Izinto zokusakazaubumba imikhiqizo njenge-aUmshini Wokugaya Emhlathini or I-Gyratory Crusher. Basiza ukudala yonke into kusukaIzingxenye ze-Cone Crusherkwe aI-Manganese Steel Hammer. Ukukhetha okufanele kubalulekile. Bheka leli thebula elivela kumsunguli ophezulu waseYurophu:

| I-Cast Iron Output Yonyaka | amathani angama-23,000 |

| Isilinganiso Sesici | 5–7% |

Isayensi yezinto ezibonakalayo ihlanganisa izinsimbi, i-ceramics, ama-polymers, nezinhlanganisela. Ukwazi okubalulekile kokulingisa kusiza onjiniyela bakhulise ikhwalithi futhi banqamule imfucuza.

Okuthathwayo Okubalulekile

- Ukukhetha izinto zokuphonsa ezifanele, njengensimbi, insimbi,i-aluminium, noma amapulasitiki, athinta ngokuqondile ikhwalithi yomkhiqizo, izindleko, nokusebenza.

- Izinto ezisansimbi ziqukethe i-ayoni futhi ziqinile kodwa zingagqwala, kuyilapho izinto ezingenayo insimbi njenge-aluminium nethusi zimelana nokugqwala futhi zilula.

- Amapulastiki nezitsha zobumba zinikeza izinzuzo eziyingqayizivele ezifana nokumelana nokugqwala nokubekezelela ukushisa, okuzenza zilungele ukusetshenziswa okukhethekile.

Izinhlobo Eziyinhloko Zezinto Zokusakaza

Insimbi Yokuphonsa: Insimbi nensimbi

Izinto zokuphonsa ezisansimbi zihlanganisa insimbi nensimbi. Lezi zinsimbi ziqukethe insimbi njengento yazo eyinhloko. Badlala indima enkulu emishinini esindayo nasekwakhiweni. Insimbi nensimbi kunezindawo ezihlukene. Ithebula elingezansi libonisa ukuthi ziqhathanisa kanjani:

| Isakhiwo / Isici | Insimbi | Insimbi (kufaka phakathi izinsimbi ezithambile nezikhabhoni) |

|---|---|---|

| Okuqukethwe kwekhabhoni | 2–4.5% | 0.16–2.1% |

| Izakhiwo Zemishini | Amandla aphezulu okucindezela; brittle | I-Ductile; amandla okuqina ayahluka |

| Ukumelana Nokugqwala | Kungcono emoyeni ongcolile | Igqwala ngokushesha |

| Ukusebenziseka kalula | Kulula (insimbi empunga); insimbi eqinile (insimbi emhlophe) | Kuhle, kuyahlukahluka ngohlobo |

| Izinhlelo zokusebenza | Amabhulokhi enjini, ama-rotor amabhuleki | Amagiya, iziphethu, izingxenye zezimoto |

Izinto zokusansimbi zisebenza kahle kumabhulokhi enjini nasezindlini zokumpompa.Izinto zokusansimbi zensimbiilingana namagiya, izipringi, nezingxenye zemoto eziningi. Uhlobo ngalunye luletha amandla alo etafuleni.

Izinto Zokusakaza Ezingezona Insimbi: I-Aluminium, Ithusi, iMagnesium, iZinc

Izinto zokuphonsa ezingenayo insimbi azinayo insimbi njengento eyinhloko. I-Aluminium, ithusi, i-magnesium, ne-zinc ingeyaleli qembu. Lezi zinsimbi zilula kunensimbi nensimbi. I-aluminium casting impahla idumile ezingxenyeni zemoto namafreyimu endiza. I-Copper casting material isebenza ezingxenyeni zikagesi ngoba iqhuba kahle ugesi. I-Magnesium ne-zinc casting materials isiza ukwenza izingxenye ezingasindi zama-electronics namathuluzi. Izinsimbi ezingenayo insimbi zimelana nokugqwala futhi zinikeza amandla amahle ngesisindo sazo.

