Ubuchwepheshe bezingxenye ze-crusher bulokhu bucindezela imingcele ngo-2025. Izinkampani manje zisebenzisa i-automation ehlakaniphile, izinto ezingagugi, kanye nemiklamo yokonga amandla ukuze zithuthukise ukusebenza kahle nokuhlala isikhathi eside. Isibonelo, ukuqapha kwesikhathi sangempela kanye nezinhlelo ezihlanganisiwe zisiza ukunciphisa isikhathi sokuphumula futhi zinciphise ukusetshenziswa kwamandla kufika ku-30%.

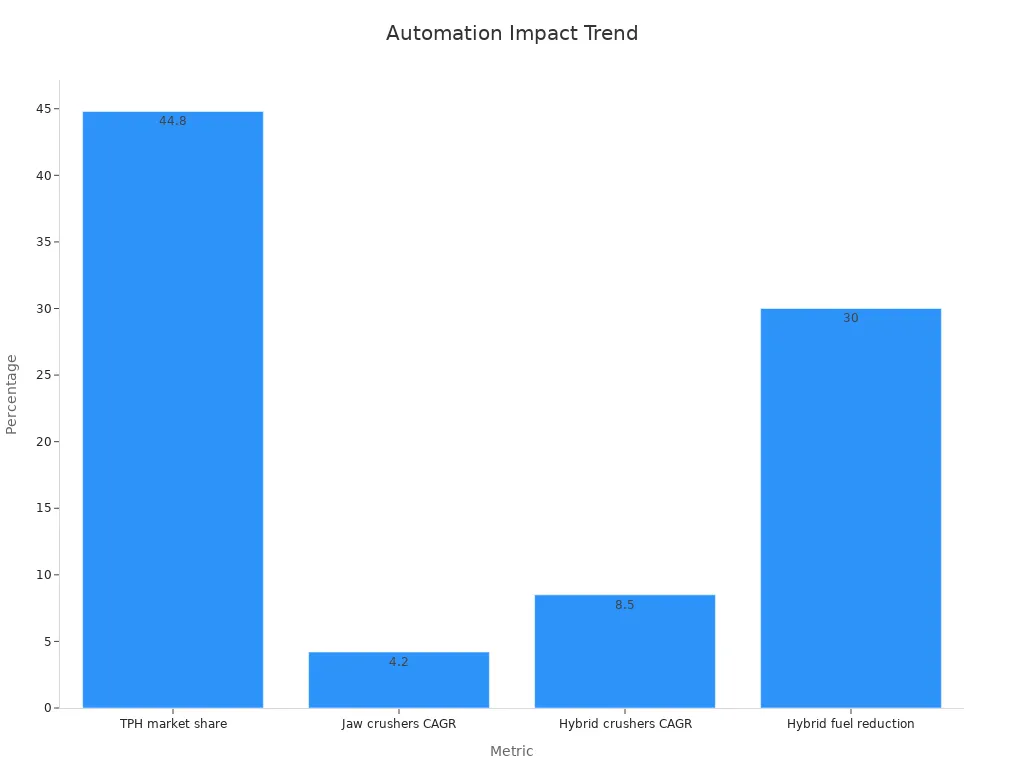

| Imethrikhi/Ithrendi | Inani/Izibalo | Umthelela Ekusebenzeni Kwe-Crusher ngo-2025 |

|---|---|---|

| Imali engenayo yokuguqula umhlathi owodwa (2024) | I-USD 1.8 billion | Ukubusa kwemakethe kwemiklamo ethuthukisiwe |

| 100–300 TPH ingxenye yesabelo somthamo (2024) | 44.8% | Kwenzelwe ukusebenza kahle kukaphethiloli kanye ne-automation |

| Ama-crusher amaHybrid abikezele i-CAGR | 8.5% | Ukuthuthukiswa kokusebenza kahle kwamandla |

Abasebenzisi babona izinzuzo zangempela nempilo ende yesevisi yeizingxenye zokugqoka ze-crusher, izindleko eziphansi zemishini yokugaya imihlathi, nezinketho eziguquguqukayo zeizingxenye ze-cone crusher, izingxenye ze-crusher, futhiIzingxenye ze-VSI crusher.

Okuthathwayo Okubalulekile

- Izinzwa ezihlakaniphile kanye ne-automation isiza ukuthola izinkinga kusenesikhathi,nciphisa isikhathi sokuphumula, futhi wonge imali yesondlo.

- Izinto ezithuthukisiwe nezingubo zokugqokayenza izingxenye ze-crusher zihlale isikhathi eside, zisebenze kangcono, futhi zinciphise izindleko zokushintshwa.

- Imiklamo eyonga amandla kanye nezilawuli zejubane eziguquguqukayo zinciphisa ukusetshenziswa kwamandla futhi zehlise nezindleko zokusebenza.

- Izingxenye ze-modular kanye ne-mobile crusher zivumela ukulungiswa okusheshayo, zithuthukise ukuphepha, futhi zinikeze izixazululo eziguquguqukayo zemisebenzi ehlukene.

- Amathuluzi e-AI nawedijithali abikezela ukwehluleka, athuthukise ukusebenza kahle, futhi andise impilo yemishini, akhulise ukukhiqiza kanye nezindleko zokusika.

