A i-cone crusherithembele ezintweni ezisezingeni eliphezulu ukuphatha imisebenzi enzima, ikakhulukazi yayoizingxenye ze-cone crusher. Insimbi yeManganese, ikakhulukazi insimbi yaseHadfield, ibusa ukwakhiwa kwayo. Lesi sici sinikeza ubulukhuni obumangalisayo nokumelana nokugqokwa, ngaphezu kuka-12% we-manganese eqina ngesikhathi sokusetshenziswa. I-Cast iron ne-ceramic composites iphinde ithuthukise ukuqina kwe-cone crusher, iqinisekise ukuthi imelana nokucindezela okukhulu nezimo ezilimazayo.

Okuthathwayo Okubalulekile

- Insimbi ye-Manganeseyiyona nto eyinhloko kuma-cone crushers. Inamandla kakhulu futhi imelana nokuguga.

- Izinto eziqinile njengezingxube ze-ceramic zenza izingxenye zihlale isikhathi eside. Baphinde basize i-cone crushersebenza kangcono futhi udinga ukulungiswa okuncane.

- Ukukhetha izinto ezifanele kanye nokulungisa izilungiselelo kungasiza kakhulu. Yenza i-crusher isebenze kahle futhi ihlale isikhathi eside.

Izingxenye Ze-Cone Crusher Nezinto Zazo

I-Mantle ne-Concaves

Iingubo kanye concavesizingxenye ezibalulekile ze-cone crusher ezisebenzisana ngqo nezinto ezichotshozwayo. Lezi zingxenye ngokuvamile zenziwe ngensimbi ye-manganese, eqina ngaphansi kwengcindezi futhi imelane nokugqoka. Isiphuku sihlala phezu komgodi omkhulu, kuyilapho ama-concaves enza isitsha esimile nxazonke. Ndawonye, bakha igumbi lokuchotshozwa lapho amatshe acindezelwa futhi abhidlizwa khona.

Imibiko yokusebenza ibonisa ukuthi izilinganiso zokuguga zalezi zingxenye zincike ezintweni ezifana nezakhiwo zensimbi namamethrikhi okusebenza. Izindawo zokugqokwa okuphezulu kuma-concave liners ngokuvamile avela phakathi nemigqa engezansi, kuyilapho i-mantle ihlangabezana nokuguga okusatshalaliswe ngokulinganayo. Lokhu kugqamisa ukubaluleka kokukhetha izinto ezihlala isikhathi eside kanye nokuthuthukisa izilungiselelo ze-crusher ukuze kunwetshwe impilo yalezi zingxenye.

I-Main Shaft kanye ne-Eccentric Bushing

Iumphini omkhulufuthi i-eccentric bushing iwumgogodla wokusebenza kwe-cone crusher. I-shaft eyinhloko isekela i-mantle futhi idlulisa amandla okuchoboza, kuyilapho i-eccentric bushing ivumela ukuthi ingubo ihambe ngokunyakaza kwe-gyratory. Lezi zingxenye zivame ukwakhiwa kusuka kunsimbi enamandla amakhulu kanye nama-alloys ethusi ukuze kubekezelele ukucindezela okukhulu namandla okujikeleza ahilelekile.

- Izinkinga ezijwayelekile nge-eccentric bushing zifaka:

- Ukushisa ngokweqile kwamafutha okugcoba

- Amafayili ethusi kusikrini seyunithi ye-hydraulic

- Ukuvalwa okuphelele kwe-crusher

- Izinto ezibangela ukutubeka kwe-bushing:

- Ukugcoba okungalungile

- Olayini abangalungile noma ukucupha okungalungile

- Izinhlawulo ezeqile kokuphakelayo

Lapho kuvela ukutubeka, ochwepheshe kumelwe bahlonze imbangela, bahlanze futhi bapholishe i-shaft eyinhloko, futhi balinganise izingxenye ezilimele ukuze zishintshwe. Ukunakekelwa okufanele kuqinisekisa ukuthi lezi zingxenye ze-cone crusher zisebenza kahle futhi zihlala isikhathi eside.

