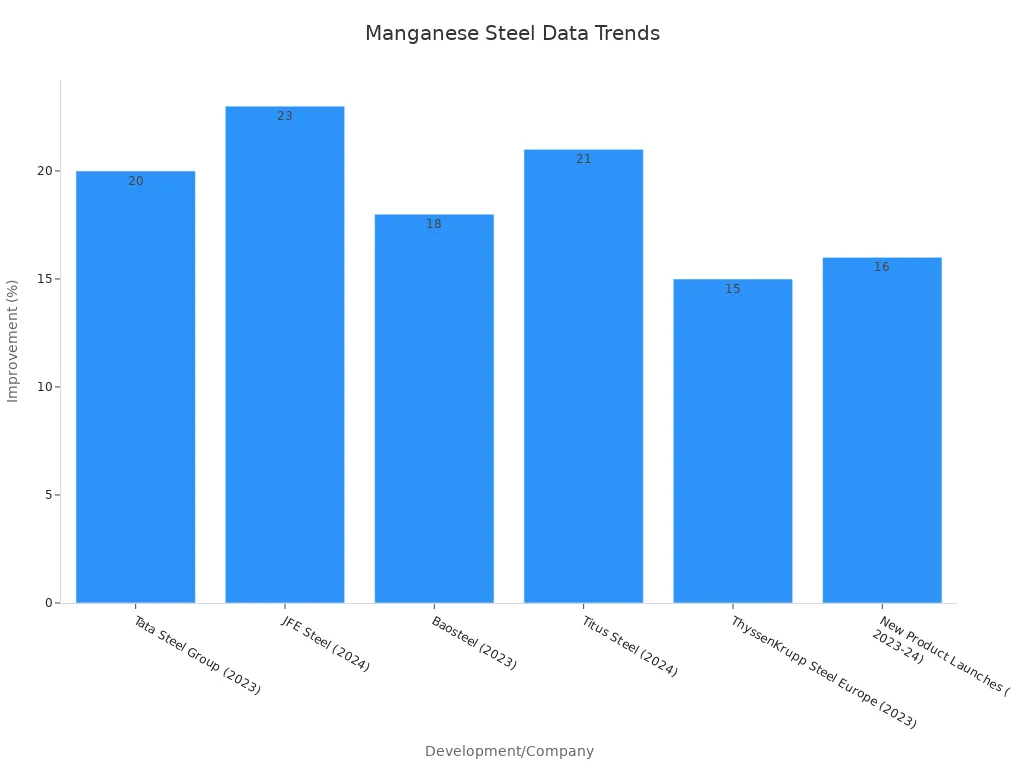

Insimbi yeManganeseiyinto ebalulekile embonini esindayo, eyaziwa ngamandla ayo angavamile, ukuqina, nokumelana nokugqoka okungamataniswa nezinto ezimbalwa.High Mn Steel, okuhlanganisa I-Manganese Steel Plates kanye Ne-Manganese Steel Castings, iqinisekisa ukuthi imishini isebenza kahle ngisho nangaphansi kwezimo ezimbi kakhulu. Izinkampani zithola ukusebenza okuthuthukisiwe okufika ku-23% nempilo yesevisi eyandisiwe, njengoba kuboniswe ngezansi:

Okuthathwayo Okubalulekile

- Insimbi ye-Manganeseinamandla ngokwedlulele futhi iqinile ngenxa yokuqukethwe kwayo okuphezulu kwe-manganese, okuyisiza ukuthi ibe nzima uma ishaywa noma icindezelwa.

- Le nsimbi imelana nokuguga, umthelela, nokugqwala kangcono kunezinye izinsimbi eziningi, okuyenza ilungele imishini yemboni esindayo ebhekana nezimo ezimbi.

- Izimboni ezinjengezimayini, ezokwakha, nezitimela zithembele kuzoinsimbi ye-manganeseukugcina okokusebenza kuphephile, kuqinile, futhi kusebenza isikhathi eside ngokulungiswa okuncane.

