo wamathuluzi, imishini, nezinhlelo zokusebenza zokwakha.

Izici eziphawulekayo zensimbi ye-manganese zisuka endimeni ebalulekile ye-manganese ekwenzeni insimbi. Akugcini nje ngokuqeda ukungcola njengesibabule ne-oxygen, kodwa futhi kuthuthukisa kakhulu ubulukhuni nokumelana nokugqoka. Ngokuhamba kwesikhathi, intuthuko efana nokwelashwa kokushisa kanye nezindlela zokukhiqiza ezisezingeni eliphezulu ziye zandisa amathuba okubaishidi lensimbi ye-manganese, ipuleti lensimbi ye-manganese, futhiama-manganese steel liners.

Namuhla, insimbi ye-manganese kanyeipuleti lensimbi ye-manganeseukuqhubeka nokusebenza njengezisetshenziswa eziyisisekelo ezimbonini ezifuna ukumelana nomthelela omkhulu, okuhlanganisa izimayini nezitimela.

Okuthathwayo Okubalulekile

- Insimbi ye-Manganeseyasungulwa nguSir Robert Hadfield ngo-1882.

- Inamandla kakhulu futhi iba nzima uma ishaywa, iyenze ibe yinhle emisebenzini enzima.

- Inqubo ye-Bessemer yenza insimbi ye-manganese ibe ngcono ngokususa ukungcola.

- Le nqubo yenza insimbi iqine futhi ihlale isikhathi eside.

- Insimbi yeManganese isetshenziswa ezimayini, ezitimeleni, nasekwakhiweni ngenxa yalokhoimelana nokugqoka.

- Ukuqina kwayo kusiza ukunciphisa izindleko zokulungisa futhi kwenza imishini ihlale isikhathi eside.

- Izindlela ezintsha zokuxuba ama-alloys nokwenza insimbi ithuthukise ukusebenza kwayo namuhla.

- Ukugaywa kabusha kwensimbi ye-manganese kubalulekile ekongeni izinsiza nasekusizeni iplanethi.

Umsuka Wensimbi YeManganese

Ukutholwa kukaSir Robert Hadfield

Indaba yensimbi ye-manganese iqala ngo-Sir Robert Hadfield, isazi sensimbi saseBrithani owathola into edabukisayo ngo-1882. Wathola ukuthi ukungeza i-manganese ensimbi kwakha ingxubevange enezinto ezingavamile. Ngokungafani nensimbi yendabuko, le nto entsha yayiqinile futhi iqinile, iyenza ilungele ukusetshenziswa okunomthelela ophezulu.

Umsebenzi kaHadfield wawungenazo izinselele. Ekuqaleni, waqaphela ukuthi insimbi ye-manganese imelana nomshini futhi yayingakwazi ukuvaleka, okwenza kube nzima ukusebenza ngayo. Nokho, lezi zithiyo azizange zimthene amandla. Kunalokho, bagqamisa ubunjalo obuyingqayizivele bengxubevange namandla ayo okuguqula izimboni.

- Ukuqina kwensimbi ye-Manganese kanye nezinto eziziqinisayo zenza ihluke kwezinye izinto.

- Okutholwe nguHadfield kugcizelele i-manganese njengento eyinhloko ebhekele lezi zici eziphawulekayo.

Izivivinyo Zangaphambili Nokuthuthukiswa Kwengxubevange

Ukutholwa kuka-Hadfield kwavusa igagasi lokuhlola ukuze kucwengwe ingxubevange nokuqonda ukuziphatha kwayo. Abacwaningi bagxile endleleni i-manganese esebenzisana ngayo nezinye izakhi ezifana nekhabhoni nensimbi. Lezi zifundo zakuqala zabeka isisekelo sensimbi yemanganese esiyaziyo namuhla.

Umkhuba wakuqala wokubhekana nezinsimbi zensimbi yemanganese kusukela ngonyaka ka-1887 kuya phambili wawuwukushisa izingothi zishise kakhulu kunamazinga okushisa uMnu. Potter abhekisela kuwo. Esikhathini eside ngaphambi konyaka ka-1900 kwakhiqizwa futhi kwasetshenziswa izinkulungwane eziningi zamathani emikhiqizo enjalo engumgunyathi negoqiwe. Ephepheni elethulwe kulesi Sikhungo ngumbhali ngo-1893, elinesihloko esithi Iron Alloys, neSpecial Reference yeManganese Steel, imininingwane egcwele nezithombe kukhonjiswa ngensimbi yemanganese ekhandwe yaba ama-asi kaloliwe bese igingqika ibe ngamathayi kaloliwe.

