Izakhiwo zokuphakelayo zidlala indima ebalulekile ekunqumeni impilo yesevisi yeizingxenye zomhlathi we-crusher. Ama-opharetha aphethe ubulukhuni, ukuhuga, usayizi wezinhlayiyana, kanye nomswakama banganweba isikhathi sempiloinsimbi ye-manganese izingxenye zokugqoka ze-jaw crusher.

- Ubulukhuni obuphezulu kanye nokuhuga kwandisa amazinga okushintsha nokusetshenziswa kwamandla.

- Umswakama nokunamathela kungabangela ukuxhuma, okuholela ekunakekeleni okwengeziwe.

- Usayizi wokuphakelayo ongaguquki usiza ukuvimbela isikhathi sokuphumula futhi uthuthukisa ukusebenza kwe-crusher.

Ukukhetha okulungileumshini wokugaya umhlathifuthiizingxenye ze-crusherkwehlisa izindleko futhi kukhuphule ukusebenza kahle.

Okuthathwayo Okubalulekile

- Ukuqina nokugqamuka kwezinto eziphakelayo kukhulisa kakhulu ukuguga ezingxenyeni ze-crusher emihlathini, ngakho o-opharetha kufanele balungise izilungiselelo futhi bakhethe izinto eziqinile zokunweba ingxenye yempilo.

- Ukulawula usayizi wokuphakelayo nokukhipha amatshe amakhulu noma izinhlawulo kusiza ukuvimbela ukuguga okungalingani nokuvinjwa, kube ngconoukusebenza kahle kwe-crusherkanye nokunciphisa isondlo.

- Umswakama nezinto ezinamathelayo zibangela ukuvala kanye nengcindezi eyengeziwe ezingxenyeni ze-crusher, ngakho-ke ukuphatha umswakama ngokomisa nokuhlola kugcina ama-crushers asebenza kahle.

- Ukukhetha ilungeloizinto zepuleti lomhlathikanye nemiklamo esekelwe ezimpahleni zokuphakelayo ingaphindaphinda impilo yokugqoka futhi inciphise isikhathi sokuphumula.

- Ukuhlola okuvamile, ukunakekelwa okufanele, nokuqeqeshwa komsebenzisi kubalulekile ukuze uthole ukuguga kusenesikhathi nokugcina ama-crusher esebenza kahle isikhathi eside.

Impahla Yesiphakeli Esibalulekile kanye Nomshini Wokugqokwa Kwemihlathi

Ukuqina Kwezinto Zokuphakelayo

Ukuqina kugqama njengenye yezinto ezibaluleke kakhulu ezithinta ukugqokwa kwe-crusher yomhlathi. Amatshe aqinile, njenge-granite noma i-basalt, adinga amandla engeziwe ukuze aphule. La mandla engeziwe akhulisa ingcindezi kumapuleti emihlathi nama-liner. Lapho ama-opharetha efaka izinto eziqinile emshinini wokuchoboza imihlathi, amapuleti abhekana nokuguga okuthe xaxa kokusika nokuqopha. Ucwaningo lubonisa ukuthi amatshe anamandla acindezelayo aphezulu kanye nokuqina kokuphuka abangela ukuguga okusheshayo. Ama-opharetha avame ukuqaphela ukuthi ukuphela kokukhululwa kwemihlathi kuyaguga kuqala lapho kucutshungulwa izinhlayiya ezincane, eziqinile. Ukulungisa izilungiselelo ze-crusher ngokusekelwe kukuqina kokuphakelayo kungasiza ekunciphiseni ukuguga nokwelula ingxenye yempilo.

Abrasiveness and Mineral Composition

I-Abrasiveness kanye nokwakheka kwamaminerali nakho kudlala indima enkulu emaphethini okugqoka. Amaminerali afana ne-quartzite ne-granite ayaluma kakhulu. Lawa amaminerali agaya ngokumelene namapuleti emihlathi, okubangela ukuwohloka ngokushesha kwendawo. Uma ukudla kuqukethe iphesenti eliphezulu lamaminerali abrasive, standardama-manganese steel linersingase iguge ngokushesha. Ukukhetha okubalulekile kwelayini, okufana nensimbi ene-chrome ephezulu noma ama-alloys ahlanganisiwe, kungasiza ukumelana nalolu hlobo lokugqoka. Ama-opharetha kufanele futhi abheke ukungcola kokuphakelayo, njengoba i-tramp iron noma amatshe amakhulu kakhulu angabangela ukuqhekeka konqenqema nokuqhekeka.

Ithiphu: Ukufanisa impahla ye-liner nokwakheka kwamaminerali kokuphakelayo kunganweba impilo yokuguga ngokufika izikhathi ezinhlanu futhi kunciphise izindleko zokuyilungisa.

Usayizi Wezinhlayiya Nosayizi Wokusabalalisa

Usayizi wezinhlayiya kanye nokusatshalaliswa kwawo kuthinta ngqo ukuthi amapuleti emihlathi adinga ukushintshwa kaningi kangakanani. Uma okuphakelayo kuqukethe amadwala amaningi amakhulu, izindawo ezithile zemihlathi zithola imithelela ephindaphindiwe. Lokhu kuholela ekugqokeni okungalingani kanye nokushintshwa okuvamile. Izinhlawulo ezeqile kokuphakelayo zingabangela ukuvinjelwa, okubuye kunciphise isikhathi sokuphila samapuleti. Ukusatshalaliswa kosayizi wokuphakelayo okulawulwa kahle kukhuthaza ukuguga nokusebenza okuzinzile. Ama-opharetha aqapha futhi alungise usayizi wokuphakelayo anganciphisa izindleko zokusebenza futhi agcine umshini wokugaya imihlathi usebenza kahle.

Okuqukethwe Umswakama Nokunamathela

Okuqukethwe okunomswakama kokuphakelayo kudlala indima ebalulekile ekusebenzeni kwe-gaw crusher. Uma okuphakelayo kuqukethe umswakama ophezulu, ikakhulukazi uma kuhlanganiswe nezinhlawulo noma ubumba, kuvame ukuholela ezinseleleni zokusebenza. Izinto ezinamathelayo zivame ukunamathela endaweni engaphakathi kwe-crusher. Lokhu kunamathela kungabangela ukuvinjelwa, okwaziwa nangokuthi ukuvala, okuphazamisa inqubo yokuchoboza.