Insimbi yeManganese: Ukwakheka nezici Eziyingqayizivele

Yini Ehlukanisa Insimbi YeManganese

Insimbi yeManganese igqama ngenxa yokuhlanganiswa kwayo okukhethekile kwezinto. Izinhlobo eziningi ziqukethe cishe u-10-14% we-manganese kanye no-1-1.4% wekhabhoni, kanti okunye kuyinsimbi. Ezinye izinsimbi ezine-manganese ephezulu ezisetshenziswa ezimayini noma ezitimeleni zingaba nama-manganese afika ku-30%. Lokhu okuqukethwe okuphezulu kwe-manganese kunikeza insimbi amandla ayo adumile nokuqina. Ososayensi bathole ukuthi i-manganese iyashintsha indlela insimbi eyakha futhi iguquke ngayo. Isiza insimbi ukuthi ihlale iqinile futhi iqinile, ngisho noma ibhekene namahithi aqinile noma imithwalo esindayo.

Ucwaningo lwesayensi yezinto ezibonakalayo lubonisa ukuthi insimbi ye-manganese inesakhiwo esincane esiyingqayizivele. Lapho insimbi igoba noma inwetshwa, izinguquko ezincane zenzeka ngaphakathi. Lezi zinguquko, ezibizwa nge-TWIP kanye nemiphumela ye-TRIP, zisiza insimbi ukuthi ibe namandla nakakhulu ngaphandle kokuphuka. Insimbi ingaphinde igcine amandla ayo emazingeni okushisa asuka ku -40 kuya ku-200 °C.

Ithebula elingezansi libonisa ukwakheka okujwayelekile kwensimbi ye-manganese uma kuqhathaniswa nezinye izinsimbi:

| I-Alloying Element | Ukwakheka Kwephesenti Elijwayelekile (wt%) | Ibanga noma Amanothi |

|---|---|---|

| Ikhabhoni (C) | 0.391 | Okujwayelekileipuleti lensimbi ye-manganese |

| I-Manganese (Mn) | 18.43 | Ipuleti lensimbi le-manganese elijwayelekile |

| I-Chromium (Cr) | 1.522 | Ipuleti lensimbi le-manganese elijwayelekile |

| I-Manganese (Mn) | 15-30 | Izinsimbi eziphezulu ze-manganese |

| Ikhabhoni (C) | 0.6 - 1.0 | Izinsimbi eziphezulu ze-manganese |

| I-Manganese (Mn) | 0.3 – 2.0 | Ezinye izinsimbi ze-alloy |

| I-Manganese (Mn) | >11 | Izinsimbi ze-Austenitic zokumelana nokugqoka okuphezulu |

Ukuqhathanisa Nezinye Izinsimbi

Insimbi yeManganese isebenza kangcono kunezinye izinsimbi eziningi emisebenzini enzima. Inamandla aphezulu okudonsa futhi ingakwazi ukuphatha umthelela owengeziwe. Insimbi ibuye iba lukhuni uma ishaywa noma icindezelwa, okuyisiza ukuthi ihlale isikhathi eside ezindaweni ezinokhahlo njengezimayini noma ujantshi.