Njengoba abacwaningi bezama, bathola imininingwane ethakazelisayo mayelana nokuguquka kwesigaba sengxubevange kanye nesakhiwo esincane. Ngokwesibonelo, olunye ucwaningo lwahlola ingxubevange ye-medium-manganese eklanyelwe ukwakhiwa. Okutholakele kuveze ukuthi amazinga okushisa kanye nezikhathi zokucwiliswa emanzini zibe nomthelela kanjani ezintweni ezibonakalayo:

| Okutholakele | Incazelo |

|---|---|

| Izinguquko zesigaba | Ucwaningo lugxile ekushintsheni kwesigaba ku-alloy-Mn emaphakathi, ikakhulukazi i-0.19C-5.4Mn-0.87Si-1Al, eyenzelwe ukufogina. |

| Ukungezwani | Ucwaningo lugqamise ukungezwani phakathi kokulingiswa kwe-thermodynamic nemiphumela yokuhlola, kugcizelela isidingo sokucatshangelwa ngokucophelela kwamazinga okushisa, izikhathi zokucwiliswa emanzini, kanye ne-microstructure yokuqala. |

Lezi zivivinyo zisize ekucwebiseni ukwakheka kwensimbi ye-manganese, kwenze ukuthi ithembeke kakhudlwana futhi isebenzise izinto ezihlukahlukene ukuze isetshenziswe ezimbonini.

Ubunikazi kanye Nezicelo Zokuqala

Umsebenzi kaHadfield wafinyelela umvuthwandaba ekugunyazweni kobunikazi beinsimbi ye-manganesengo-1883. Lokhu kwaphawula ukuqala kohambo lwayo lokusebenzisa izinto ezingokoqobo. Ikhono lengxubevange yokuqina ngaphansi kokusebenza kwalo liyenze yashintsha umdlalo ezimbonini ezinjengezimayini nezitimela.

Okunye ukusetshenziswa kwakuqala kwensimbi ye-manganese kwakukumathrekhi wesitimela nama-ekseli. Ukuqina kwayo nokumelana nokugqokwa kwayo kwayenza yaba ilungele ukuphatha imithwalo esindayo kanye nokungqubuzana okuqhubekayo kwezitimela. Ngokuhamba kwesikhathi, abakhiqizi baqala ukuyisebenzisela abanyeamathuluzi aphezulukanye nemishini, ngokuqhubekayo iqinisa indawo yayo emlandweni wezimboni.

Ukuqamba okusha kukaHadfield akuzange nje kudale into entsha; kwavula umnyango wenkathi entsha ye-metallurgy. Insimbi yeManganese yaba uphawu lwenqubekelaphambili, okufakazela ukuthi isayensi nezimboni zingasebenzisana ukuze kuxazululwe izinkinga zomhlaba wangempela.

Intuthuko kuManganese Steel Technology

Inqubo Ye-Bessemer Nendima Yayo

IInqubo ye-Bessemeribambe iqhaza elibalulekile ekuthuthukisweni kokuqala kwensimbi ye-manganese. Le ndlela entsha yokwenza insimbi, eyethulwa maphakathi nekhulu le-19, yavumela abakhiqizi ukuthi bakhiqize insimbi ngokuphumelelayo ngokususa ukungcola okunjengekhabhoni ne-silicon. Lapho uSir Robert Hadfield ehlola i-manganese ngensimbi, inqubo ye-Bessemer yaba ithuluzi eliyinhloko lokucwenga i-alloy.

Ngokuhlanganisa i-manganese enqubweni, abakhi bensimbi bangakha into enamandla athuthukisiwe nokuqina. Le nqubo yasiza futhi ekuqedeni isibabule nomoya-mpilo, okwakuvame ukwenza insimbi evamile ibe buthaka. Lokhu kuphumelela kwabeka isisekelo sokwamukelwa kabanzi kwensimbi ye-manganese ekusetshenzisweni kwezimboni.