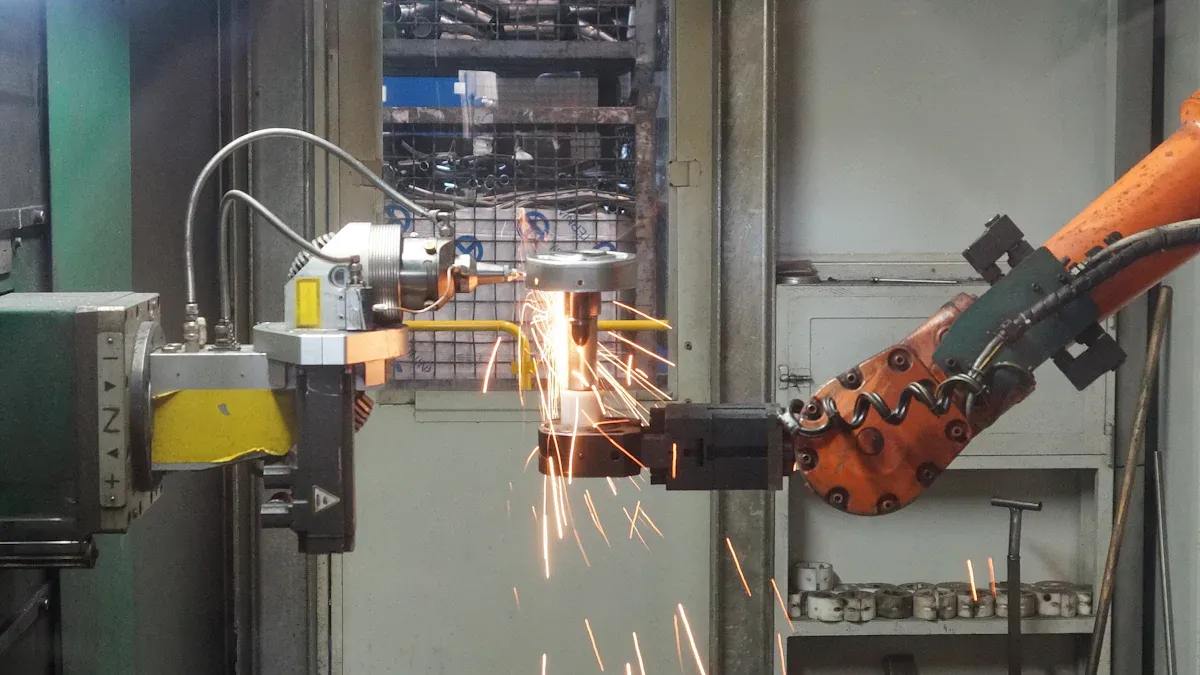

Izinzwa ezihlakaniphile kanye ne-Automation ezingxenyeni ze-Crusher

Ukuqapha Kwesikhathi Sangempela Nokugcinwa Kwezibikezelo

Izinzwa ezihlakaniphile manje zidlala indima enkulu ekugcineniizingxenye ze-crusheregijima kahle. Lezi zinzwa zilandelela impilo yemishini ngesikhathi sangempela. Ama-opharetha athola izibuyekezo ezibukhoma mayelana nezinga lokushisa, ukudlidliza, nokuguga. Lokhu kubasiza ukuthi babone izinkinga ngaphambi kokuba baphenduke izehluleki ezinkulu. Amasistimu okulungisa abikezelayo asebenzisa ukuhlaziya idatha ukuze athole amaphutha kusenesikhathi. Lokhu kusho ukuthi amaqembu angakwazi ukulungisa izinkinga ngaphambi kokuthi abangele ukungasebenzi.

- Amasistimu okugcoba azenzakalelayo ahlela imijikelezo yokugcoba ngokusekelwe kudatha yesikhathi sangempela, esiza ukuvimbela ukwehluleka ukuthwala.

- Izinzwa zokuqapha isimo zinikeza izibuyekezo ezibukhoma, ukuze opharetha bathathe isinyathelo ngokushesha.

- Ukulungiswa okubikezelwayo kushintsha ukulungiswa kusuka ohlelweni olumisiwe kuya endleleni esekelwe ezidingweni, ukonga isikhathi nemali.

- Ukuqapha ukugqokwa kwesikhathi sangempela kanye nezinhlaka zamawele edijithali zibikezela ukuguga kwamathuluzi, kunciphisa ukuphuka okungalindelekile.

- Amamodeli okufunda okujulile angabikezela ukuguga kwamathuluzi ngokunemba okuphezulu, okwenza ukulungiswa kuhlakaniphe.

Lawa mathuluzi ahlakaniphile asiza izinkampani zelule impilo yemishini futhi zinciphise izindleko zokuyilungisa.

Amasistimu Wokulungisa Azenzakalelayo Ezingxenye Ze-Crusher

Ukuzenzakalela akugcini ekuqapheni. Ama-crusher amaningi esimanje asebenzisa amasistimu okulungisa azenzakalelayo. Lawa masistimu ashintsha izilungiselelo njengobubanzi begebe noma izinga lokuphakelayo ngaphandle kokumisa umshini. Ama-opharetha angenza izinguquko ephanelini yokulawula noma ngisho bekude. Lokhu kugcina i-crusher isebenza kahle kakhulu futhi kunciphisa isidingo sokuhlola okwenziwa ngesandla.

- I-Powerscreen Pulse, isibonelo, inikeza imininingwane yesikhathi sangempela mayelana nesimo somshini, ukuguga, nezidingo zokunakekelwa.

- Izici ezifana ne-GPS ebukhoma, ukusebenza kahle kukaphethiloli, nemilayezo yamaphutha isiza opharetha ukuthi benze izinqumo ezisheshayo.

- Ukufinyelela kude kusho ukuthi amaqembu angaqapha futhi alungise izilungiselelo noma yikuphi.

I-Case Study: Ukunciphisa Isikhathi Sokuphumula Ngezingxenye Ze-Smart Crusher

Imiphumela yomhlaba wangempela ibonisa amandla e-smart automation. Izaziso zokuqagela zokulungisa emishinini yeCaterpillar zinciphisa isikhathi sokungasebenzi ngo-30%. Izinkampani zibona ukuthuthuka okungama-20% ekusebenzeni kahle futhi zonga kufika ku-$500,000 unyaka ngamunye. Amadeshibhodi esikhathi sangempela asize ukuhlela ukulungisa nokugcina imishini isebenza isikhathi eside.

Izinzwa ezihlakaniphile kanye ne-automationukusiza opharetha bagweme ukuphahlazeka okumba eqolo futhi bagcine izingxenye ze-crusher zisebenza kanzima isikhathi eside.