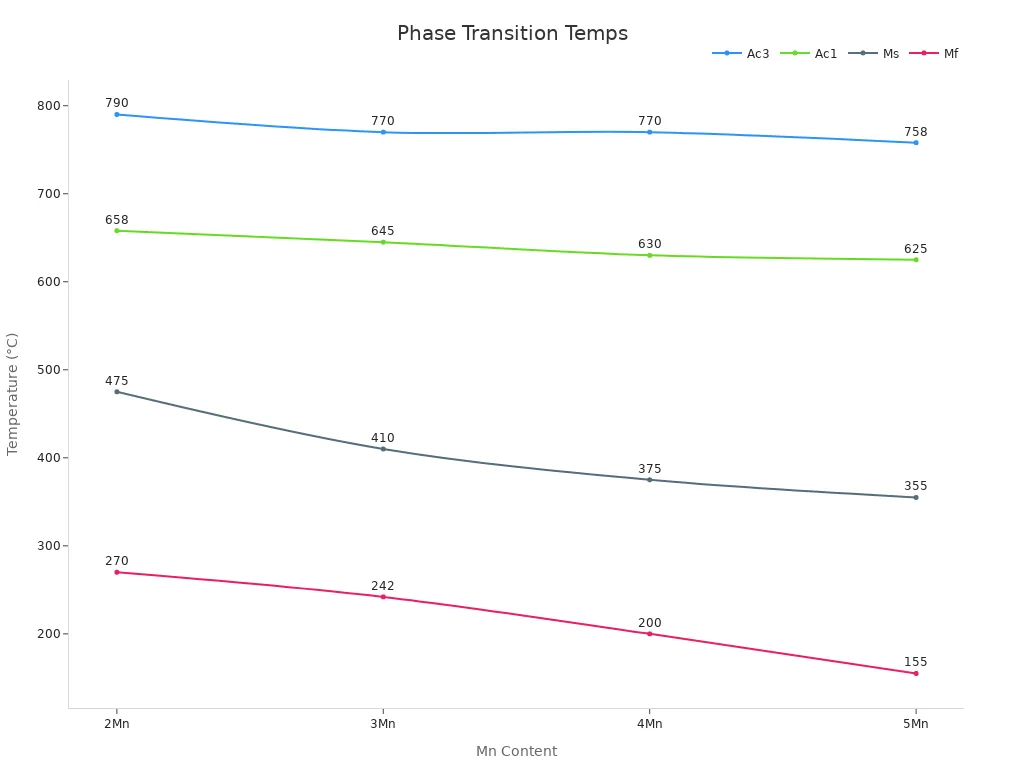

Ishadi elingezansi libonisa ukuthi okuqukethwe kwe-manganese kuwathinta kanjani amandla ensimbi nezinguquko zesigaba:

Uma iqhathaniswa nensimbi engagqwali, insimbi ye-manganese inokumelana nomthelela ongcono nokumelana nokugqoka. Insimbi engagqwali imelana nokugqwala kangcono, kodwa insimbi ye-manganese iyinketho ephezulu yezindawo lapho okokusebenza kubhekene nokushaywa nokuklwebheka okuningi.

Ithiphu:Insimbi ye-Manganese ilukhuni ukuyifaka umshiningoba kuba nzima uma usebenza kukho. Izisebenzi zivame ukusebenzisa amathuluzi akhethekile ukuyisika noma ukuyilolonga.

Izakhiwo Ezibalulekile Zensimbi YeManganese Embonini

Umthelela kanye Nokumelana Nokuhushulwa

Insimbi yeManganese igqama ngekhono layo lokuphatha amahithi aqinile kanye nokuphathwa kabi. Embonini enzima, imishini ivame ukubhekana namatshe, amatshe, nezinye izinto ezinzima. Uma lezi zinto zishaya noma ziklwebheka insimbi, izinsimbi eziningi ziwohloka ngokushesha. Insimbi yeManganese, nokho, iba namandla ngomthelela ngamunye. Lokhu kwenzeka ngenxa yokuthi ukwakheka kwayo kushintsha ngaphansi kwengcindezi, okwenza ubuso bube nzima ngenkathi igcina ingaphakathi liqinile.

Abacwaningi bahlole insimbi ye-manganese ngokuyishaya ngomshini we-tungsten-carbide elebhu. Bengeze izinhlayiya zensimbi ezicijile ukuze benze ukuhlolwa kube nzima nakakhulu. Insimbi ibambe kahle, ikhombisa ukuguga okuncane ngisho nangemva kwemithelela ephindaphindiwe. Kokunye ukuhlola, kwasetshenziswa onjiniyelaama-crushers emihlathiniukugaya amatshe. Imihlathi yensimbi ye-manganese yalahlekelwa isisindo esincane futhi yahlala ibushelelezi kunezinye izinsimbi. Ososayensi bathola izinhlamvu ezincane namaphethini akhethekile ngaphakathi kwensimbi ngemva kwalokhu kuhlola. Lezi zinguquko zisiza insimbi ukuthi imelane nokusika nokuboleka.

Uthi bewazi? Insimbi yeManganese iba lukhuni uma isebenza kakhulu. Lokhu "ukuqina komsebenzi" kuyenza ifaneleke kakhulu ukumba izimayini, ukumba izinkwali, kanye nemishini yokuchoboza.

Onjiniyela baphinde basebenzisa insimbi ye-manganese ezingxenyeni ezishelelayo noma ezihlikihlwayo, njengamathrekhi kaloliwe nemihlahlandlela yokusika amalahle. Lezi zembatho zihlala isikhathi eside futhi zimelana nokulimala kwemithwalo esindayo nokunyakaza okuqhubekayo. Imfihlo ilele ekuxubeni kwezakhi kanye nendlela insimbi eshintsha ngayo lapho icindezelekile.