Ngokuvamile abahlinzeki bemishini bayaqaphela ukuthi izinto ezinhle ezimanzi, njengobumba, aziqhekeki kalula. Esikhundleni salokho, lezi zinto zihlangana zibe yinqwaba ngaphakathi kwegumbi lokuchoboza. Le nqubo, ebizwa ngokuthi “i-pancaking,” inyusa umthwalo enjini ye-crusher. Uma kuyekwa kungahloliwe, i-pancaking ingamisa i-crusher ngokuphelele. Nakuba umswakama ungakhulisi ngokuqondile izinga lokuguga lamapuleti emihlathi noma ama-liner, ukuvala okuwumphumela nokugcwala kwezimoto kunganciphisa ukusebenza kahle futhi kungaholela ekugugeni ngokushesha ngokuhamba kwesikhathi.

Izinyathelo ezimbalwa ezisebenzayo zisiza ukuphatha umswakama nokunamathela kokuphakelayo:

- Ukomisa kusengaphambili okuphakelayo ukuze unciphise umswakama ongaphansi kuka-5% kusiza ukuvimbela impahla ukuthi inganamatheli.

- Ukuhlola izinhlawulo ngaphambi kokuphakela i-crusher kunciphisa ingozi yokuvala.

- Ukufaka ama-anti-stick liners, njengezindawo ezimbozwe i-Teflon kuma-chute okuphakelayo, kunciphisa ukunamathela kokubalulekile.

- Ukusebenzisa izindonga ze-baffle ukuqondisa kabusha ukugeleza kwempahla, ikakhulukazi ngeziphakeli ezidlidlizayo, kungaqhubeka nokunciphisa ukuvala.

Qaphela: Ama-opharetha aqapha amazinga womswakamo futhi alungise izinqubo zawo angagcina ukusebenza kahle kwe-crusher futhi andise impilo yezingxenye ezigugile.

Ukuphatha umswakama nokunamathela kokuphakelayo akugcini nje ngokuthuthukisa ukwethembeka kwe-crusher kodwa futhi kwehlisa izindleko zokuyilungisa. Ngokuthatha lezi zinyathelo, ama-opharetha aqinisekisa ukuthi imishini yokugaya imihlathi isebenza kahle, ngisho nalapho icubungula izinto eziyinselele.

Umthelela Wempahla Yokuphakelayo Ezingxenyeni Zomshini We-Jaw Crusher

Ukuqina Kwemiphumela ku-Jaw Plate kanye ne-Liner Wear

Ukuqina kwezinto eziphakelayo kuthinta ngqo izinga lokugqoka lamapuleti emihlathi nama-liner. Amatshe aqinile, njenge-granite noma i-quartzite, adinga amandla engeziwe ukuze aphule. La mandla akhuphukayo aholela ekucindezelekeni okuphezulu ezindaweni ezithintana ne-crusher yomhlathi. Ngokuhamba kwesikhathi, imithelela ephindaphindayo evela ezintweni eziqinile idala ukuguga kokusika kweshizolo, okubonakala njengokuklwebheka okujulile, imifantu, kanye nemigodi kumacwecwe emihlathi. Ama-opharetha avame ukubona ukuthi izindawo ezichotshozwayo zithola ukuguga okunzima kakhulu, ikakhulukazi lapho kucutshungulwa ama-ore anobunzima obukhulu.

Ukukhathala kuyakhula futhi lapho amapuleti emihlathi ebhekana nokucindezelwa okuphindaphindiwe kanye nemithwalo yethonya. Imifantu yakheka futhi isakazeke, ekugcineni ibangele ukuphuka okuphukayo. Indawo yokudla, lapho amatshe aqala ukungena khona ku-crusher, isengozini kakhulu kulolu hlobo lomonakalo.Amapuleti emihlathi ensimbi ye-manganese ephezuluzingamelana nokunye kwalokhu kugqoka ngoba zisebenza kanzima ngesikhathi sokusebenza, kodwa ngisho nalezi zinto ezisetshenziswayo zinemikhawulo lapho zivezwe kokuphakelayo okunzima kakhulu.

Ithiphu: Ukuqapha njalo ubulukhuni bezinto ezingenayo kusiza opharetha ukuthi balungise izilungiselelo ze-crusher futhi bakhethe izinto ezisetshenziswayo zamalayini, kunciphisa isikhathi sokuphumula esingalindelekile.

Amaminerali Abrasive and Surface Degradation

Amaminerali abrasive kusiphakeli, njenge-quartz noma i-silica, asheshisa ukuwohloka kwendawoizingxenye zomhlathi we-crusher. Ukuhlolwa kokuhuzuka kwaselabhorethri, okuhlanganisa nokuhlolwa kokuhuzuka, kubonisa ukuhlobana okuqinile namaphethini okugqoka omhlaba wangempela. Lokhu kuhlola kwembula ukuthi amaminerali abrasive abangela ukulima okuncane, ukusikwa okuncane, kanye nokuqhekeka okuncane phezulu kwamapuleti emihlathi nama-liner. Njengoba izinhlayiya ezilumayo zishelela futhi zicindezela insimbi, zisusa izingcezu ezincane, okuholela ekulahlekeni kwevolumu kanye nezindawo ezilukhuni.

Ucwaningo lwasensimini luqinisekisa ukuthi ukuba khona kwamaminerali abrasive kwandisa izinga lokuguga. Izindlela zokugqoka eziyinhloko zihlanganisa:

- I-low-stress scratching abrasion:Kuvela lapho izinhlayiya zishelela phezu kwendawo ngaphandle kokucindezelwa okuningi.

- I-high-stress grinding abrasion:Kwenzeka lapho izinhlayiya ezincane zigaya ebusweni ngaphansi kwengcindezi.

- Ukukhishwa kwe-abrasion:Imiphumela evela ezinhlayiyeni ezinkulu, eziqinile ezithinta futhi ezicindezela amapuleti emihlathi.