Izinto Ezithuthukisiwe Ezimelana Nezinsimbi Zezingxenye Zokugawula

Ama-alloys esizukulwane esilandelayo kanye nama-Composites

Ama-alloys amasha nezinhlanganisela ziyashintsha ukuthi izingxenye ze-crusher zihlala isikhathi eside kangakanani. I-Metal Matrix Composites (MMC) iyagqama ngoba ingahlala isikhathi esiphindwe kathathu kunezinto ezindala. Ezinye izingxenye, njenge-Rock Box spider arm liner, manje zinikeza impilo yokugqoka engu-300%. Lokhu kusho ukuthi isikhathi sokuphumula sincane kanye nokushintshwa okumbalwa.Ama-racks okufakwa kwe-concave athuthukilefuthi ukusiza ngokusika isikhathi sokufaka phakathi, okwenza ukugcinwa kuphephe futhi kusheshe. Onjiniyela basebenzisa ukuskena kwe-laser ye-3D ukuze balandelele ukuguga nokuthuthukisa ukwakheka kwamagumbi e-crusher. Lokhu kungaphinda kabili impilo yokuguga kwezinye izingxenye. Lokhu kuthuthukiswa kwenza izingxenye ze-crusher zibe namandla, ziphephe, futhi zithembeke nakakhulu.

- Ukuhlolwa kokugqoka kwenkundla kubeka izinto ezisetshenziswayo ezimweni zangempela zezimayini, okunikeza imiphumela yomhlaba wangempela.

- Ama-alloy ahlukene, njengama-carbon steels ne-white cast iron, abonisa umehluko omkhulu endleleni amelana ngayo nokugqokwa.

- Izimpahla ezingcono zisho izindleko eziphansi zokushintshwa, abasebenzi, kanye nokulahleka kokukhiqiza.

- Ukumodela kwekhompiyutha kusiza ososayensi baklame izinto eziqinile ngokufunda amandla abo nokuthi ziphuka kanjani.

I-Ceramic kanye ne-Polymer Coatings yezingxenye ze-Crusher

Izembatho ze-Ceramic ne-polymer zengeza olunye ungqimba lokuvikela. Lezi zimbotshana zisiza izingxenye ze-crusher ukuthi zimelane nokuklwebheka, ukushisa nokugqwala. Izembatho ze-Ceramic zinzima kakhulu futhi zingakwazi ukusingatha imisebenzi enzima, kuyilapho izimbobo ze-polymer zilula futhi zinciphisa ukungqubuzana. Ndawonye, asiza izingxenye ze-crusher zihlale isikhathi eside futhi zisebenze kangcono. Okunye ukumboza okusha kuze kusize ukonga amandla ngokunciphisa amandla adingekayo ukuze kuchotshozwe amadwala. Lokhu kusho ukuthi imishini isebenzisa amandla amancane futhi ihlala kusevisi isikhathi eside.

- Isihloli esikhethekile sohlobo lwe-jaw crusher sibonisa ukuthi ukuguga namandla kuxhumene eduze.

- Ukuguga okuncane kusho amandla amoshekayo amancane, ngakho ama-crusher asebenza kahle kakhulu.

Traditional vs. Advanced Crusher Parts Materials

| Imethrikhi | I-Advanced Crusher Liners (isb, iBanga 846 lensimbi yemanganese) | Imigqa Yendabuko/Yekhwalithi Ephansi |

|---|---|---|

| Gqoka Ukuphila | Cishe ngo-2x ubude | Isisekelo |

| Ukuchoboza Ukusebenza kahle | 35% kangcono | Isisekelo |

| Ukuthuthukiswa Kokusebenza | Yebo | No |

| Ukuncishiswa Kokudonsa Amandla | Yebo | No |

| Ukusebenza Kwezisetshenziswa | Yebo | No |

Izinto ezithuthukisiwe ezifana nensimbi ye-manganese yeBanga 846 zine-manganese ne-carbon eyengeziwe. Lokhu kubhalansi kubanika ubulukhuni obungcono nokuqina. Izinto zendabuko azihlali isikhathi eside futhi zidinga ukushintshwa kaningi. Ezinye izinhlanganisela ezithuthukisiwe, njenge-carbon fibre-reinforced polymer, zinamandla kakhulu kodwa zingaba brittle futhi zibiza ngaphezulu. Okwamanje, ukuxuba izinsimbi nezinhlanganisela kunikeza imiphumela engcono kakhulu yezingxenye ze-crusher.

Ukukhetha izinto ezisezingeni eliphezulu ezingagugi kusiza izinkampani zonge imali, zinciphise isikhathi sokuphumula, futhi zithole okwengeziwe ezingxenyeni zazo ze-crusher.

Amasu Okusebenzisa Amandla Ezingxenyeni Ze-Crusher

Imiklamo Yezingxenye Ze-Crusher Ezonga Amandla

Abakhiqizi manje bayaklamaizingxenye ze-crusherukusindisa amandla amaningi kunangaphambili. Ama-cone crushers anamuhla asebenzisa izici ezifana namadrayivu aguquguqukayo. Lawa madrayivu alungisa isivinini ngokuya ngokuthi kungakanani okudinga ukuchotshozwa. Lokhu kulungiswa okuhlakaniphile kungonga cishe u-20% ekusebenziseni amandla. Eminye imiklamo emisha ize isebenzise ama-levitation bearings kazibuthe. Lawa ma-bearings anciphisa ukusetshenziswa kwamandla kufika ku-30% futhi asiza izingxenye ukuthi zihlale isikhathi eside. Lapho izinkampani zikhetha i-crusher efanele yomsebenzi, zigwema ukuchitha amandla. Ukugcina usayizi wesiphakeli uzinzile nokusebenzisa izingxenye zekhwalithi ephezulu nakho kuyasiza. Ukuhlola okuvamile kumabha womthelela, amalayini, namabhande kugcina yonke into isebenza kahle nangempumelelo.

Ithiphu: Ukusebenzisa ama-hybridi noma ama-crusher kagesi ane-smart automation kungehlisa izikweletu zikaphethiloli nogesi nakakhulu.