Ukuqina Nokuqina

Ukuqina kusho ukuthi into ethile ingahlala isikhathi eside, ngisho noma isetshenziswa nsuku zonke. Ukuqina kusho ukuthi kungathatha ukushaya ngaphandle kokuphuka. Insimbi yeManganese ithola amaphuzu aphezulu kuzo zombili izindawo. Ucwaningo lwelebhu lubonisa ukuthi insimbi ye-manganese emaphakathi inganwebeka ngaphezu kuka-30% ngaphambi kokuphuka futhi inamandla aqinile angaphezu kuka-1,000 MPa. Lokhu kusho ukuthi ingagoba futhi igobe ngaphandle kokugqashuka.

Lapho imishini isebenza amahora noma izinsuku, izingxenye zayo zibhekana nokucindezeleka okuphindaphindiwe. Insimbi yeManganese ikuphatha kahle lokhu. Ukuhlola kubonisa ukuthi imelana nemifantu futhi ibambezela umonakalo, ngisho noma ilayishwa kaningi. Ososayensi basebenzisa amamodeli akhethekile ukubikezela ukuthi insimbi izoziphatha kanjani ngokuhamba kwesikhathi. Lawa mamodeli abonisa ukuthi insimbi ye-manganese ivumelana nengcindezi, isakaza umonakalo, futhi iqhubeka nokusebenza isikhathi eside kunezinye izinsimbi eziningi.

- Ukuhlola ukuqina okuqhathaniswayo kugqamisa ukuqina kwensimbi ye-manganese:

- Ukuhlolwa kokuqina namandla okuthinta kubonisa ukuthi izinsimbi ze-vanadium manganese eziphezulu zishaya insimbi ye-Hadfield evamile.

- Ukuhlolwa kwe-pin-on-disk ne-ball mill kufakazela ukuthi ukumelana nensimbi ye-manganese kugqoka kangcono kunamanye ama-alloy anamandla aphezulu.

- Ukuhlola okuqinile kuveza ukuthi izinsimbi ze-manganese ezihlanganisiwe zihlala ziqinile futhi zivumelana nezimo, ngisho nangesivinini esihlukile sokunwebeka.

- Yengeza ama-elementi afana ne-chromium, i-tungsten, ne-molybdenum yenza insimbi iqine nakakhulu futhi imelane nokugqokwa.

Qaphela: Isakhiwo esikhethekile sensimbi ye-manganese siyisiza ukuthi imunce amandla futhi ibambezele ukuqhekeka. Lokhu kugcina imishini isebenza ngokuphepha futhi kunciphisa isidingo sokuyilungisa.

Ukumelana Nokugqwala

Ukugqwala kwenzeka lapho insimbi ihlangana namanzi, umoya, noma amakhemikhali futhi iqala ukuwohloka. Ezindaweni ezinjengezimayini noma eduze nolwandle, ukugqwala kungonakalisa imishini ngokushesha. Insimbi yeManganese inikeza ukuvikeleka okuhle, ikakhulukazi uma iphathwa ngezinto ezengeziwe ezifana ne-molybdenum noma i-chromium. Lezi zakhi zisiza ukwakha ungqimba oluncane, oluzinzile endaweni yensimbi. Lolu ngqimba luvimba amanzi namakhemikhali, lwehlise ukugqwala nokunye ukulimala.

Ukuhlolwa kwelebhu kubonisa ukuthi insimbi ye-manganese ene-molybdenum nokwelashwa okukhethekile kokushisa imelana nokugqwala kangcono kakhulu. Ososayensi basebenzisa izibonakhulu ukuze babone lezi zingqimba ezivikelayo. Baphinde benze izivivinyo zikagesi ukukala ukuthi insimbi igqwala ngokushesha kangakanani. Imiphumela ibonisa ukuthi insimbi ye-manganese ephathwayo ihlala isikhathi eside ezindaweni ezinzima.

Kodwa-ke, ezindaweni ezine-acidic kakhulu, insimbi ye-manganese isengabhekana nezinkinga ezifana nokubhoboza noma ukuqhekeka. Kungakho onjiniyela bevame ukungeza izakhi eziningi noma basebenzise izindlela zokwelapha ezikhethekile ukuze baqinise ukumelana kwayo.