Uhlaka kanye ne-Tramp Release Mechanism

Uhlaka luhlinzeka ngosekelo lwesakhiwo kuzo zonke izingxenye ze-cone crusher. Ngokuvamile kwenziwa ngensimbi ekhonjiwe noma insimbi ukuze kuqinisekiswe ukuzinza nokumelana nemithwalo esindayo. Ngakolunye uhlangothi, indlela yokukhishwa kwe-tramp, ivikela i-crusher emonakalweni obangelwa izinto ezingenakunyakaziswa njengemfucumfucu yensimbi.

Lo mshini usebenzisa amasistimu adonsa amanzi ukuze ukhulule ingcindezi futhi uvumele izinto ezingagayeki ukuthi zidlule ngokuphepha. Abakhiqizi bavame ukusebenzisa izinhlanganisela ze-ceramic kanye nensimbi yezinga eliphezulu kulezi zingxenye ukuqinisekisa ukuqina nokuthembeka. Uhlaka oluklanywe kahle kanye nendlela yokukhishwa kwe-tramp inomthelela ekusebenzeni kahle okuphelele nokuphepha kwe-crusher phakathi nokusebenza.

Kungani Kusetshenziswa Lezi Zizinto

Ukuqina Nokumelana Nokugqoka

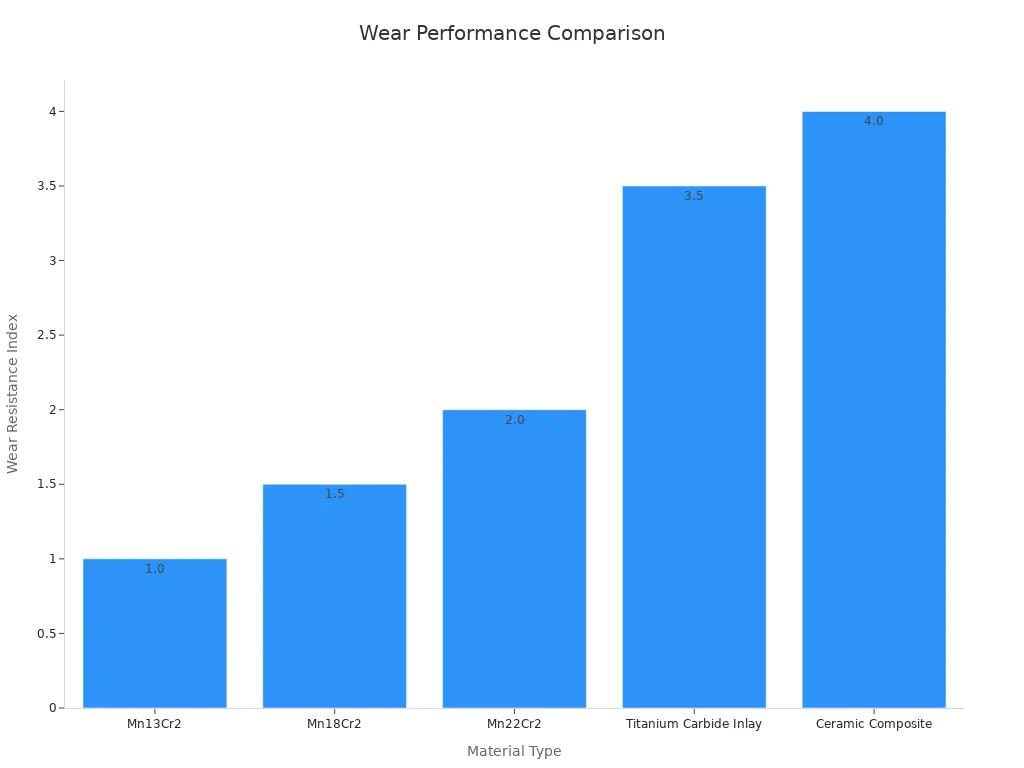

Izingxenye ze-cone crusher zibhekana nokuguga okudlulele kanye nokudabuka ngesikhathi sokusebenza. Ukulwa nalokhu, abakhiqizi basebenzisa izinto ezifanainsimbi ye-manganese nezinhlanganisela ze-ceramic. Insimbi ye-manganese, ikakhulukazi amabanga afana ne-Mn13Cr2 ne-Mn18Cr2, iyaqina ngaphansi kwengcindezi, iyenze ifaneleke ukuchoboza izinto ezilimazayo. Izinhlanganisela ze-Ceramic, ngakolunye uhlangothi, zinikeza ubulukhuni obuphezulu kakhulu futhi zigcina iphrofayili yazo ebukhali yokuchoboza ngisho nasezimweni ezinzima.

| Uhlobo Lwezinto | Ukuqina (HRC) | I-Wear Resistance Index | Ukumelana Nomthelela | Ubude bempilo obulindelwe (amahora) |

|---|---|---|---|---|

| Mn13Cr2 | 18-22 | 1.0 | ★★★★★ | 800-1200 |

| Mn18Cr2 | 22-25 | 1.5 | ★★★★☆ | 1200-1800 |

| I-Ceramic Composite | 60-65 | 4.0 | ★☆☆☆☆ | 3000-4000 |