Ithebula elingezansi lifingqa amaphethini okugqoka ajwayelekile kanye nezimbangela zawo:

| Uhlobo Lwephethini Yokugqoka | Incazelo | Imbangela/Izici Ezinomthelela | I-Jaw Plate Region | Phoqelela Izimpawu |

|---|---|---|---|---|

| I-Chisel Cutting Wear | Imihuzuko ejulile, imifantu, nemigodi | Umthelela ophindaphindiwe kanye nokukhishwa kwensimbi | Izindawo zokuchoboza (M, ML, L) | I-tangential ephakeme evamile, emaphakathi |

| Ukukhathala Gqoka | Imifantu nokuphuka okuphukayo | Umthelela ophindaphindiwe wesikhathi eside | Indawo yokudla (H) | High evamile, tangential ephansi |

| I-Abrasive Wear | Ukunwaya, ukugaya, ukuhuzuka | Usayizi wezinhlayiya, ubulukhuni, ukucindezela/ukugunda | Izindawo zokuchoboza (M, ML, L) | High evamile futhi tangential |

| I-Corrosion Wear | I-oxidation ngenxa yomswakama | Okuqukethwe umswakama okuphakelayo | Zonke izifunda | Ukugqokwa kwamakhemikhali |

Izinto ezibonakalayo ezinjengokuqina, ukuqina, kanye ne-microstructure nazo zinomthelela ekutheni izingxenye ze-crusher zomhlathi zimelana kanjani nokuguga. Izinguquko ku-liner geometry kusukela ekugqokeni zingathinta ukusebenza kwe-crusher, okwenza ukuhlolwa okuvamile kubalulekile.

Okuphakelayo Okukhulu Nethonya Lokuqukethwe Kwezinhlawulo

Ukusabalalisa usayizi wokuphakelayo kudlala indima enkulu ekugqokeni kwepuleti lemihlathi kanye nokugqokwa kwe-liner. Amatshe amakhulu kakhulu adala izindawo zokuthinta ezigxilile kumapuleti emihlathi. Le mithelela idala ukuguga okungalingani, nezindawo ezithile ziguga ngokushesha kunezinye. Uma izinhlayiya ezinkulu zingena ku-crusher, zingase futhi zibangele ukuhuzuka, okuholela emigodini ejulile kanye nemigodi.

Izinhlawulo ezeqile ekuphakeleni ziletha inselele ehlukile. Izinhlayiya ezinhle zingavala izikhala phakathi kwamadwala amakhulu, okwandisa ingozi yokuvinjelwa. Lokhu kuvinjelwa kuphoqa i-crusher ukuthi isebenze kanzima, iphakamisa izinga lokushisa kanye nengcindezi ezingxenyeni ezigugile. Ngokuhamba kwesikhathi, lokhu kungasheshisa ukuguga nokukhathala, ikakhulukazi uma izinhlawulo ziqukethe amaminerali abrasive.

Abasebenzisi bangaphatha lezi zingozi ngokuthi:

- Ukuhlola okuphakelayo ukuze kukhishwe izinhlawulo ezeqile ngaphambi kokuthi kungene ku-crusher.

- Ukulungisa ukulungiselelwa kohlangothi oluvaliwe (CSS) ukuze ulawule usayizi wezinto ezidlulayo.

- Ukwengamela ingxenye yamadwala amakhulu kakhulu nokulungisa ukuhlelwa kokuphakelayo.

Qaphela: Usayizi wokuphakelayo ongaguquki nokuqukethwe kwezinhlawulo ezilawulwayo kusiza ukugcina ngisho nokuguga kuwo wonke amapuleti emihlathi, ukuthuthukisa ukusebenza kahle nempilo yomshini wokugaya imihlathi.

Izindlela Zokugqoka Ezihlobene Nomswakama

Umswakama okokuphakelayo ungashintsha indlela izingxenye ze-crusher zomhlathi ezigqokwa ngayo ngesikhathi sokusebenza. Amanzi asebenza njengokubili okokugcoba kanye ne-catalyst yokuguga, kuye ngezimo ezingaphakathi kwe-crusher. Ama-opharetha ngokuvamile abona amaphethini okugqokwa ahlukene lapho elungisa izinto ezimanzi noma ezinamathelayo uma kuqhathaniswa namadwala omile, agelezayo ngokukhululekile.

Imithelela Eqondile Yomswakama Ekugqokeni:

- Amanzi angakha ifilimu elincanyana phakathi kwedwala nepuleti lomhlathi. Le filimu ngezinye izikhathi inciphisa ukungqubuzana, okunciphisa ukuguga kwe-abrasive.

- Ezimweni eziningi, umswakama uhlangana nezinhlayiya ezinhle nobumba. Le ngxube yenza unamathisele okunamathelayo onamathela ezitsheni zemihlathi nama-liner.

- Izinto ezinamathelayo zidala "i-pancaking," lapho izingqimba zezinhlawulo ezimanzi zakhelana endaweni ye-crusher. Lezi zingqimba zibamba izinhlayiya ezilumayo futhi zandise isenzo sokugaya ngokumelene nensimbi.

Imiphumela Engaqondile kanye Nokulimala Kwesibili:

- Umswakama ukhuthaza ukugqwala, ikakhulukazi uma kuhlanganiswa namaminerali asabela emanzini. Ukugqwala kwenza buthaka ingaphezulu lamapuleti emihlathi nama-liner, okuwenza abe sengcupheni yokuguga.

- Okumanzi okuphakelayo kuvame ukuholela ekuvinjweni. Lapho i-crusher igxuma, umshini kufanele usebenze kanzima ukuze usule isithiyo. La mandla engeziwe akhulisa ukucindezeleka ezingxenyeni ezigugile.

- Umswakama ophezulu ungabangela ukuguga okungalingani. Ezinye izindawo ze-jaw plate zingahlala zimbozwe izinto ezimanzi, kuyilapho ezinye zihlala obala. Lo mehluko uholela emaphethini okugqoka ama-patchy futhi unciphisa impilo yonke yezingxenye.

Qaphela:Abasebenzisi kufanele baqaphe kokubili umswakama kanye nohlobo lwenhlawulo ekuphakeleni. Izinto ezinobumba ezinobumba ezinamanzi amaningi zibangela ukuguga okukhulu kunesihlabathi esihlanzekile, esimanzi.