Ama-Speed Drives nezilawuli Eziguquguqukayo Ezingxenyeni Ze-Crusher

Amadrayivu esivinini aguquguqukayo (ama-VSD) nezinhlelo zokulawula enza umehluko omkhulu endleleni ama-crusher asebenza ngayo. Ama-VSD avumela opharetha balawule isivinini samamotho ngokunemba okukhulu. Lokhu kusho ukuthi i-crusher isebenzisa kuphela amandla amaningi njengoba idinga. Lapho umshini uqala, ama-VSD ehlisa ukugijima kukagesi, okuvikela injini futhi onge amandla. Lawa madrayivu asiza futhi ekwehliseni ukuguga ezingxenyeni ezithile futhi ehlise imfucuza. Ngokuxhuma ama-VSD ezinhlelweni zokulawula ezihlakaniphile, amaqembu angabuka ukusetshenziswa kwamandla ngesikhathi sangempela futhi abone noma yiziphi izinkinga ngokushesha. Lokhu kugcina i-crusher isebenza kahle kakhulu futhi kusiza ukugwema ukulungiswa okumba eqolo.

Umthelela Wezindleko Zokusebenza Zezingxenye Zokuhlikihla Ezonga Amandla

Izingxenye ze-crusher ezonga amandla zisiza izinkampani ukuthi zonge imali nsuku zonke. E-Clarabelle Mill, ukusebenzisa ama-crushers ngomthamo ophelele wedizayini kwehlisa ukusetshenziswa kwamandla futhi kwehlise nezindleko zikagesi. Uma okokusebenza kusebenza kahle kakhulu, kunezinhlawulo ezimbalwa zamandla. Izinkampani ezisebenzisa ukunakekelwa okubikezelwayo zisebenzisa u-20-30% ngaphansi ekulungiseni. Baphinde babone ukukhuphuka okungu-10-20% kokuthi imishini yabo itholakala kaningi kangakanani. Ithebula elingezansi libonisa ukuthi izindlela ezihlukene zokonga zisebenza kanjani:

| Indlela Yokuhlaziya Izindleko | Incazelo |

|---|---|

| Ukuhlaziywa Kwezindleko Zokuphila | Ibheka zonke izindleko empilweni yonke yezinto zokusebenza, okuhlanganisa amandla nokulungiswa. |

| Isamba Sezindleko Zobunikazi | Ingeza izindleko ezigxilile neziguquguqukayo ukuze ubone ukonga kwesikhathi eside. |

| Ukugcinwa Okubikezelwayo | Yehlisa izindleko zokulungisa kufika ku-30%. |

| Ukunakekela Okuthuthukisiwe | Yandisa ukusetshenziswa kwemishini futhi yonge imali eyengeziwe. |

Ukukhetha izingxenye ze-crusher ezonga amandla kuholela ezindlekweni eziphansi, isikhathi esincane sokuphumula, nokusebenza okungcono.

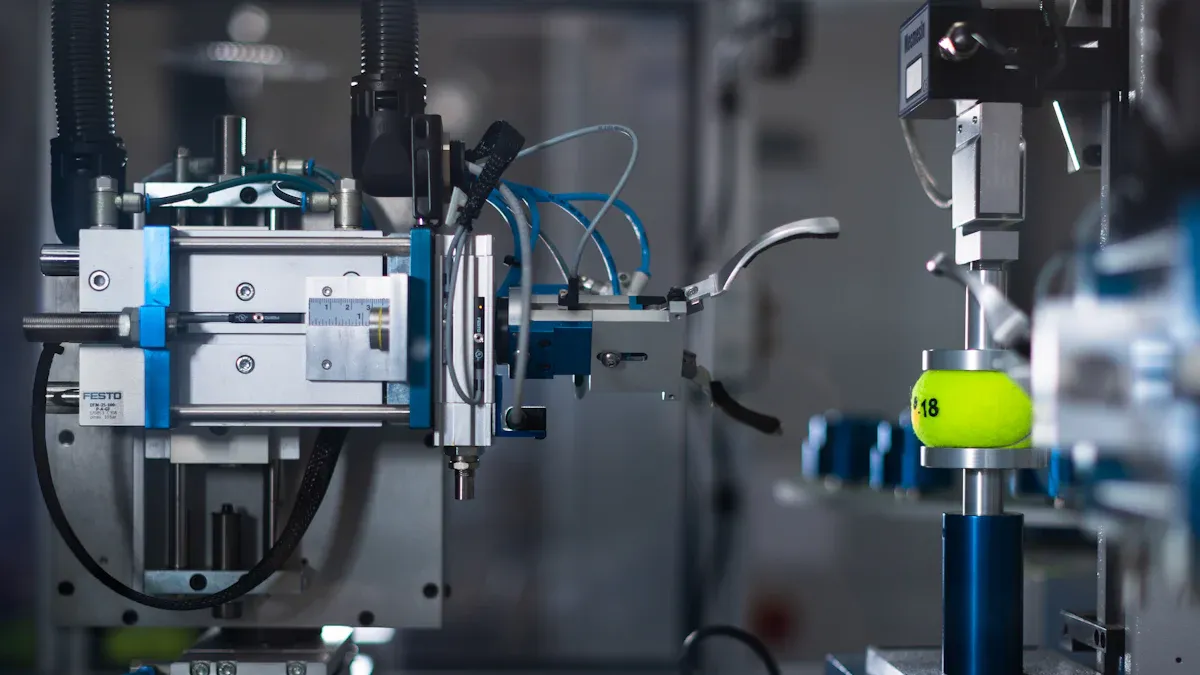

Izixazululo zezingxenye ze-Modular kanye ne-Mobile Crusher

Shintsha Izingxenye Ze-Modular Crusher Ezisheshayo

Amasistimu emojuli ashintsha ngokushesha ashintshe indlela amaqembu aphatha ngayoukugcinwa kwe-crusher. Lezi zinhlelo zivumela abasebenzi ukuthi bashintshe izingxenye ezigugile ngokushesha, ngokuvamile ngaphandle kwamathuluzi akhethekile. Idizayini ye-modular isho ukuthi amaqembu angaxuba futhi afanise ama-crusher, izikrini, nama-conveyors ukuze alingane nomsebenzi ngamunye. Lokhu kuvumelana nezimo kusiza izinkampani ukuthi zibhekane nezinto ezahlukahlukene nezidingo zesayithi kalula. Amakamelo okuchotshozwa anamandla aphezulu athuthukisa ukukhiqiza futhi asike amabhodlela. Ukuzenzakalela nokuqapha okukude, njenge-Pulse telematics, kugcina imishini isebenza isikhathi eside ngokuxwayisa amaqembu ngezinkinga ngaphambi kokuthi zibe izinkinga.