Lezi zinsiza ziqinisekisa ukuthi i-crusher ingakwazi ukuphatha ukusetshenziswa isikhathi eside ngaphandle kokushintshwa njalo, ukunciphisa isikhathi sokuphumula kanye nezindleko zokuyilungisa.

Amandla Ezicelo Zokucindezela Okuphezulu

Ama-cone crushers asebenza ngaphansi kwengcindezi enkulu, ikakhulukazi lapho ecubungula izinto eziqinile njenge-quartz noma i-granite.Insimbi enamandla amakhulu kanye ne-titanium carbideama-inlay avame ukusetshenziselwa izingxenye ezifana ne-shaft eyinhloko nesiphuku. Ama-inlay e-Titanium carbide, isibonelo, athuthukisa ukumelana nokugqokwa izikhathi ezingu-1.8 futhi abe nomthelela izikhathi ezingu-8.8 uma kuqhathaniswa nezinto ezivamile. Lawa mandla aqinisekisa ukuthi i-crusher ingakwazi ukuphatha izinhlelo zokusebenza ezinomfutho ophezulu ngaphandle kokubeka engcupheni ukusebenza.

Ukuzivumelanisa Nezidingo Ezihlukahlukene Zokuchoboza

Imisebenzi ehlukene yokuchoboza idinga izinto ezikwazi ukuzivumelanisa nezimo ezihlukahlukene. Isibonelo, i-Mn18Cr2 ihamba phambili ekuphatheni izinto ezingajwayelekile ezinokungcola ngenxa yokumelana nomthelela omuhle kakhulu. Izinhlanganisela ze-Ceramic zifaneleka kangcono ukuchotshozwa kwezinto eziqinile kakhulu. Ukuhlolwa kokusebenza kusetshenziswa ukulingiswa kwezinombolo, okufana nendlela ye-elementi ehlukene (DEM), kubonise ukuthi ukulungiselela amapharamitha afana nesivinini sokujikeleza nama-engeli ekhoni kungathuthukisa ngokwengeziwe ukuguquguquka. I-Y51 cone crusher, isibonelo, izuze ukukhiqiza okuphezulu nge-engeli yangaphambili engu-1.5° kanye nesivinini sokujikeleza esingu-450 rad/min.

Ngokukhetha izinto ezisetshenziswayo ezifanele kanye nokucushwa, izingxenye ze-cone crusher zingahlangabezana nezidingo ezihlukene zokusebenza ngenkathi kugcinwa ukusebenza kahle.