Kuchazwe Izakhiwo Zokuqinisa Umsebenzi

Esinye sezici ezithakazelisa kakhulu zensimbi ye-manganese amandla ayo okuqina ngaphansi komthelela. Lesi sakhiwo, esibizwa ngokuthi ukuqina komsebenzi, senzeka lapho okokusebenza kuguquguquka. Njengoba indawo engaphezulu ibhekana nengcindezi, iba namandla futhi imelane nokugqokwa.

Ucwaningo lubonise ukuthi lo mphumela uthonywa izici ezifana nezinga lokushisa kanye ne-microstructure yezinto. Isibonelo, ucwaningo lwe-low-carbon, high-manganese steels luveze ukuthi ukusonteka kwemishini kanye nokuguqulwa kwe-martensitic kuthuthukisa kakhulu amandla kanye ne-ductility.

| Isici | Incazelo |

|---|---|

| Okubalulekile | Izinsimbi ze-Low-C eziphezulu ze-manganese |

| Amazinga Okushisa Okuguquguqukayo | -40 °C, 20 °C, 200 °C |

| Okubhekwayo | Ukuguqulwa okubangelwa ubunzima kanye ne-twinning yemishini kuthuthukisa izakhiwo. |

| Okutholakele | Izinga lokushisa lithinta ukuziphatha kokuqina kwengcindezi kanye nokuvela kwe-microstructure. |

Lesi sakhiwo esiyingqayizivele senza insimbi ye-manganese ilungele izindawo ezinomthelela omkhulu njengezimayini nokwakha.

Ukuthuthukiswa Kokubunjwa Kwengxubevange

Ngokuhamba kweminyaka, abacwaningi baye benza kanjalokucwengisiswe ukwakhekayensimbi ye-manganese ukuthuthukisa ukusebenza kwayo. Ukwengezwa kwezinto ezifana ne-aluminium ne-silicon kuholele entuthukweni ebalulekile. Isibonelo, ukwandisa okuqukethwe kwe-aluminium kuthuthukisa amandla okukhiqiza kanye nokumelana nokuguga, nakuba kungase kunciphise i-ductility.

| Ukwakhiwa kwe-alloy | Izinga Lokushisa Lokwelapha | Gqoka Ukumelana | Okutholakele |

|---|---|---|---|

| I-silicon | 700 °C | Kuthuthukisiwe | Ukumelana nokugqokwa okungcono kakhulu ngaphansi komthwalo omthelela omkhulu. |

| Medium Manganese Steel | Okuhlukahlukene | Ihlaziywe | Uhlaka oluxhumanisa ukwakheka kanye nezakhiwo. |

Lokhu kulungiswa kwenze insimbi ye-manganese yasebenza ngezindlela eziningi, okuqinisekisa ukuthi ihlala iyisisekelo semboni yesimanje.