Ezinye Izinto Zokuphonsa: Ipulasitiki namaCeramics

Ezinye izinto zokulingisa azizona neze izinsimbi. Ipulasitiki kanye ne-ceramics inikeza izinzuzo eziyingqayizivele. Amapulasitiki angakha izimo eziyinkimbinkimbi futhi amelane nokugqwala. I-Ceramics ime ekushiseni okuphezulu. Abantu basendulo babesebenzisa i-ceramic casting material ukuze bancibilikise ithusi. I-ceramics yesimanje, njenge-nano-zirconia, ibonisa ukusebenza okungcono nakakhulu. Zinamandla aphezulu okugoba, ukuqina, nokumelana nokuklwebheka. Lezi zitsha zobumba zisiza ukwenza izingxenye ezincane, eziqinile zamafoni namawashi.

Amapulastiki nezitsha zobumba zivula iminyango emisha yezinto zokusakaza, ikakhulukazi lapho ukumelana nokushisa noma izimo ezikhethekile zibalulekile.

Izakhiwo kanye nokusetshenziswa kwezinhlobo zezinto zokulingisa

Insimbi Yokuphonsa Izinto

Insimbi yokuphonsa igqama ngamandla ayo ekucindezelweni. Abantu bavame ukuyisebenzisela amakholomu, amabhulokhi enjini, nemishini esindayo. I-Grey cast iron iqukethe ama-carbon flakes, akwenza kube lula ukuwenza umshini kodwa aphinde abe brittle. I-White cast iron, enekhabhoni njenge-iron carbide, inikeza amandla angcono okuqina kanye nokusebenziseka kalula.

- Amandla:

- Iphatha kahle imithwalo esindayo.

- Kuhle ezingxenyeni ezingagobi kakhulu.

- Ubuthakathaka:

- I-brittle futhi ingaphuka ngaphansi kwengcindezi.

- Ijwayele ukugqwala, ikakhulukazi ezindaweni ezinomswakama.

Ukwengeza izinto ezifana ne-silicon, i-nickel, noma i-chromium kungakhuphula ukumelana nokugqwala nokuqina. Ukudweba okuvamile nokuhlola kusiza ukuvimbela ukugqwala nokugcina insimbi isesimweni esihle.

Ukuhlola kubonisa ukuthi isihlabathi esisetshenziswa ekubumbeni insimbi singakwazi ukumelana nokushisa okuphezulu, kodwa ukwakheka kwayo kuncike kusayizi nokuma kwesihlabathi okusanhlamvu. Lokhu kuthinta indlela umkhiqizo wokugcina ozwakala ngayo ubushelelezi noma obumahhadla.