Indlela Izinto Ezisebenza Ngayo Ezithinta Ngayo Ukusebenza Kwe-Crusher

Ukusebenza Okuthuthukisiwe Nokuphila Isikhathi Eside

Izinto ezisetshenziswa ezingxenyeni ze-cone crusher zidlala indima enkulu ekuthuthukiseni ukusebenza kahle nokwelula isikhathi sokuphila somshini. Izinto zekhwalithi ephezulu njengensimbi ye-manganese nezinhlanganisela ze-ceramic ziqinisekisa ukuthi izingxenye zingakwazi ukuphatha umsebenzi osindayo ngaphandle kokuguga ngokushesha. Isibonelo, izinto ezingagugi zingahlala izikhathi ezimbili kuya kwezine kunezomdabu, zinciphise isidingo sokushintshwa njalo.

| Ubufakazi | Incazelo |

|---|---|

| Izinto ezisezingeni eliphezulu | Isetshenziselwa ukukhiqiza izingxenye eziqinile. |

| Izinto ezimelana nokugqokwa | Thuthukisa ukuqina, okuhlala izikhathi ezi-2 kuye kwezi-4 ubude. |

Izinto ezihlala isikhathi eside zinciphisa nokulahlekelwa amandla ngesikhathi sokusebenza. Ucwaningo luye lwabonisa ukuthi ama-crushers akhiwe ngezinto eziqinile ahlangabezana nokuguga okuncane, okusho ukuthi agcina ukusebenza kwawo ngokuhamba kwesikhathi. Lokhu kuqina kuqinisekisa ukuthi i-crusher isebenza kahle, ngisho nangaphansi kwezimo ezinzima.

| Ubufakazi | Incazelo |

|---|---|

| Ama-cone crushers asezingeni eliphezulu | Yenzelwe ukuthi ihlale ngezinto ezimelana nemihuzuko. |

| Izinto eziqinile | Kuholela ekugugeni kancane, ukuthuthukisa ukusebenza kahle. |

Ukwehliswa Kwesondlo Nesikhathi Sokuphumula

Ukunakekela njalo kungaphazamisa ukusebenza futhi kwenyuse izindleko. Ngokusebenzisa izinto eziqinile nezingagugi, abakhiqizi banciphisa isidingo sokulungiswa. Isibonelo, insimbi ye-manganese iyaqina ngaphansi kwengcindezi, iyenze ibe yinhle ezingxenyeni ezinjengama-mantle nama-concave. Lesi sakhiwo sinciphisa izinga lokuguga, okuvumela i-crusher ukuthi isebenze isikhathi eside ngaphandle kokuphazamiseka.

Ucwaningo olukhulu ngo-1982 lwakala amandla okuphuka kanye nezici zokuphuka kwensimbi yezingqimba zokukhiqiza. Imiphumela yabonisa ukuthi ukusebenzisa izinto ezisezingeni eliphezulu kunciphisa kakhulu ukuphazamiseka kokusebenza. Ama-specimens avela ocwaningweni ahlolwe ngezinqubo ze-pendulum zamandla aphezulu, eziqinisekisa ikhono lezinto zokumelana nezimo ezimbi kakhulu.

Ukwengeza, ukukhethwa kwempahla kunomthelela ekutheni i-crusher iwaphatha kahle kanjani amazinga ahlukene omgodi. Ama-crusher asebenza anemigodi egcwele nezinto zetshe eliqinile abonisa ukusebenza kahle kokukhiqiza okuthuthukisiwe. Ngakolunye uhlangothi, ukusebenza kwe-low-cavity nge-soft rock material ngokuvamile kuholela ekusebenzeni okuguquguqukayo, okudinga ukulungiswa okuphindaphindiwe.

| I-Cavity Level | Uhlobo Lwezinto | Imiphumela Ebhekiwe |

|---|---|---|

| Umgodi ophansi | Itshe elithambile | Ukwenyuka kokusetshenziswa kwamandla. |

| Umgodi ophezulu | Itshe eliqinile | Izakhiwo zokunciphisa ezithuthukisiwe. |

Ukunemba Okuthuthukisiwe Kokuchoboza

Izinto ezifanele futhi zithuthukisa ukunemba kwenqubo yokuchotshozwa. Isibonelo, izinhlanganisela ze-ceramic zigcina iphrofayili yazo ebukhali, ngisho nangemva kokusetshenziswa isikhathi eside. Lokhu kuvumelana kuqinisekisa ukuthi i-crusher ikhiqiza izinto ezilingana neyunifomu, okubalulekile ezimbonini ezifana nezokwakha nezimayini.