Izindlela Zokugqoka Ezihlobene Nomswakama Ezivamile:

| Indlela | Incazelo | Umphumela Ojwayelekile |

|---|---|---|

| Lubrication Effect | Ifilimu yamanzi inciphisa ukungqubuzana | Ukuguga okuhamba kancane |

| Pancaking/Build-up | Izinhlawulo ezinamathelayo zinamathela endaweni | Ukwenyuka kokugaya nokuguga |

| Izingubo Ezidlayo | Amanzi namaminerali kubangela ukusabela kwamakhemikhali | Ukugqwala, umgodi, ukulahleka komhlaba |

| Ingcindezi Ebangelwa Ukuvinjwa | Izinto ezimanzi zivala i-crusher, zikhuphule umthwalo | Ukukhathala nokuguga okusheshisiwe |

| Amaphethini Wokugqoka Angalingani | Umswakama uvikela ezinye izindawo, uveze ezinye | Ukugqokwa okunamavila, okungalindelekile |

Izinyathelo Ezisebenzayo Zokuphatha Ukugqokwa Okuhlobene Nomswakama:

- Ama-opharetha angakwazi ukubuka kuqala okuphakelayo ukuze asuse izinhlawulo nobumba oluningi ngaphambi kokuchotshozwa.

- Ukufaka izinzwa zomswakama kusiza ukulandelela izinguquko ezimeni zokuphakelayo.

- Ukusebenzisa ama-anti-stick liner noma ama-coatings kuma-chute nasezindaweni ze-crusher kunciphisa ukwakheka kwezinto.

- Ukuhlanza nokuhlola njalo kuvimbela umonakalo wesikhathi eside ekugqwaleni nasekuvinjweni.

Ithiphu:Ama-opharetha alawula umswakama nenhlawulo ekuphakeleni anganweba impilo yezingxenye ze-gaw crusher futhi anciphise isikhathi sokuphumula esingahlelelwe.

Izindlela zokugqoka ezihlobene nomswakama ziletha izinselelo eziyingqayizivele ekuchosheni izimboni. Ngokuqonda le miphumela, opharetha bangenza izinqumo ezingcono mayelana nokulungiswa kokuphakelayo, izilungiselelo ze-crusher, namashejuli okulungisa. Lolu lwazi luholela ekuphileni ingxenye ende kanye nokusebenza okuthembekile kwe-crusher.

Izifundo Zezimboni: Ukusebenza Komshini We-Jaw Crusher

Ukucutshungulwa Kwensimbi Eqinile Kakhulu

Imisebenzi yezimayini ivamise ukucubungula ama-ore ngobulukhuni obuphezulu kakhulu, njengegwadle noma i-quartzite. Lezi zinto zibeka ingcindezi enkulu ezingxenyeni ze-jaw crusher. Abasebenzi baqaphela ukuthi amapuleti emihlathi nama-liner aguga ngokushesha lapho echotshozwa la matshe aqinile. Amapuleti ensimbi e-manganese aphezulu asiza ukumelana nalokhu kugqoka ngoba aba nzima ngesikhathi sokusetshenziswa. Kwenye indawo yezimayini, opharetha bashintshele kumapuleti emihlathi angokwezifiso anephrofayili yamazinyo akhethekile. Lolu shintsho luthuthukise impilo yokuguga futhi lwehlise nenani lokuvala ukushintshwa. Ukuhlolwa okuvamile nokushintshwa ngesikhathi kwezingxenye ezigugile kwagcina i-crusher isebenza kahle. Ama-opharetha aphinde alungisa ukuhlelwa kokuphakelayo ukuze kugwenywe ukulayisha ngokweqile umshini.

I-Abrasive Aggregate Production

Ukukhiqizwa kwe-abrasive aggregate, njengokuchoboza i-basalt noma i-quartz-rich gravel, kudala indawo enzima yezingxenye zokuchotshozwa kwemihlathi. Ama-opharetha abona ukuhuzuka okuphezulu namandla omthelela kulezi zilungiselelo. Basebenzisa izinto ezisezingeni eliphezulu njengensimbi ye-manganese kumapuleti emihlathi ngenxa yezakhiwo zayo eziqinisa umsebenzi. Ukuma kanye nephrofayili yamazinyo yamapuleti kudlala indima ebalulekile ekulawuleni ukugqokwa. Ukwenza ngokwezifiso izingxenye zokugqokwa zeqoqo elithile kusiza ukusabalalisa okugqokwa ngokulinganayo futhi kukhuphule ukusebenza kahle. Abasebenzisi kulezi zindawo balandela amashejuli okulungisa aqinile. Bashintsha izingxenye ngesikhathi esifanele ukuvimbela ukwehluleka okungalindelekile.

- Izingxenye zokugqoka ze-jaw crusher zibhekana nokuhuzuka okukhulu namandla okuba nomthelela ekukhiqizweni kwe-abrasive aggregate.

- Izinto zekhwalithi ephezulu nemiklamo yangokwezifiso isiza ukumelana nokuguga futhi ithuthukise ukusebenza kahle.

- Isikhathi sokunakekela sibalulekile ekwenzeni impilo ibe ngcono.

Ithebula elingezansi lifingqa umehluko phakathi kwezinhlelo zokusebenza ezilimazayo nezingaqhumi kancane:

| Uhlobo Lohlelo Lokusebenza | Isilinganiso sokugqoka | Izinto Ezisetshenzisiwe | Izidingo Zesondlo |

|---|---|---|---|

| I-Abrasive Aggregate | Phezulu | Insimbi yeManganese | Okuvamile, Okuhleliwe |

| I-Abrasive Kancane | Phansi | Ama-Standard Alloys | Kancane Kakhulu |

Usayizi Wokuphakelayo Oguquguqukayo Ezinhlelweni Zokugaywa kabusha

Imisebenzi yokugaya kabusha ivamise ukubhekana nezinto eziphakelayo ezihluka ngosayizi nokuma. Lokhu kuhlukahluka kuthinta ukusebenza komshini wokugaya imihlathi kanye nokuphila isikhathi eside. Ngezinye izikhathi ama-opharetha abona ukuvaleka noma ukuma komshini lapho okuphakelayo kuqukethe izingcezu ezinkulu noma ezimise ngendlela eyinqaba. Ukugudluzwa komhlathi we-crusher kushintsha nobude besiphakeli, okuthinta ukusebenza kahle. Ngaphambi kokukhetha i-crusher yomhlathi ukuze igaywe kabusha, o-opharetha bahlaziya izici ezibonakalayo kanye nosayizi wokuphakelayo olindelekile. Ukusetshenziswa kwamandla nakho kuncike emandleni wento kanye nosayizi wokuvula we-crusher. Ukuchoboza ukhonkolo onamandla amakhulu kusebenzisa amandla amaningi kunezinto ezithambile. Osayizi abancane bokungena nabo bakhulisa ukusetshenziswa kwamandla. Lezi zici zibonisa ukuthi usayizi wokuphakelayo oguquguqukayo kanye nezakhiwo ezibonakalayo zidlala indima enkulu ekusebenzeni kwe-crusher kanye nempilo yengxenye yokugqoka.