Izinto Zokusakaza Zensimbi

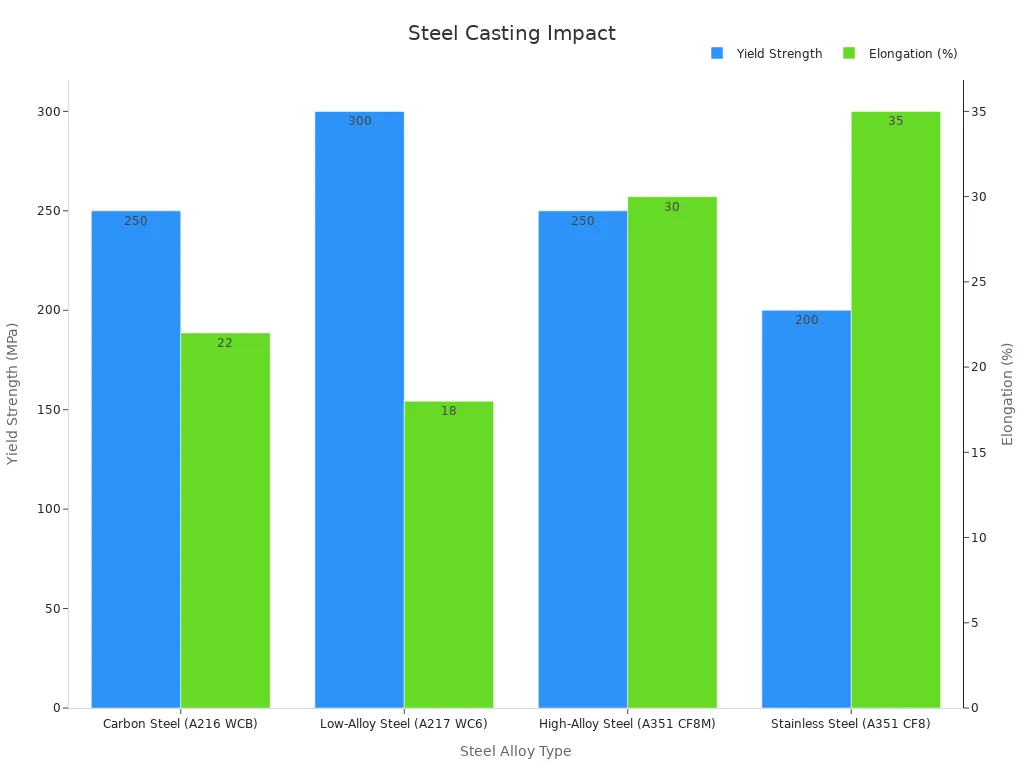

Izinto zokuphonsa zensimbi ziletha inhlanganisela yamandla, i-ductility, nokuqina. Abantu bakhetha insimbi yamagiya, izipringi, nezingxenye zezimoto ngoba ikwazi ukumelana nakho kokubili ukushuba nokucindezelwa. Izakhiwo zensimbi zishintsha ngama-alloys ahlukene kanye nokwelashwa.

| Uhlobo lwe-Steel Alloy | I-Yield Strength (MPa) | Amandla Okuqina (MPa) | Ubude (%) | Ukumelana Nokugqwala |

|---|---|---|---|---|

| I-Carbon Steel (A216 WCB) | 250 | 450-650 | 22 | Impofu |

| Insimbi ye-Low-Alloy (A217 WC6) | 300 | 550-750 | 18 | Kuhle |

| I-High-Alloy Steel (A351 CF8M) | 250 | 500-700 | 30 | Kuhle kakhulu |

| Insimbi Engagqwali (A351 CF8) | 200 | 450-650 | 35 | Kuhle kakhulu |

Ukusebenza kwensimbi kuncike ekutheni yenziwa kanjani. Ukupholisa okusheshayo kudala izinhlamvu ezincane, okwenza insimbi ibe namandla. Ukwelashwa kokushisa nezindlela zokuphonsa ngokucophelela kungathuthukisa ukuqina futhi kunciphise amaphutha njengama-pores.

I-Aluminium Casting Material

I-aluminium casting impahla idumile ngesisindo sayo esilula nokuguquguquka. Kuvamile ezingxenyeni zemoto, amafreyimu endiza, nezinto zikagesi. I-Aluminium igqama ngesilinganiso sayo esihle samandla nesisindo kanye nokumelana okuhle nokugqwala.

| Isakhiwo/Isici | I-Aluminium yokusakaza | Cast Steel | Insimbi Empunga |

|---|---|---|---|

| Ukuminyana | 2.7 g/cm³ | 7.7–7.85 g/cm³ | 7.1–7.3 g/cm³ |

| Amandla Okuqina | 100–400 MPa (kufika ku-710 MPa kwamanye ama-alloys) | 340–1800 MPa | 150-400 MPa |

| I-Melting Point | 570–655°C | 1450–1520°C | 1150–1250°C |

| I-Thermal Conductivity | 120–180 W/m·K | Kuphakathi | ~46 W/m·K |

| I-Electric Conductivity | Kuhle | Impofu | Impofu |

| Ukusebenziseka kalula | Kulula | Kuphakathi | Kuhle kodwa brittle |

| Ukumelana Nokugqwala | Kuhle kakhulu | Kuphakathi | Impofu |

| I-Vibration Damping | Kuphakathi | Kuhle | Kuhle kakhulu |

| Izindleko | Iphansi yokukhiqiza ngobuningi | Phezulu | Kuphakathi |

- Izinzuzo:

- Yenza izimo eziyinkimbinkimbi ngokunemba okuphezulu.

- Yonga amandla ngenxa yephoyinti elincibilikayo eliphansi.

- Imelana nokugqwala, ngakho ihlala isikhathi eside ngaphandle.

- Ilungele ukukhiqizwa kwevolumu ephezulu.