Amasistimu okulawula ukunciphisa usayizi ngokuzenzakalelayo athuthukisa ukunemba. Ama-crusher ahlomeke ngalawa masistimu athola ukuhluka okungaphansi ngo-38-46% kumamethrikhi okusebenza. Ukukhiqizwa okungaguquki futhi kukhulisa ukusebenza kwesekethe okumaphakathi ngo-12-16%, okwenza i-crusher ithembeke kakhulu.

| Okutholakele Okubalulekile | Umthelela Ekusebenzeni |

|---|---|

| Ukulawula ukwehlisa usayizi okuzenzakalelayo | 38-46% ukuhluka okuphansi kwamamethrikhi okusebenza. |

| Ukungaguquguquki ekukhiqizeni | Ukwanda kwe-12-16% ekusebenzeni kwesifunda. |

Ngokuhlanganisa izinto ezithuthukisiwe nobunjiniyela obunembile, izingxenye ze-cone crusher ziletha ukusebenza okukhethekile. Le nhlanganisela ayigcini nje ngokuthuthukisa ukunemba kokuchotshozwa kodwa futhi iqinisekisa ukuthi umshini uhlangabezana nezidingo zezinhlelo zokusebenza ezihlukahlukene.

Izinto ezisetshenziswa kuma-cone crushers zibalulekile ukuze ziqine futhi zisebenze kahle. Insimbi ye-Manganese, insimbi ye-carbon, izinhlanganisela ze-ceramic, nensimbi ekhonjiwe iqinisekisa ukuthi le mishini ingakwazi ukuphatha izinhlelo zokusebenza ezinzima futhi imelane nokuguga ngokuhamba kwesikhathi.

- Ama-cone crushers athuthukisa ukusebenza kahle kwamandla ngo-10-30%, ehlisa izindleko zokusebenza.

- Ama-Crushers agcina ukukhiqiza okungaguquguquki ngosayizi ofanayo wezinto, ngisho nokuhluka kwedizayini yegumbi.

- Ochwepheshe bemboni bagcizelela ukuthuthukiswa kwezingxenye zokugqokwa nokulungiswa kwegumbi ukuze usebenze kangcono nokuphila isikhathi eside.

Ukukhethwa kwezinto ezifanele akugcini nje ngokuthuthukisa ukwethembeka kwe-crusher kodwa futhi kusekela isidingo semboni yezimayini sokucubungula amathani amatshe angaphezu kwesigidi esingu-1.3 ngonyaka. Ngokulinganisa idizayini nokuguquguquka kokusebenza, ama-cone crushers aletha imiphumela engashintshi kuzo zonke izinhlelo zokusebenza ezahlukahlukene.

FAQ

Yiziphi izingxenye ezibaluleke kakhulu ze-cone crusher?

Isigqoko, ama-concave, i-main shaft, i-eccentric bushing, kanye nohlaka yizici ezibalulekile. Ingxenye ngayinye idlala indima ebalulekile enqubweni yokuchotshozwa.

Izinto zokwakha zikuthinta kanjani ukusebenza kwezingxenye ze-cone crusher?

Izinto ezisezingeni eliphezulu zithuthukisa ukuqina,nciphisa ukuguga, futhi kuthuthukise ukusebenza kahle. Baqinisekisa ukuthi i-crusher isebenza kahle, ngisho nangaphansi kwezimo ezinzima.

Kungani insimbi ye-manganese ivame ukusetshenziswa ezingxenyeni ze-cone crusher?

Insimbi ye-Manganese iyaqina ngaphansi kwengcindezi, iyenze ibe ilungele ukuchoboza izinto eziabrasive. Ukuqina kwayo kwandisa isikhathi sokuphila sezingxenye ezibalulekile njengengubo nama-concave.

Isikhathi sokuthumela: Jun-03-2025