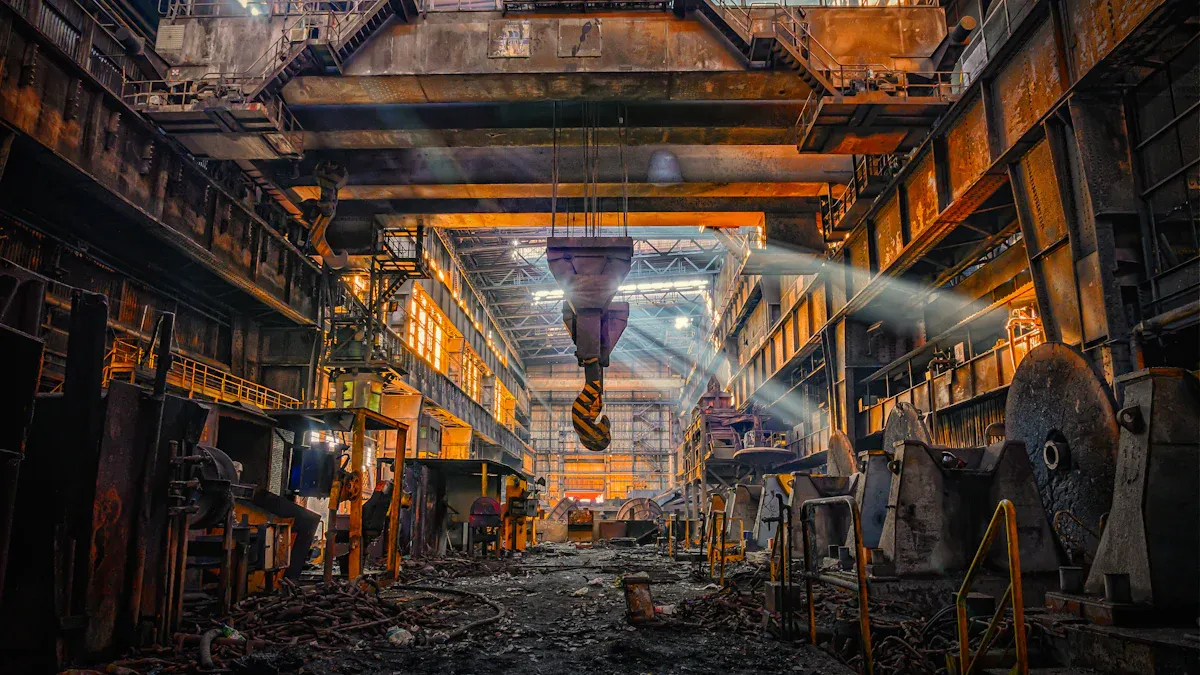

Izicelo zezimboni zeManganese Steel

Izinsiza Zezimayini Nezinkwali

Insimbi yeManganese idlala indima ebalulekile emsebenzini wokumba kanye nokumbiwa kwenkwali. Ukumelana nokugqokwa kwayo okuphezulu kanye nekhono lokuqina ngaphansi komthelela kuyenza into yokuya ezintweni zokusebenza ebhekana nezimo ezibucayi nsuku zonke. Amathuluzi nemishini kulezi zimboni ngokuvamile ibhekana nezinto ezilumayo, imithwalo esindayo, nokungqubuzana okuqhubekayo. Insimbi yeManganese ikhuphukela enseleleni, yelula isikhathi sokuphila kwemishini futhi yehlise nezindleko zokuyilungisa.

Nazi ezinye izinhlelo zokusebenza ezijwayelekile:

- Imihlathi ye-crusher: Lezi zingxenye zichoboza amatshe nensimbi, zibekezelela ukucindezela okukhulu nomthelela. Insimbi ye-Manganese iqinisekisa ukuthi zihlala isikhathi eside.

- Izikrini ze-grizzly: Isetshenziselwa ukuhlunga izinto, lezi zikrini zizuza ekuqina kwensimbi ye-manganese kanye nokumelana nokugqokwa.

- Amatshe amatshe: Lezi ziteshi ziqondisa izinto emishinini, lapho insimbi ye-manganese ivimbela ukuguguleka ekugelezeni njalo.

- Amabhakede efosholo: Ezimayini, amabhakede amafosholo athatha imithwalo esindayo yamatshe nemfucumfucu. Insimbi yeManganese iwagcina eqinile futhi ethembekile.

Ngokusebenzisa insimbi ye-manganese kulezi zinhlelo zokusebenza, izimboni zonga isikhathi nemali ngenkathi zigcina ukusebenza kahle. Izakhiwo zayo eziyingqayizivele ziyenza ibaluleke kakhulu emsebenzini wokumba izimayini nokumba izinkwali.

Amathrekhi Omzila Wesitimela Nemishini Enzima

Ojantshi besitimela bathembele ensimbi ye-manganese ngamathrekhi abo kanye nezingxenye zabo. Ukuqina kwale nto kanye nokumelana nokuguga kuyenza ifaneleke ukuphatha ukungqubuzana okungapheli kanye nemithwalo esindayo yezitimela. Ukwandiswa komhlaba wonke kanye nokwenziwa kwesimanjemanje kwamanethiwekhi ezitimela kuye kwakwandisa isidingo sakho.

Imibiko evela emakethe yensimbi ye-austenitic manganese igqamisa ukusetshenziswa kwayo okusabalele emkhakheni wezitimela. Abakhiqizi bayisebenzisela ukukhiqiza amathrekhi aqinile, amaswishi, neziphambano ezingamelana nemithelela ephindaphindiwe. Ikhono layo lokubekezelela lezi zimo liqinisekisa ukusebenza kahle futhi linciphisa isidingo sokushintshwa njalo.