- Imikhawulo:

- Ayinamandla njengensimbi.

- Kungaba brittle kwamanye ama-alloys.

- Idinga ukulawula ngokucophelela ukugwema amaphutha afana ne-porosity.

Ukuhlaziywa kwezibalo kubonisa ukuthi ikhwalithi yokuncibilika kwe-aluminium kanye nokuba khona kokukhubazeka kunomthelela omkhulu emandleni nasekuqineni. Onjiniyela basebenzisa izivivinyo ezikhethekile nesofthiwe ukuze bahlole futhi bathuthukise ikhwalithi yokusakaza.

I-Copper Casting Material

I-Copper casting impahla yaziwa kakhulu ngokusebenza kwayo kagesi kanye ne-thermal. Abantu basebenzisa ithusi ezingxenyeni zikagesi, amapayipi amanzi, nezinto zokuhlobisa. Ama-alloys ethusi, njengethusi nethusi, anikeza amandla engeziwe nokumelana nokugqwala okungcono.

| Isampula ye-alloy | I-Electrical Conductivity (% IACS) | Ubulukhuni obuncane (Vickers) | I-Yield Strength (MPa) |

|---|---|---|---|

| I-EML-200 | 80% | Iqhathaniswa ne-EMI-10 | 614 ± 35 |

| EMI-10 | 60% | Iqhathaniswa ne-EML-200 | 625 ± 17 |

Ukwelashwa okufana nokupholisa okujulile kungakhuphula ukusebenza ngaphandle kokulahlekelwa amandla. Ukwengeza izakhi ezifana ne-zinc noma ithini kungathuthukisa ukumelana nokugqokwa nokuqina. I-Copper castings isebenza kahle ezindaweni ezinzima ngoba imelana nokugqwala, ikakhulukazi uma ihlanganiswe nezinye izinsimbi.

I-Magnesium Casting Material

I-Magnesium casting material ilula kunazo zonke izinsimbi zesakhiwo. Ilungele izingxenye ezidinga ukuqina kodwa zingabi nzima, njengezimoto, izindiza, nezinto zikagesi. Ama-alloys e-Magnesium anesilinganiso esiphezulu samandla nesisindo futhi kulula ukuwenza ngomshini.

- Izici Eziyinhloko:

- Ilula kakhulu, esiza ukonga uphethiloli ezimotweni.

- Ukuqina okuhle nokuqina.

- Amandla athile aphezulu, ikakhulukazi kuma-alloys asakazwayo.

Ukuhlolwa kokuhlola kubonisa ukuthi ukwengeza izimbobo noma izimo ezikhethekile kungenza i-magnesium ibe lula ngaphandle kokulahlekelwa amandla amaningi. Kodwa-ke, i-magnesium ingagqwala kalula, ngakho-ke i-coatings noma izakhi ze-alloying zivame ukusetshenziselwa ukuyivikela.

Zinc Casting Material

I-Zinc casting material ivame ukusetshenziselwa izingxenye ezincane ezinemininingwane. Kulula ukuyisakaza futhi igcwalisa isikhunta kahle, iyenze ibe yinhle kumagiya, amathoyizi, nehardware. Ama-alloys e-Zinc anikeza amandla amahle kanye nokuqina kwesisindo sawo.

- Izinzuzo:

- Kuhle kakhulu ekwenzeni izimo eziyinkimbinkimbi.

- Ukumelana nokugqwala okuhle.

- Indawo encibilikayo ephansi yonga amandla ngesikhathi sokusakaza.

- Izinselelo:

- Ayiqinile njengensimbi noma i-aluminium.

- Kungaba brittle ngokuhamba kwesikhathi, ikakhulukazi ezimweni ezibandayo.

I-Zinc casting ijwayelekile ezimbonini zezimoto nezama-elekthronikhi ngoba ihlanganisa ukunemba nokusebenza kahle kwezindleko.

I-Plastic Casting Material

Izinto zokuphonsa zepulasitiki zivula izinketho eziningi zokuklama. Ayisindi, imelana nokugqwala, futhi ingathatha cishe noma yikuphi ukuma. Abantu basebenzisa ukusakaza kwepulasitiki kumishini yezokwelapha, ezimpahleni zabathengi, nasezintweni zezimoto.