- Izingxenye ze-Modular zinciphisa isikhathi sokuphumula ngesikhathi sokulungiswa.

- Amaqembu angakwazi ukwenza ngendlela oyifisayo ukusetha kwephrojekthi ngayinye.

- Ukuphepha kuba ngcono ngoba abasebenzi bachitha isikhathi esincane bephethe izingxenye ezinzima.

Ithiphu: Amasistimu e-modular aphinde asekele amayunithi amandla akonga amandla, asize izinkampani zihlangabezane namazinga okukhishwa kwekhabhoni kanye nemigomo yokusimama.

Izingxenye ze-Mobile Crusher Zokusebenza Okuguquguqukayo

Izingxenye ze-crusher zamaselula ziletha izinga elisha lokuguquguquka kumasayithi omsebenzi. Lezi zingxenye zifika zifakwe ku-chassis enamasondo noma elandelwayo, ukuze amaqembu akwazi ukuzisusa ngokushesha ukusuka kwesinye isayithi ukuya kwenye. Ama-crushers eselula ngokuvamile aqala ukusebenza phakathi nemizuzu engama-30 kuya emahoreni ambalwa ngemva kokufika. Lokhu kuthunyelwa okusheshayo konga isikhathi nemali. Ukuchotshozwa endaweni kusho ukuthuthwa okuncane kwezinto ezingavuthiwe, okwehlisa izindleko zokuthutha kanye nokungcola. Ama-crushers amaselula aphatha inhlobonhlobo yezinto zokwakha, kusukela ezimayini kuye ekugayweni kabusha, futhi azivumelanisa nezimo ezishintshayo zesayithi.

| Isici | I-Mobile Crusher | I-Stationary Crusher |

|---|---|---|

| Ukuhamba | Ihamba kalula phakathi kwamasayithi | Kulungiswe endaweni eyodwa |

| Isikhathi Sokuthunyelwa | Imizuzu engama-30 ukuya emahoreni | Kudingeka ukusetha isikhathi eside |

| Amandla | 225-1000 amathani/ihora | Kufika ku-2000+ amathani/ihora |

| Ukuvumelana nezimo | Phezulu | Phansi |

| Izindleko Zokulungisa | Phezulu | Phansi |

| Umthelela Wezemvelo | Ukuthutha okuncane okudingekayo | Idinga ukulawula uthuli |

| Ubude bempilo | Kafushane | Mude |

Ama-crushers eselula asetshenziswai-rotor modular kanye nezinhlelo zamathuluzi. Amaqembu angakwazi ukulungisa lokhu ukuze enze izinto ezihlukahlukene, okuthuthukisa ukusebenza kahle futhi andise impilo yengxenye yokugqoka.

Ukwehliswa Kwesikhathi Sokulungisa Ngezingxenye Ze-Modular Crusher

Izingxenye ze-crusher Modular zenza ukunakekelwa kusheshe kakhulu. Amaqembu awasadingi ukuchitha amahora noma izinsuku ekulungiseni. Amasistimu okushintsha ngokushesha avumela abasebenzi ukuthi bashintshe izingxenye ezigugile ngesikhathi esincane, okugcina imishini isebenza. Le ndlela iphinde yehlise ukuphatha ngesandla, okwenza inqubo iphephe futhi ibe lula. Izinkampani zibona isikhathi esincane sokungasebenzi kanye nezindleko eziphansi zabasebenzi. Amathimba asiza ngokuzenzakalelayo nokuqapha okukude ukuhlela ukunakekelwa ngaphambi kokwehlukana.

- Ukushintshaniswa kwezingxenye ngokushesha kusho isikhathi esengeziwe.

- Umsebenzi omncane wezandla uthuthukisa ukuphepha kanye ne-ergonomics.

- Ukucubungula endaweni kunciphisa ukubambezeleka kwezokuthutha nokulungisa.

Izinkampani ezisebenzisa izixazululo ze-modular neselula zibona izinzuzo zangempela ekukhiqizeni, ukuphepha, nokonga izindleko.

Ukwenza Idijithali kanye Nokugcinwa Okuqagelayo Kwezingxenye Zokugawula

Izibalo Zedatha Zokusebenza Kwezingxenye Ze-Crusher

Ukuhlaziya idatha manje kusiza izinkampani ukuthi zithole okuningi kumishini yazo. Ngokusebenzisa amathuluzi edijithali, amaqembu angakwazi ukulandelela ukuthi ama-crusher asebenza kanjani ngesikhathi sangempela. I-Design of Experiments (DoE) ivumela onjiniyela bahlole izilungiselelo ezihlukene futhi babone ukuthi izinguquko ziwuthinta kanjani umphumela. Bangabona amaphethini izindlela zakudala ezingagejiwe. Isibonelo, bangabona ukuthi isivinini kanye nosayizi wegebe kusebenza kanjani ndawonye ukushintsha ukusebenza. Amaqembu asebenzisa amasampula okusika ibhande kanye nokuqapha kokucubungula ukuze aqoqe idatha. Lokhu kubasiza ukuthi balungise imishini ukuze bathole imiphumela engcono. Ukuhlolwa kwedijithali kwenza kube lula ukuhlela nokuthuthukisa ukukhiqiza.

- Onjiniyela basebenzisa izibalo ze-oda lokuqala nelesibili ukuze benze imodeli yokusebenza kwe-crusher.

- Ukuqapha okuqhubekayo kusiza amaqembu ukuthi ahlangabezane namazinga omkhiqizo nezidingo zemakethe.