Ukukhula kwemboni yezitimela kukhuphule nesidingo sensimbi ye-manganese emishinini emikhulu. Izitimela nezimoto ezithwala impahla zidinga izingxenye ezikwazi ukubhekana nokucindezeleka okukhulu nomthelela. Insimbi yeManganese iletha ukusebenza okungenakuqhathaniswa, ikwenze kube ukukhetha okuncanyelwayo kulezi zinhlelo zokusebenza.

Ukutshalwa kwezimali kwingqalasizinda yezokuthutha kuyaqhubeka nokugqugquzela ukuqanjwa kabusha kobuchwepheshe bensimbi ye-manganese. Njengoba imizila yezitimela ikhula, le mpahla isalokhu iyinsika yemboni, iqinisekisa ukusebenza kahle nokwethembeka.

Amathuluzi Okwakha kanye Nomthelela Omkhulu

Izindawo zokwakha ziyizimo ezinzima, futhi amathuluzi asetshenziswa lapho adinga ukuqina nakakhulu. Insimbi ye-Manganese iyakhanya kulo mkhakha, inikeza ukuqina okungenakuqhathaniswa kanye nokumelana nomthelela. Kusukela kumishini yokubhidliza kuya kumazinyo e-excavator, ukusetshenziswa kwayo kubanzi futhi kuhlukahlukene.

Thatha amathuluzi aphezulu, isibonelo. Izingcezu ze-Jackhammer kanye nemiphetho enqunyiwe zibhekana nengcindezi eqhubekayo ngesikhathi sokusetshenziswa. Insimbi yeManganese iqinisekisa ukuthi zihlala zibukhali futhi zisebenza, ngisho nangemva kokuchayeka isikhathi eside ezindaweni eziqinile. Ngokufanayo, imishini yokwakha efana nogandaganda nezilayishi ziyazuza ekhonweni lensimbi ye-manganese ukumelana nokuguga.

Ngaphezu kwamathuluzi, insimbi ye-manganese isetshenziswa ezingxenyeni zesakhiwo. Amabhuloho, amagida, nezinye izakhi ezithwala imithwalo zithembele emandleni alo ukuze ligcine ukuzinza ngaphansi kwemithwalo esindayo. Ukuguquguquka kwayo kuyenza ibe yimpahla ebalulekile ekwakhiweni, lapho ukuqina nokuthembeka kungaxoxiswana khona.

Ngokuhlanganisa insimbi ye-manganese ekwakhiweni namathuluzi anomthelela omkhulu, izimboni zingabhekana namaphrojekthi adingeka kakhulu ngokuzethemba. Izakhiwo zayo eziyingqayizivele ziyenza ibe yinto ethenjwa abakhi nonjiniyela.

Ukuqhathanisa Insimbi YeManganese Nezinye Izinto

Izinzuzo Zokuqina Nokumelana Nomthelela

Insimbi yeManganese igqama ngokuqina kwayo okukhethekile nekhono lokumelana nomthelela. Ukwakheka kwayo okuyingqayizivele, okuhlanganisaamazinga aphezulu we-manganesekanye nekhabhoni, ivumela ukuthi iqine ngaphezulu ngenkathi igcina inkaba eqinile. Le nhlanganisela iyenza ilungele izindawo ezinomthelela omkhulu njengezimayini nokwakha.

Ngokungafani nezinye izinto eziningi, insimbi ye-manganese ingamunca amandla abalulekile ngaphansi kokucindezeleka. Le ndawo, eyaziwa ngokuthi ukuqina komsebenzi, ithuthukisa ukumelana kwayo nokugqokwa ngokuhamba kwesikhathi. Isibonelo, ezinhlelweni ezibandakanya ukugwaza noma ukuhuzuka kokucindezeleka okukhulu, indawo engaphezulu yezinto ezibonakalayo iba namandla ngokusetshenziswa. Nokho, ukusebenza kwayo kungahluka kuye ngezimo. Ngaphansi kwemithwalo emaphakathi noma enomthelela omncane, insimbi ye-manganese ingase ingaqini ngokuphumelelayo, okungakhawulela ukuqina kwayo ezimeni ezinjalo.