Ama-opharetha aqapha usayizi wokuphakelayo futhi alungise izilungiselelo ze-crusher anganciphisa ukuguga futhi athuthukise ukusebenza kahle ekusetshenzisweni kabusha kwezinhlelo zokusebenza.

Ukwengamela kanye Nokunciphisa Ukugqokwa Komshini Wokugaya Emihlathini

Ukukhetha i-Jaw Plate kanye ne-Liner Materials

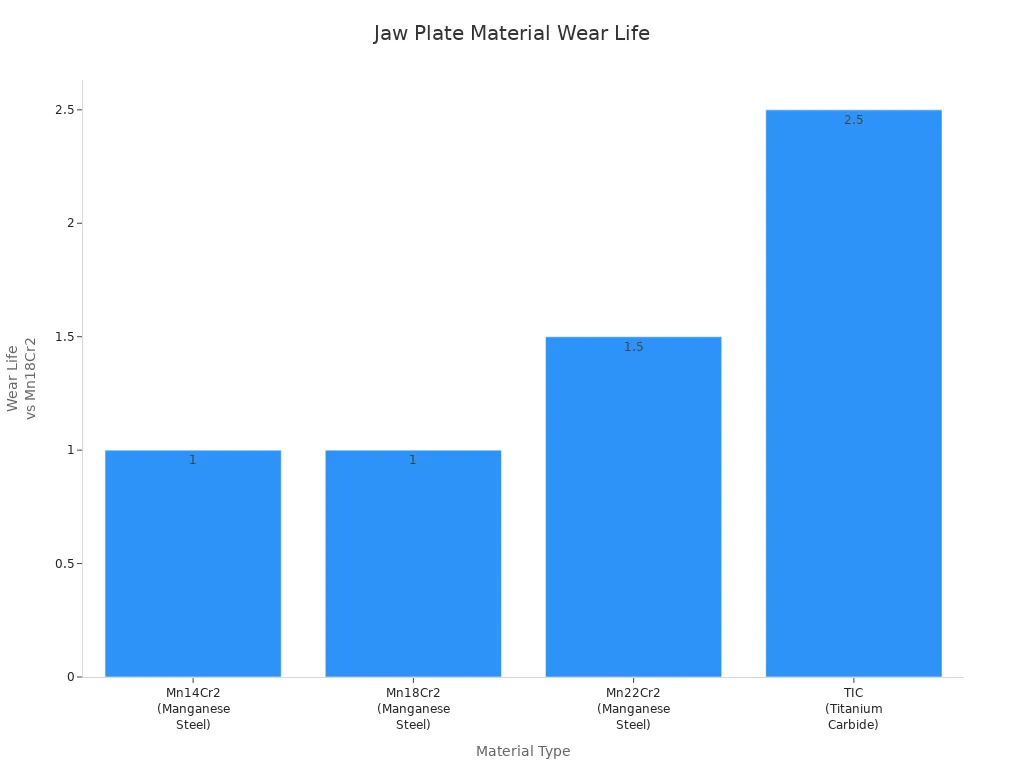

Ukukhetha okulungileipuleti lemihlathi kanye nezinto ze-linerkubalulekile ekunciphiseni ukuguga kwama-crushers embonini. Ama-opharetha ngokuvamile akhetha amamaki ensimbi ye-manganese ngokusekelwe ebukhuni kanye nokugqamuka kokuphakelayo. Ithebula elingezansi liqhathanisa izinto ezijwayelekile kanye nokusebenza kwazo:

| Uhlobo Lwezinto | Izakhiwo Eziyinhloko | Ukufaneleka Kwezinto Eziqinile/Eziqhumayo | I-Wear Life Iqhathaniswa ne-Mn18Cr2 |

|---|---|---|---|

| Mn14Cr2 | Amandla omthelela aphezulu, ukumelana nemihuzuko | Amatshe athambile noma angaqhumi | Isisekelo |

| Mn18Cr2 | Ukuqina okuhle kakhulu kokusebenza, ukumelana ne-abrasion | Amatshe amaphakathi ukuya kwanzima, angaqhumi | Isisekelo |

| Mn22Cr2 | Ukumelana ne-abrasion ephezulu, impilo ende yokugqoka | Amatshe aqinile futhi abrasive | Yinde kune-Mn18Cr2 |

| I-TIC Insets | Ukuqina okuphezulu kakhulu, ukumelana nomthelela | Izinto eziqinile futhi eziqhumayo | 1.5 ukuya ku-2.5 ubude obuphindwe ka-Mn18Cr2 |

Ama-opharetha acubungula izinto zokuphakelayo eziqinile noma ezilumayo ngokuvamile zikhetha i-Mn22Cr2 noma amapuleti afaka i-TIC ukuze aphile isikhathi eside futhi anciphise isikhathi sokuphumula.

Ilungisa Izilungiselelo Ze-Crusher kanye Namalungiselelo Okuphakelayo

Izilungiselelo ezifanele ze-crusher kanye namalungiselelo okuphakelayo kusiza ukunweba impilo yamapuleti emihlathi nama-liner. Abahlinzeki basebenzisa amasu amaningana:

- Ukuphakela emgqeni kuqondanisa okubalulekile nokuvuleka kwe-crusher, kunciphisa ukuvala nokuguga okungalingani.

- Ukuphakelwa kwe-Choke kugcina igumbi ligcwele okungenani ngama-80%, likhuthaza ukugqokwa komfaniswano kanye nokuchotshozwa okuphumelelayo.

- Ukuhlolwa kwangaphambili kususa izinhlawulo nezinto ezibonakalayo ezinkulu, kuvimbela ukuvinjwa nokuguga okungalingani.

- Okuphakelayo okunezinga elifanele kuqinisekisa ukusebenza kahle futhi kunciphisa ukuguga kwendawo.