Ama-Predictive Maintenance Platform for Crusher Parts

Izinkundla zokulungisa ezibikezelayo zisebenzisa idatha yesikhathi sangempela ukugcina imishini isebenza isikhathi eside. I-Nukon yakhe ideshibhodi ye-Newcrest Mining ebikezela ukuthi izoshintshwa niniamalayini. Leli thuluzi lisebenzisa idatha ebukhoma namamodeli wokuhlehla ukuhlela ukulungiswa. Amaqembu awasaqageli ukuthi azilungisa nini izingxenye. Bathola izexwayiso ngaphambi kwezinkinga. Le ndlela ithatha indawo yezindlela ezindala, ezenziwe ngezandla futhi yenza ukuhlela kube lula. Umphumela uwukuhlela okungcono kanye nama-crusher anokwethenjelwa.

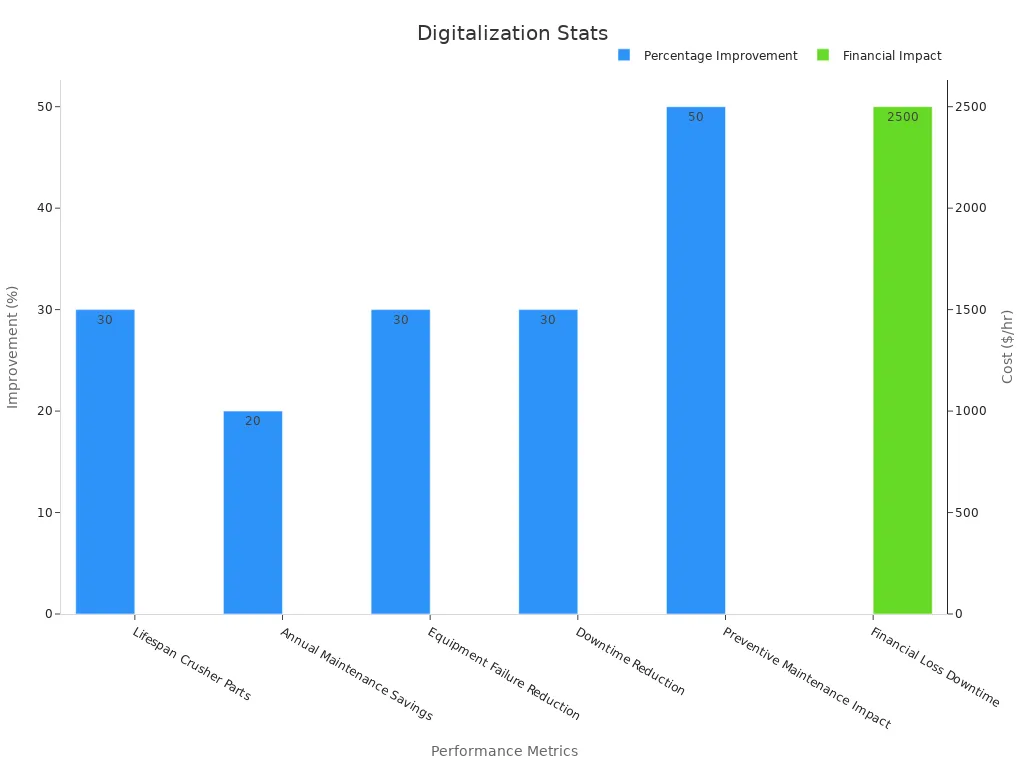

| Imethrikhi yokusebenza | Izibalo Zokuthuthukisa | Incazelo Yomthelela |

|---|---|---|

| Ukwandiswa kwesikhathi sokuphila kwezingxenye ze-crusher | Kufika ku-30% | Ukusebenzisa izinto zekhwalithi ephezulu kwandisa ingxenye yokuphila, kunciphisa imvamisa yokushintshanisa. |

| Ukonga izindleko zonyaka | Kufika ku-20% | Izingxenye ze-Premium nokulungiswa okuthuthukisiwe kunciphisa izindleko zonyaka zokulungisa. |

| Ukunciphisa amathuba okuhluleka kwemishini | Kufika ku-30% | Ukunakekelwa okuvimbelayo kwehlisa ingozi yokwehluleka, kuthuthukisa ukusebenza kahle. |

| Ukuncishiswa kwesikhathi sokuphumula | Kufika ku-30% | Ukutshala imali ezingxenyeni ze-premium kunciphisa kakhulu isikhathi sokuphumula esingahleliwe. |

| Ukulahlekelwa yimali ngenxa yesikhathi sokuphumula esingahleliwe | Cishe. $2,500 ngehora | Igqamisa umthelela wezindleko zesikhathi sokuphumula, igcizelela inani lesikhathi esithuthukisiwe. |

| Umthelela wokuvikela wokulungisa ekuhlulekeni | Kufikela ku-50% ukuncishiswa | Ukulungiswa okuhleliwe kunciphisa ukuhluleka komshini, ukuthuthukisa ukwethembeka kanye nesikhathi. |

Ukulungiswa kokuqagela kusiza amaqembu agweme ukuphahlazeka okumba eqolo futhi kugcine ama-crusher esebenza ngokusemandleni awo.

Ukunweba Ubude Besikhathi Sezingxenye Ze-Crusher Ngamathuluzi Edijithali

Amathuluzi edijithali asiza ukunweba impilo yezingxenye ze-crusher. Isofthiwe yesondlo ithumela izikhumbuzi namarekhodi ezitolo. Lokhu kugcina ukuhlolwa kusesikhathini futhi kusiza amaqembu alungise izinkinga kusenesikhathi. Izinzwa zokudlidliza nezinga lokushisa zibona amabhawodi axegayo noma ukushisa ngokweqile ngaphambi kokuba kwenzeke ukwehluleka. Amasistimu okugcoba azenzakalelayo aletha inani elifanele lamafutha, amisa kufika ku-75% wokwehluleka ukuthwala. Lawa mathuluzi anciphisa isikhathi sokungasebenzi ngokufika ku-30% futhi ehlise izindleko zokulungisa ngo-30%. Ukusebenza kahle kokuchotshozwa kungakhuphuka ngo-15% uma amaqembu esebenzisa amathuluzi edijithali ukuhlola okuvamile. Izinkampani zibona impilo yemishini ende kanye nezimanga ezimbalwa.