Ucwaningo lubonisa ukuthi insimbi ye-manganese, eyaziwa nangokuthi i-Hadfield steel, idlula ezinye izinto ezisetshenziswayo ekuphikisweni kokugqokwa ngaphansi kwezimo zomthelela omkhulu. Ikhono layo lokuzinzisa isigaba se-austenitic liphinde libe nomthelela ekuqina kwayo kanye nokusebenza kahle kwezindleko uma kuqhathaniswa nama-alloys asekelwe ku-nickel.

Izinselelo Nemikhawulo

Naphezu kwamandla ayo, insimbi ye-manganese inezinselele ezithile eziphawulekayo. Inkinga eyodwa enkulu amandla ayo okuqala aphansi esivuno, ngokuvamile aqala phakathi kuka-200 MPa no-300 MPa. Nakuba impahla ingaba lukhuni ngaphansi komthelela, lawa mandla esivuno esiphansi angayenza ingasebenzi kahle ezinhlelweni ezinemithwalo emaphakathi noma emile.

Omunye umkhawulo uhilela i-ductility yayo. Ukuthuthukisa amandla ensimbi ye-manganese ngokucubungula njalokunciphisa ukuguquguquka kwayo, okudala ukuhwebelana phakathi kokuqina nokuqina. Ukwengeza, izigaba ezithile, njengesigaba se-hexagonal close-packed (HCP), zingakheka ngesikhathi sokucubungula. Lezi zigaba zandisa ingozi yokuphuka, okwenza kube nzima nakakhulu ukusetshenziswa kwayo kwezinye izimboni.

Izinto Eziqhudelana Nezinto Ezintsha

Ukuthuthukiswa kwezinto ezintsha kanye nobuchwepheshe sethule ukuncintisana kwensimbi ye-manganese. Intuthuko ocwaningweni lwe-metallurgical iholele ekudalweni kwama-alloys asebenza kahle kakhulu nezinhlanganisela ezibekela inselele ukubusa kwayo.

- Ukuqamba okusha kuma-alloys ensimbi, okufana nezinsimbi ze-manganese ezimaphakathi, kunikeza izakhiwo ezithuthukisiwe zemishini nokonga izindleko ngokunciphisa izakhi ze-alloying.

- Ubuchwepheshe bokukhiqiza okungeziwe buvumela ukukhiqizwa kwezinto ezingokwezifiso ezinezakhiwo ezilungiselelwe izinhlelo zokusebenza ezithile.

- Izimboni ezifana nezezimoto kanye ne-aerospace zishayela isidingo sezinto ezingasindi, eziqine kakhulu, ezivame ukudinga ukuhlolwa kwe-metallurgical okuthuthukisiwe ukuze kuqinisekiswe ukuphepha nokuhambisana.

Nakuba insimbi ye-manganese isalokhu iyitshe lesisekelo ezimbonini ezisindayo, lezi zindlela ezintsha zigqamisa isidingo socwaningo oluqhubekayo ukuze kugcinwe ukubaluleka kwayo emakethe yokuncintisana.

I-Manganese Steel Namuhla Nezimo Zesikhathi esizayo

Ukusetshenziswa Kwezimboni Zanamuhla

Insimbi yeManganese iyaqhubeka nokudlalaindima ebalulekile ezimbonini zanamuhla. Ukuqina kwayo kanye nokumelana nomthelela kuyenza ibaluleke kakhulu emikhakheni efana neyokwakha, ezokuthutha, neyokukhiqiza. Eqinisweni, ukwenza insimbi kubala u-85% kuya ku-90% wesidingo se-manganese, okugqamisa ukubaluleka kwayo ekukhiqizeni ama-alloys aphezulu.

| Imboni/Uhlelo lokusebenza | Iphesenti Lesidingo SeManganese |

|---|---|

| Ukwenza insimbi | 85% kuya ku-90% |

| Ezokwakha, Imishini, Ezokuthutha | Ukusetshenziswa kokugcina okuhamba phambili |

| Ukusetshenziswa kwe-Nonmetallurgical | Umanyolo wezitshalo, ukudla kwezilwane, imibala yezitini |

Ngaphandle kokusetshenziswa kwendabuko, ama-manganese alloys azuza amandla embonini yezimoto. Izinto ezingasindi ezenziwe ngensimbi ye-manganese zisiza ukuthuthukisa ukusebenza kahle kukaphethiloli nokusebenza kokuphepha. Lolu shintsho luhambisana nesidingo esikhulayo sezixazululo zokonga ugesi kwezokuthutha.