- Ukukhawulela okuqukethwe kwensimbi kokuphakelayo kuvikela izingxenye emonakalweni.

Ukulungisa ukulungiselelwa kohlangothi oluvaliwe futhi kulawula i-nip angle nokusebenza kahle kokuchotshozwa. Ukuphakelwa okungaguquki kokuklinywa kanye nezilungiselelo ezifanele kugcina amazinga okugqoka afanayo futhi kuthuthukise impilo ende yoMshini Wokugaya Umhlathi.

Amasu Okugcina kanye Nokuqapha I-Wear

Amasu okugcina asebenzayo anciphisa ukuguga futhi avimbele ukwehluleka okungalindelekile. Abasebenzisi bancike ku:

- Ukunakekelwa okuvimbelayo, okubandakanya ukuhlolwa okuhleliwe kanye nokushintshwa kwengxenye ngaphambi kokuthi kwenzeke ukwehluleka.

- Ukugcinwa kokubikezela, ukusebenzisa izinzwa namathuluzi okuqapha ukuze kutholwe izimo ezingavamile kusenesikhathi futhi kuhlelwe ukulungisa ngesikhathi.

- Amasistimu okuqapha athuthukile, njengezinzwa ze-ultrasonic ne-telematics, ahlinzeka ngedatha yesikhathi sangempela ngamaleveli okuphakelayo nesimo semishini.

Ama-opharetha asebenzisa lawa masu ukuze alandelele ukuqhubeka kokugqoka futhi alungise imisebenzi njengoba kudingeka. Ukuqapha kwesikhathi sangempela kanye nokuzenzakalela kusiza ukugcina ukugeleza kwezinto ezinzile, ukunciphisa ukuguga, nokuthuthukisa ukusebenza kwe-crusher.

Ithiphu: Ukuhlanganisa ukunakekelwa okuvimbelayo nokubikezela ngobuchwepheshe besimanje bokuqapha kuholela empilweni ende kanye nokuvalwa okungahleliwe okumbalwa.

Izindlela Eziqagelayo Zengxenye Yempilo Enwetshiwe

Imisebenzi yesimanje yezimboni incike ekunakekeleni okubikezelwayo ukuze kugcinwe imishini yokugaya imihlathi isebenza kahle. Izindlela zokubikezela zisebenzisa ubuchwepheshe kanye nokuqapha okuvamile ukuze kubonwe izinkinga ngaphambi kokuba zidale umonakalo. Ama-opharetha anganweba impilo yezingxenye ze-jaw crusher ngokulandela lezi zindlela ezihlakaniphile:

- Faka izinzwa ukuze ugade izinga lokushisa likawoyela wokugcoba nesimo sokuhlunga. Ukutholwa kusenesikhathi kwezinguquko kukhombisa izinkinga ezingaba khona.

- Hlela ukuhlola kwansuku zonke, kweviki, kanye nokwenyanga usebenzisa izinhlu zokuhlola ezinemininingwane. Ukuhlola okuvamile kusiza ukubamba ukuguga ngaphambi kokuthi kube nzima.

- Khetha amapuleti emihlathi anokuqukethwe okuphezulu kwe-manganese, njenge-ZGMn13. Lezi zinto zihlala isikhathi eside ngaphansi kwezimo ezinzima.

- Qinisa amabhawodi namantongomane, bese uqondanisa iziqongo zamazinyo nezigodi. Ukuhlanganiswa okulungile kuvimbela ukuguga okungalingani kanye nokwehluleka kwengxenye yokuqala.

- Engeza amadivayisi okunciphisa ukudlidliza futhi ulawule izinga lokuphakelayo. Lezi zinyathelo zinciphisa ukucindezeleka ku-crusher futhi zinciphise ukuguga.

Ama-opharetha abasebenzisa ukulungiswa okubikezelwayo babona ukuphuka okungalindelekile okumbalwa kanye nempilo ende.

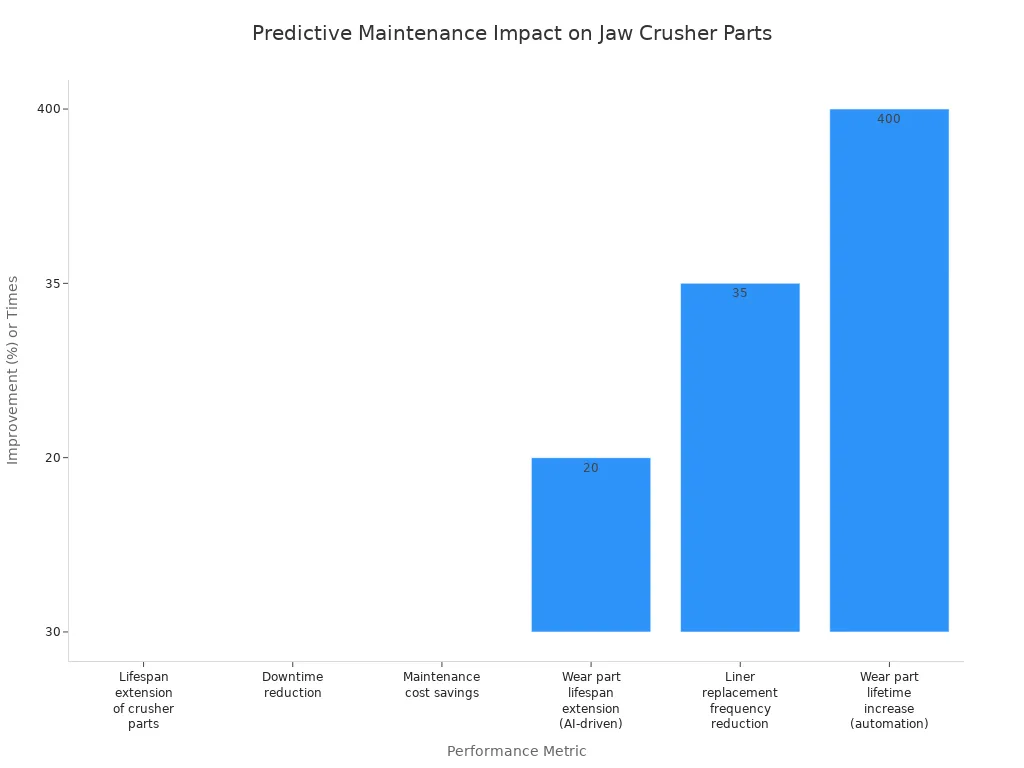

Idatha yomhlaba wangempela ibonisa umthelela walawa maqhinga. Ithebula elingezansi ligqamisa ukuthuthukiswa okubalulekile kusukela ekulungiseni okubikezelwayo:

| Imethrikhi yokusebenza | Izibalo Zokuthuthukisa | Incazelo Yomthelela |

|---|---|---|

| Ukwandiswa kwesikhathi sokuphila kwezingxenye ze-crusher | Kufika ku-30% | Izinto ezisezingeni eliphezulu nokunakekelwa okubikezelwayo kunciphisa ukushintshwa. |

| Ukuncishiswa kwesikhathi sokuphumula | Kufika ku-30% | Izinzwa ezihlakaniphile nokutholwa kusenesikhathi kusika izitobhi ezingahleliwe. |

| Ukonga izindleko zesondlo | Kufika ku-30% | Ukunakekela okusekelwe ezidingweni kwehlisa izindleko. |

| Isandiso sesikhathi sempilo ye-Wear part (okushayelwa yi-AI) | 15-20% | I-AI kanye ne-automation kukhulisa ukuqina. |

| Ukunciphisa imvamisa yokushintshwa kolayini | 35% | Amathuluzi okubikezela asho izinguquko ezimbalwa zolayini. |

| Ukwengeza okuyingxenye yokuphila konke (okuzenzakalelayo) | 2 kuya ku-4 izikhathi | Ukulungiselela okuzenzakalelayo kwandisa kakhulu ingxenye yempilo. |

Amasistimu okulawula ama-smart crusher, afana nalawo asetshenziswa emisebenzini ehamba phambili, andise ubude besikhathi sokuphila ngo-15-20%. Imicimbi yesikhathi sokuphumula yehle ngo-40%, futhi imvamisa yokushintshwa kwe-liner yehle ngo-35%. Izinzwa ezilandelela izinga lokushisa, ukudlidliza, nokugqoka zisiza opharetha ukuthi benze okuthile ngaphambi kokuthi kwenzeke ukwehluleka. Lolu shintsho lusuka ekusebenzeni ngendlela esebenzayo luye ekulungiseni okubikezelwayo lugcina imishini isebenza isikhathi eside futhi yonga imali. Izindlela zokubikezela zinikeza opharetha ukulawula okwengeziwe nokuzethemba ekusebenzeni kwabo kwe-gaw crusher.

Imikhuba Engcono Kakhulu Yokuthuthukisa Umshini Wokuhlikihla Emhlathini Ingxenye Yempilo

Ukufanisa I-Jaw Plate Material Nezici Zokufunza

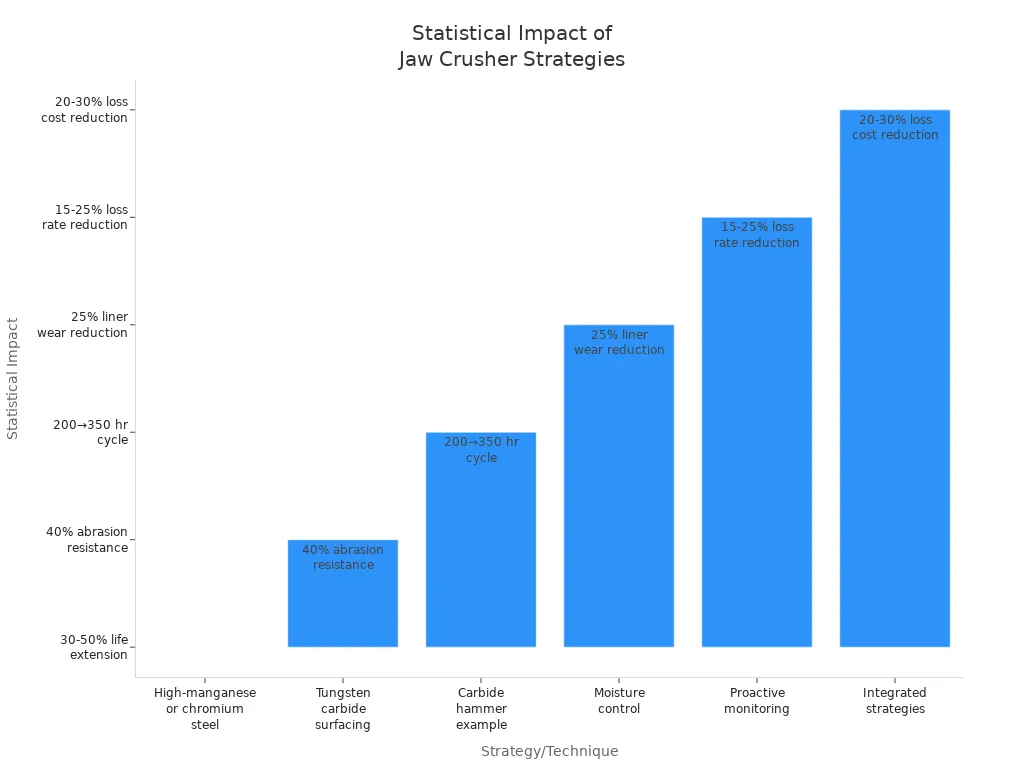

Ukukhetha okubalulekile kwepuleti lomhlathi kanye nomklamo kubalulekile ekwandiseni impilo yengxenye ye-crusher. Abasebenzisi kufanele:

- Khetha ama-alloys amapuleti emihlathi asuselwa ku-abrasiveness. Ingxubevange ye-M1 isebenza kahle ezintweni ezihunyushwa kancane njenge-limestone. Ama-alloys e-Premium njenge-M2, M7, M8, noma i-M9 angcono ezintweni eziqhuma kakhulu njenge-granite noma insimbi yensimbi.

- Qondanisa amaphethini amazinyo nesiphakeli. Amazinyo Abanzi (WT) asiza ngokudla okunenhlawulo ephezulu ngokuvimbela ukupakisha. Amazinyo Abukhali (ST) abamba okuphakelayo okuxegayo noma okungama-angular, okunciphisa ukushelela. Amapuleti Aqinile (CC), I-Heavy Duty (HD), noma I-Ultra Thick (UT) amelana nokuphakelayo.