- Izici zikaMechanical:

- Amandla, ukuqina, nokuqina kuncike ohlotsheni lwepulasitiki nokuthi lwenziwa kanjani.

- Ukwengeza imicu efana nekhabhoni noma ingilazi kungenza amapulasitiki aqine kakhulu.

| Impahla / Impahla | I-Woodcast® | Izinto Zokusakaza Zokwenziwa | I-Plaster yaseParis (PoP) |

|---|---|---|---|

| Amandla Wokucindezela | Phezulu | Phansi | Brittle |

| Amandla Okuqina | Phansi | Phezulu | Brittle |

| Amandla e-Flexural (MPa) | 14.24 | 12.93–18.96 | N/A |

| Ukumelana Namanzi | Kuhle | Iyahlukahluka | Impofu |

Ama-castings epulasitiki angakwazi ukuphatha amanzi nokushisa kahle, kuye ngezinto ezibonakalayo. Ezinye azinabo ubuthi futhi ziphephile ukusetshenziswa kwezokwelapha. Ezinye zingase zibe namakhemikhali adinga ukuphathwa ngokucophelela.

I-Ceramic Casting Material

I-Ceramic casting material igqama ngekhono layo lokusingatha amazinga okushisa aphezulu. I-Ceramics iqinile, ayigugi, futhi ayigqwali. Abantu bazisebenzisa ku-electronics, i-aerospace, ngisho nobucwebe.

- Izici Zokushisa:

- Iyakwazi ukumelana namazinga okushisa afinyelela ku-1300°C.

- Kuhle kakhulu ku-insulation kanye nezihlangu zokushisa.

- Ukuqina:

- Imicu ye-ceramic eguquguqukayo ingasetshenziswa ekufakweni kabusha okusebenziseka kalula kwemikhumbi-mkhathi.

- I-ceramics ethuthukisiwe ihlanganisa amandla aphezulu ne-conductivity ephansi yokushisa.

Abacwaningi benze izinto ezintsha zobumba eziqinile futhi eziguquguqukayo, ezizenza zibe zilungele izindawo eziyingozi kakhulu njengesikhala noma ukukhiqizwa kobuchwepheshe obuphezulu.

Izinto zokubunjwa ze-Ceramic zigcina ukuma kwazo namandla ngisho nangaphansi kokushisa okukhulu, okwenza zibe yigugu ezinhlelweni eziningi zesimanje.

Ukukhetha okubalulekile okulingisayo kubumba ikhwalithi yomkhiqizo, izindleko, nokusebenza. Onjiniyela baqhathanisa izindlela zokusakaza nezakhiwo besebenzisa amathebula nezifundo zezindaba zomhlaba wangempela ukuze bafanise into ngayinye nokusetshenziswa kwayo okungcono kakhulu. Ukwazi le mininingwane kusiza amaqembu aklame izingxenye ezingcono, onge imali, futhi agweme amaphutha abizayo.

FAQ

Uyini umehluko omkhulu phakathi kwezinto zokuphonsa eziyinsimbi nezingezona ayoni?

Izinto ezisansimbi zinensimbi. Izinto ezingezona insimbi azikwenzi. Izinhlobo ezisansimbi zivame ukuba nesisindo esiningi futhi zigqwale ngokushesha. Izinhlobo ezingezona insimbi zimelana nokugqwala futhi zizizwe zilula.

Kungani onjiniyela bekhetha i-aluminium ukuze bayikhiphe?

I-Aluminium inesisindo esingaphansi kwensimbi. Imelana nokugqwala futhi ibumbe kalula. Onjiniyela bayayithanda izingxenye zemoto, amafreyimu endiza, nezinto zikagesi.

Ingabe amapulasitiki nezitsha zobumba zingakwazi ukumelana nokushisa okuphezulu?

I-Ceramics ibamba ukushisa okuphezulu kakhulu. Ipulasitiki ivamise ukuncibilika emazingeni okushisa aphansi. Onjiniyela bakhetha izinto zobumba zikahhavini noma izinjini, kuyilapho amapulasitiki elingana nemisebenzi epholile.

Isikhathi sokuthumela: Jun-17-2025