Ukwenza idijithali kunikeza opharetha ukulawula okwengeziwe, konga imali, futhi kugcina ama-crusher esebenza isikhathi eside.

I-Eco-Friendly and Sustainable Crusher Parts Practices

Izinto Ezisetshenziswa Kabusha Nezinomthelela Ophansi

Izinkampani eziningi manje ziyakhethaizinto ezisekela imigomo ye-3R: Nciphisa, Sebenzisa Kabusha, futhi Kabusha. Baklama izingxenye ze-crusher ukuze zihlale isikhathi eside futhi zigaywe kabusha ekupheleni kwempilo yazo. Embonini yensimbi, ubuchwepheshe obusha be-slag crusher busiza ukuguqula imfucuza ibe yizinsiza ezibalulekile. Le ndlela inciphisa udoti wokulahla imfucumfucu futhi isekela umnotho oyindilinga. Ukuhlaziywa kwe-Lifecycle kukhombisa ukuthi ukusebenzisa izinto ezigaywe kabusha, njengokhonkolo ophuma kudoti yokwakha, kwehlisa i-carbon footprint. Le mikhuba iphinde inciphise isidingo sezinto ezintsha zokusetshenziswa, ezisiza ukuvikela imithombo yemvelo. Amathimba agxile ekusetshenzisweni kabusha nempilo ende yomkhiqizo abona ukumosha okuncane kanye nezindleko eziphansi.

Ukwenziwa Konga Amandla Kwezingxenye Ze-Crusher

Ukukhiqiza okuwonga ugesi kuyashintsha indlela izingxenye ze-crusher zenziwa ngayo. Izinkampani zisebenzisa izilawuli ezizenzakalelayo nezihlakaniphile ukuze zinciphise ukusetshenziswa kwamandla ngesikhathi sokukhiqiza. Nawa amaqiniso abalulekile:

- Ukusetshenziswa kwamandla okuqondile kokuchoboza kuyahlukahluka kusuka ku-0.48 kuya ku-1.32 kWh ngethani ngalinye.

- Ukwenza kahle kokuphakelayo kanye nokuzenzela kunganciphisa ukusetshenziswa kwamandla ngo-10-30%.

- Imiklamo emisha nama-coatings asiza ukunciphisa ukungqubuzana, konga amandla engeziwe.

- Ukungqubuzana nokuguga kubangela ukulahlekelwa kwamandla amakhulu, kodwa ubuchwepheshe obusha bungase bunciphise lokhu ngo-30% eminyakeni engu-20 ezayo.

- Lezi zinguquko zingonga amandla afinyelela ku-550 TWh futhi zehlise amathani ayizigidi ezingama-290 we-CO2 unyaka ngamunye.

Ngokwenza izingxenye ze-crusher ngamandla amancane, izinkampani zisiza iplanethi futhi zonge imali.

Ukuthobela Imvelo KuCrusher Parts Technology

Ubuchwepheshe besimanje bezingxenye ze-crusher busiza izinkampani ukuthi zihlangabezane nemithetho eqinile yezemvelo. Nansi indlela:

- Ama-crusher manje anciphisa umthamo we-scrap, okwenza ukugaywa kabusha kube lula futhi kubaluleke kakhulu.

- Imishini ikhipha uketshezi lwamahhala olungafika ku-98% emfucumfucwini, ukusika imfucumfucu eyingozi.

- Amasistimu e-Briquetter afuna kabusha uketshezi olulahlwayo, ukuze izinkampani zikwazi ukuphinda zisebenzise.

- Amasistimu okuhlanza amanzi aphinde asebenzise amanzi, ehlise izindleko zokulahla kanye nokusiza ukuhlangabezana nemithethonqubo.

- Ama-crusher asebenza ngogesi kanye namasistimu okucindezela uthuli anciphisa ukungcola futhi agcine umoya uhlanzekile.

Lokhu kuthuthukiswa kusiza izinkampani ukuthi zilandele imithetho yezemvelo, zinciphise imfucuza, futhi zisekele ikusasa elihlanzekile.

Ukuhlanganiswa kwe-AI kanye Nokufunda Komshini Ezingxenyeni Ze-Crusher

I-AI-Driven Driven Failure Prediction for Crusher Parts

I-AI manje isiza amaqembu ukubikezela ukuthi niniizingxenye ze-crusheringase yehluleke. Amasistimu ahlakaniphile abuka izimpawu ezifana nokudlidliza, izinga lokushisa, noshintsho lokucindezela. Basebenzisa le datha ukuze babone izinkinga ngaphambi kokuthi zidale ukuphuka. Isibonelo, iSmart Crusher Control System ye-SBM embonini yensimbi yaseCanada yenza umehluko omkhulu. Isistimu ilungise izilungiselelo ngesikhathi sangempela nokulungiswa okuhleliwe ngaphambi kokuthi kwenzeke ukwehluleka. Lokhu kuholele ekwenyukeni ngo-22% kokuphumayo, ngo-40% ezenzakalweni ezimbalwa zesikhathi sokuphumula, kanye no-15% wokonga amandla. Abasebenzisi bathemba lawa mathuluzi e-AI ukugcina imishini isebenza isikhathi eside futhi igweme izimanga ezibizayo.

| Imethrikhi yokusebenza | Ukuthuthukiswa Okubangelwa Ukuhlanganiswa kwe-AI |

|---|---|

| Ukwenyuka Kokusebenza | Ukunyuka okungu-22% (kusuka ku-550 TPH kuya ku-670 TPH) |

| Ukunciphisa Isikhathi Sokuphumula | 40% izenzakalo ezimbalwa zesikhathi sokuphumula |

| Ukonga Amandla | Ukunciphisa ngo-15% ukusetshenziswa kwamandla |

| Isandiso Sokuphila Kwengxenye | I-15-20% yesikhathi eside sempilo yezingxenye ezigqokile |

| I-Liner Replacement Frequency | Ukwehliswa ngo-35% emayini ye-chromite yaseTurkey |

Ukuqagela ukwehluleka okushayelwa yi-AI kusho ukuqagela okuncane kanye nesikhathi esengeziwe somsebenzi ngamunye.