Ukuguquguquka kwensimbi ye-Manganese kuqinisekisa ukuhambisana kwayo okuqhubekayo ezimbonini ezibeka phambili amandla, ukuqina, kanye nokuqamba okusha.

Ukusimama kanye Nemizamo Yokusebenzisa Kabusha

Ukusimama sekuyinto okugxilwe kuyo kakhulu embonini yensimbi, futhi insimbi ye-manganese iyafana. Ukugaywa kabusha kudlala indima ebalulekile ekwehliseni ukumoshwa kanye nokonga izinsiza. Amamethrikhi afana ne-End-of-Life Recycling Rate (EoL-RR) kanye ne-Recycling Process Efficiency Rate (RPER) ahlola ukuthi izinto ezilahliwe ziphinde zisetshenziswe ngempumelelo kangakanani.

| Inkomba | Isifinyezo | Incazelo emfushane |

|---|---|---|

| Isamba sesilinganiso sokufakwa kabusha kokugaya kabusha | I-TS–RIR | Ikala ingxenye yokokufaka kwesamba se-scrap ukuze kugaywe kabusha phezu kokufaka okuphelele kokubalulekile. |

| Izinga lokugaywa kabusha kokuphela kwempilo | EoL–RR | Ikala ingxenye yemvuthuluka endala egaywe kabusha phezu kwesamba senani elikhiqizwa minyaka yonke. |

| Izinga lokusebenza kahle kwenqubo yokugaya kabusha | RPER | Ikala ingxenye yesamba sesamba esigaywe kabusha esigaywe kabusha ngaphezu kokokufaka kwesamba se-scrap ukuze kugaywe kabusha. |

Imizamo yokugaywa kabusha kwensimbi ye-manganese ayinciphisi nje kuphela umthelela wendawo kodwa futhi ithuthukisa ukuzimela ekuhlinzekeni ngezinto ezibonakalayo. Lezi zinhlelo zihambisana nezinjongo zomhlaba wonke zentuthuko esimeme, ukuqinisekisa ukuthi izimboni zingahlangabezana nezidingo zesikhathi esizayo ngokuzibophezela.

Emerging Technologies and Applications

Ikusasa lensimbi ye-manganese libukeka lithembisa, ngenxa yentuthuko kwezobuchwepheshe kanye nezidingo zezimboni ezithuthukayo. ENingizimu Korea, imakethe yensimbi ye-manganese boron iyakhula ngenxa yokusetshenziswa kwayo emikhakheni yezimoto neyokwakha. Ukwenyuka kwezimoto zikagesi kunyuse nesidingo sezinto ezintsha, okuvula indlela yokusetshenziswa okusha kwensimbi ye-manganese.

- Insimbi yeManganese isekela ubuchwepheshe obuzinzile njengokwelashwa kwamanzi angcolile e-electrolytic manganese.

- Idlala indima ebalulekile ezinhlelweni zokugcina amandla kanye nezicelo ze-biomedical.

- Ukuhlanganiswa kanye nokutholwayo emkhakheni wensimbi kuqhuba ukwakhiwa okusha nokukhula kwemakethe.

Njengoba izimboni zihlola amathuba amasha,insimbi ye-manganese ihlala iyitshe legumbiyenqubekela phambili. Izakhiwo zayo ezinemisebenzi eminingi ziqinisekisa ukuthi izoqhubeka nokuzivumelanisa nezimo ezisafufusa kanye nobuchwepheshe.