- Landela izincomo zemodeli ye-crusher. Isibonelo, ama-crusher e-CJ615 avame ukusebenzisa amapuleti ama-Coarse Corrugated noma Heavy Duty ane-M8 alloy ukuze uthole okuphakelayo okulimazayo.

- Zungezisa amapuleti emihlathi phakathi nomjikelezo wokuphila kwawo ukuze uqinisekise ukuguga nokugcina i-nip angle ehamba phambili.

- Lungisa izilungiselelo ze-crusher, njengesilungiselelo eseceleni esivaliwe kanye ne-nip angle, ukuze ihambisane nezakhiwo zokuphakelayo.

Ukufanisa okokusebenza kwepuleti lomhlathi kanye nedizayini kuzici zokuphakelayo kusiza ukuthuthukisa ukusebenza nokwelula ingxenye yempilo.

Ukuhlolwa Okuvamile Nokushintshwa Kwangesikhathi

Ukuhlolwa okujwayelekile kanye nokushintshwa ngokushesha kwezingxenye ezigugile kugcina ama-crusher esebenza kahle. Abasebenzisi bayazuza kulokhu:

- Ukutholwa kusenesikhathi kokuguga nokulimala ngokuhlolwa okujwayelekile kwamapuleti emihlathi, ama-bearing, nezinye izakhi.

- Ukushintshwa okufika ngesikhathi kwezingxenye ezigugile, okuvimbela ukulimala okwengeziwe futhi kugcina ukusebenza kahle kokuchotshozwa.

- Ukugcotshwa okufanele kwezingxenye ezihambayo, kunciphisa ukungqubuzana nokwelula isikhathi sokuphila komshini.

- Amasistimu okuqapha axwayisa opharetha ngezinkinga, asekela ukulungiswa kusenesikhathi kanye nokwehlisa izindleko zokulungisa.

Isheduli yokulungisa engaguquki, ehlanganisa ukuhlolwa kanye nokushintshwa kwengxenye okufika ngesikhathi, yandisa isikhathi sokusebenza kwemishini futhi inciphisa izindleko zokusebenza.

Ukuqeqeshwa Koopharetha Nokuthuthukisa Inqubo

Ama-opharetha aqeqeshwe kahle nezinqubo ezithuthukisiwe zidlala indima ebalulekile ekwehliseni ukuguga. Abasebenzisi kufanele:

- Sebenzisa ukuhlukaniswa okuphakelayo okufanele nokulawula izinga lokuphakelayo ukuze uthuthukise umthamo futhi unciphise ukuguga.

- Lungisa izilungiselelo ze-crusher, ezifana nesilungiselelo eseceleni esivaliwe, usebenzisa ama-shim nobude bokuguqula ukuze unxephezele ukuguga.

- Kala igebe phakathi kwemihlathi ukuze uqinisekise izilungiselelo ezifanele.

- Yenza ukulungisa kuphela uma i-crusher ingenalutho futhi imisiwe ukuze ugweme ukuguga ngaphambi kwesikhathi.

- Thembela kumasistimu okugcoba okuzenzakalelayo ukuze uthole ukuthambisa okuhambisanayo.

- Qonda amasu okuphakela kanye nezinqubo zokulungisa ukuze unciphise ukuguga nokwelula impilo yomshini.

Ukuqeqeshwa komsebenzisi kanye nokwenza ngcono inqubo kuqinisekisa ukusebenza okuthembekile futhi kwandise isikhathi sokuphila sezingxenye ze-crusher.

Impahla yesiphakeli ishayela amanani okugqoka kanye nempilo yesevisiizingxenye ze-crusherkuzilungiselelo zezimboni. Ama-opharetha asebenzisa ukuqapha okuqinile, akhethe izinto ezingagugi, futhi alungise imisebenzi anganweba ingxenye yempilo ngokufika ku-50% futhi ehlise izindleko zokulungisa. Izilinganiso zemboni zibonisa ukuthi izinqubo ezingcono kakhulu zehlisa izindleko zokusebenza ngo-10%–20% futhi zenyusa ubude bemishini ngo-15%. Lokhu kuthuthukiswa kuholela ekukhiqizeni okuphezulu kanye nembuyiselo eqinile ekutshalweni kwezimali.

FAQ

Iyiphi impahla yesiphakeli edala ukuguga kwepuleti lomhlathi elisheshayo?

Ubulukhuni kanye nokuhubeka kubangela ukuguga okusheshayo. Amatshe aqinile njenge-granite noma amaminerali ane-quartz agaya ngokumelene namapuleti emihlathi. Ama-opharetha abona ukushintshwa okuvame kakhulu lapho ecubungula lezi zinto zokusebenza.

Ngabe umswakama osentweni yokuphakelayo uzithinta kanjani izingxenye ze-jaw crusher?

Umswakama ungaholela ekuvaleni nasekugqokeni okungalingani. Izinto ezinamathelayo, ikakhulukazi ezinobumba, zakha ngaphakathi kwe-crusher. Lokhu kwakha kwandisa ingcindezi ezingxenyeni futhi kungase kubangele ukuguga ngokushesha.

Ingabe opharetha banganciphisa ukuguga ngokulungisa usayizi wesiphakeli?

Yebo. Ama-opharetha alawula usayizi wokuphakelayo futhi asuse amatshe amakhulu noma izinhlawulo zisiza ukusabalalisa ukuguga ngokulinganayo. Lo mkhuba welula impilo yamapuleti emhlathi futhi uthuthukisa ukusebenza kahle kwe-crusher.

Yikuphi okubalulekile kwepuleti lemihlathi okusebenza kangcono kokuphakelayo okulimazayo?

Insimbi ye-Manganesenge-chromium ephezulu noma i-TIC efakwayo imelana nokugqokwa kwe-abrasive. Lezi zinto zibamba amatshe aqinile nahubhukayo, anikeza impilo ende yesevisi.

Ingabe opharetha kufanele bahlole kangaki izingxenye zokugqoka ze-gaw crusher?

Abasebenzi kufanelehlola izingxenye zokugqokamasonto onke. Ukuhlola okuvamile kusiza ukubona izimpawu zomonakalo ekuqaleni. Ukushintshwa okufika ngesikhathi kuvimbela ukuwohloka okungalindelekile futhi kugcina i-crusher isebenza kahle.

Isikhathi sokuthumela: Jul-17-2025