Ukuthuthukiswa Kwenqubo Okuzenzakalelayo Ezingxenyeni Ze-Crusher

Ukufunda ngomshini manje kusiza ama-crusher ukuthi asebenze ngobuhlakani, hhayi kanzima. Izilawuli ezizenzakalelayo zilungisa amanani okuphakelayo nezilungiselelo ukuze kugcinwe inqubo izinzile. Lokhu kusho usayizi womkhiqizo ongaguquki kanye nekhwalithi engcono. Amaqembu awasadingi ukubuka yonke imininingwane. Isistimu ithola indlela engcono kakhulu yokusebenzisa i-crusher futhi ibone izinkinga kusenesikhathi. Idatha yesikhathi sangempela isiza opharetha ukuthi benze izinqumo ezisheshayo. Isondlo siyashintsha sisuka ekulungiseni izinkinga ngemuva kokuthi kwenzekile kuzimise ngaphambi kokuthi ziqale.

| Ukusebenza kahle kwe-Metric | Incazelo Yokuthuthukisa |

|---|---|

| Ukusetshenziswa kwamandla | Kufika ku-30% ukuncishiswa kuye ngohlelo lokusebenza |

| Gqoka Ingxenye Ukuphila Konke | Ukwenyuka okuphindwe kabili kuya kokuphindwe kane kokuguga ingxenye yokuphila konke |

| Isikhathi esiphezulu | Ukwenyuka kwesikhathi ngenxa yoshintsho nokuma okumbalwa |

| Ukungaguquguquki Komkhiqizo | Usayizi womkhiqizo ongaguquki ngenxa yokushintshashintsha okuzenzakalelayo |

Ukuthuthukisa okuzenzakalelayo kuvumela amaqembu ukuthi athuthukise ukusebenza ngaphandle kokuchitha okwengeziwe kumishini emisha.

Amandla Esikhathi esizayo we-AI kuCrusher Parts Technology

Ikusasa libukeka liqhakazile ku-AI ezingxenyeni ze-crusher. Ochwepheshe balindele ukuthi imakethe ye-crusher yamatshe ikhule isuka ku-$5.2 billion ngo-2024 iye ku-$8.3 billion ngo-2033. I-automation eqhutshwa yi-AI, ukugcinwa kokubikezela, nokuqapha kwesikhathi sangempela kuzoqhuba lokhu kukhula. Amathuluzi amasha afana nombono wekhompyutha namarobhothi azosiza amaqembu asebenze ngokushesha nangokuphepha. Ukufunda ngomshini kuzoqhubeka nokwenza ngcono ukuthi ama-crusher asebenza kanjani, awenze asebenze kahle futhi athembeke.

- Imakethe kulindeleke ukuthi ikhule ku-CAGR engu-6.2% ukusuka ngo-2026 kuya ku-2033.

- Ukuhlanganiswa kwe-AI kuzogcina kwehlisa izindleko kanye nesikhathi sokuphumula.

- Izinkampani zizosebenzisa idatha eyengeziwe ukuze zenze ukukhetha okuhlakaniphile nokuhlala phambili.

Njengoba i-AI iqhubeka nokuvela, izingxenye ze-crusher zizohlala isikhathi eside, zisebenze kahle, futhi kube lula ukuziphatha.

Ubuchwepheshe bezingxenye ze-crusher bulokhu buqhubekela phambili. Izinkampani manje zisebenzisa amathuluzi ahlakaniphile, izinto ezingcono, nemiklamo yokonga amandla. Lezi zinguquko zisiza amaqembu ukuthi asebenze ngokushesha futhi onge imali. Benza futhi izingxenye ze-crusher zihlale isikhathi eside futhi zisize iplanethi. Noma ubani ofuna ukuqhubeka phambili kulo mkhakha udinga ukubuka lawa mathrendi. Imibono emisha ezingxenyeni ze-crusher izogcina ibumba imboni iminyaka ezayo.

FAQ

Yiziphi izinzuzo eziyinhloko zokusebenzisa izingxenye ze-smart crusher?

Ihlakaniphileizingxenye ze-crushersiza amaqembu abone izinkinga kusenesikhathi. Banciphisa isikhathi sokuphumula futhi balondoloze imali ekulungiseni. Abasebenzisi bathola izibuyekezo zesikhathi sangempela, ukuze bakwazi ukulungisa izinkinga ngaphambi kokuthi zibe izinkinga ezinkulu. Lezi zingxenye zisiza nemishini ukuthi ihlale isikhathi eside.

Izinto ezithuthukisiwe zikuthuthukisa kanjani ukusebenza kwengxenye ye-crusher?

Izinto ezithuthukilenjengama-alloys akhethekile nama-coatings enza izingxenye ze-crusher zibe nzima. Bamelana nokugqoka nokushisa kangcono kunezinto ezindala. Lokhu kusho ukuthi izingxenye zihlala isikhathi eside futhi zidinga ukushintshwa okumbalwa. Amaqembu achitha isikhathi nemali encane ekunakekeleni.

Ingabe izingxenye ze-modular crusher kulula ukuzifaka?

Yebo, izingxenye ze-crusher ze-modular zisebenzisa amasistimu okushintsha ngokushesha. Izisebenzi zingawashintsha ngokushesha, ngokuvamile ngaphandle kwamathuluzi akhethekile. Lokhu kwenza ukufaka kuphephe futhi kube lula. Amaqembu achitha isikhathi esincane ekulungiseni futhi athole imishini esebenza futhi ngokushesha.

Ingabe izingxenye ze-crusher eco-friendly zibiza ngaphezulu?

Izingxenye ze-crusher ezinobungani bemvelo kwesinye isikhathi zibiza kancane ekuqaleni. Ngokuhamba kwesikhathi, bonga imali ngokuhlala isikhathi eside futhi banciphise ukumosha. Izinkampani eziningi zithola ukonga kwesikhathi eside kanye nezinzuzo zemvelo ezifanele ukutshalwa kwezimali.

Isikhathi sokuthumela: Jun-14-2025