Insimbi yeManganese ishiye uphawu olungacimeki kwezensimbi nezimboni kusukela yatholakala ngekhulu le-19. Umsebenzi wokuphayona kaSir Robert Hadfield wethula into engase ibe lukhuni ngaphansi komthelela, iguqule izicelo zezimayini, izitimela, nezokwakha. Ngokuhamba kwesikhathi, intuthuko efana nokwelashwa kokushisa nokulungiswa kwe-alloy kuye kwakhuphula izakhiwo zayo zemishini, iqinisekisa ukuhambisana kwayo okuqhubekayo ezindaweni ezinomthelela omkhulu.

Izinsimbi ze-manganese ezimaphakathi, ezinokwakheka okusuka ku-3% ukuya ku-10% we-manganese, zibonisa izakhiwo ezincane ezihlukile namandla angavamile. Izindlela zokukhiqiza ezifana ne-Deforming and Partitioning (D&P) ziphushe amandla esivuno kumazinga ahlaba umxhwele, okuwenza alungele izinhlelo zokusebenza eziqinisa ukucindezela.

Uma sibheka phambili, imboni ibhekene nezinselelo ezifana nokukhathazeka kwemvelo kanye nezindleko eziphezulu zokusebenza. Nokho, maningi amathuba. Isidingo esikhulayo sama-alloys asekelwe ku-manganese ekukhiqizeni insimbi nezisombululo zokugcina amandla avuselelekayo kuveza ukubaluleka kwawo kwamasu.

| Isigaba | Imininingwane |

|---|---|

| Abashayeli Abakhulu | - Ukwamukelwa okukhulayo kwezimoto zikagesi zamabhethri e-lithium-ion. |

| - Ukuthuthukiswa kwemisebenzi yengqalasizinda emhlabeni jikelele. | |

| Izithibelo Ezikhona | - Izingozi zezempilo ezihlobene nokuchayeka kwe-manganese. |

| Amathuba Avelayo | - Intuthuko kubuchwepheshe bezimayini kanye nezinqubo ezisimeme. |

Ikhono lensimbi ye-Manganese lokuzivumelanisa nobuchwepheshe obusafufusa liqinisekisa indawo yayo esikhathini esizayo semboni. Kusukela ezinhlelweni zokugcinwa kwamandla kuya ku-metallurgy ethuthukisiwe, ukuguquguquka kwayo kuyaqhubeka nokugqugquzela ukusungula nokusimama.

FAQ

Yini eyenza insimbi ye-manganese ikhetheke kangaka?

Insimbi yeManganese ihlukilengoba iqina ngaphansi komthelela. Lesi sakhiwo, esibizwa ngokuthi ukuqina komsebenzi, sikwenza kube nzima uma sisetshenziswa kakhulu. Ilungele amathuluzi anethonya eliphezulu nemishini ebhekana nokuguga okungaguquki.

Ingabe insimbi ye-manganese ingagaywa kabusha?

Yebo! Ukugaywa kabusha kwensimbi ye-manganese kusiza ukunciphisa ukumosha nokulondoloza izinsiza. Izimboni zisebenzisa kabusha izinto ezilahliwe ukuze zenze imikhiqizo emisha, zikwenze kube ukukhetha okuvumelana nemvelo kokukhiqiza okuzinzile.

Iphi insimbi ye-manganese evame ukusetshenziswa?

Uzothola insimbi ye-manganese ezintweni zezimayini, amathrekhi wesitimela, namathuluzi okwakha. Ukuqina kwayo kanye nokumelana nomthelela kuyenza ilungele izindawo lapho izinto ezisetshenziswayo zibhekana nengcindezi enkulu.

Ingabe insimbi ye-manganese ingcono kunezinye izinto?

Ezimweni ezinomthelela ophezulu, insimbi ye-manganese idlula izinto eziningi. Iqinile futhi ihlala isikhathi eside. Kodwa-ke, ayisebenzi kahle emithwalweni emile noma izinhlelo zokusebenza ezingasindi, lapho amanye ama-alloys angase asebenze kangcono.

Insimbi ye-manganese isiza kanjani izimboni ukuthi zonge imali?

Ukumelana kwayo nokugqokakunciphisa isidingo sokushintshwa njalo. Izimboni ezisebenzisa insimbi ye-manganese zichitha imali encane ekunakekeleni nasekusebenzeni isikhathi sokuphumula, zikhuphula ukusebenza kahle kanye nokunciphisa izindleko.

Isikhathi sokuthumela: Jun-09-2025