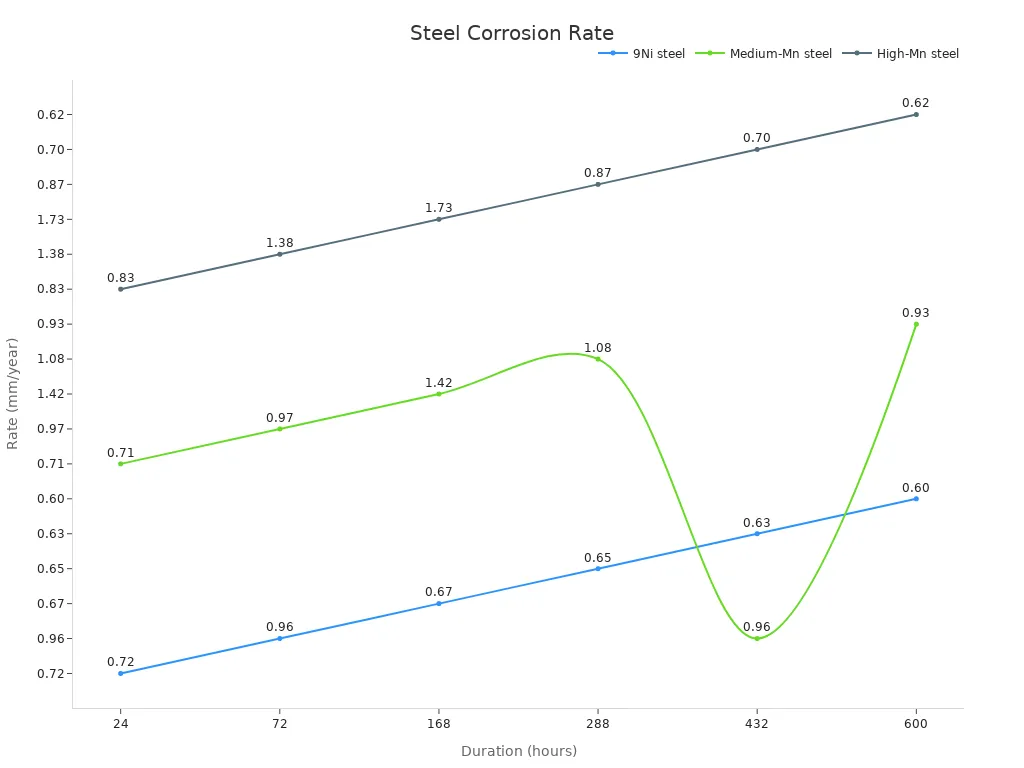

Ithebula elingezansi liqhathanisa ukuthi izinsimbi ezihlukene zigqwala ngokushesha kangakanani endaweni yasolwandle:

| Isikhathi Sokugqwala (amahora) | 24 | 72 | 168 | 288 | 432 | 600 |

|---|---|---|---|---|---|---|

| 9Insimbi | 0.72 | 0.96 | 0.67 | 0.65 | 0.63 | 0.60 |

| Insimbi ye-Medium-Mn | 0.71 | 0.97 | 1.42 | 1.08 | 0.96 | 0.93 |

| High-Mn steel | 0.83 | 1.38 | 1.73 | 0.87 | 0.70 | 0.62 |

Izinga lokugqwala kwensimbi ye-Manganese liyehla ngokuhamba kwesikhathi njengefilimu evikelayo. Lokhu kuyisiza ukuthi ihlale isikhathi eside, ngisho nasezindaweni ezimanzi noma ezinosawoti. Izinsimbi ze-manganese ezine-Chromium nazo zehlisa ukugqwala futhi zehlise ubungozi bokuqhekeka okuvela ku-hydrogen.

Ithiphu: Ukuze uthole imiphumela engcono kakhulu ezindaweni ezinokhahlo, onjiniyela bakhetha insimbi ye-manganese ene-chromium eyengeziwe noma i-molybdenum futhi basebenzise ukwelashwa okukhethekile kokushisa.

Insimbi yeManganese ku-Real-World Industrial Applications

Izinsiza Zezimayini Nezinkwali

Izimayini kanye nokumba inkwali kubeka imishini ezimeni ezinzima. Izisebenzi zisebenzisa imishini echoboza, igaye futhi inyakaze amatshe asindayo nsuku zonke. Insimbi yeManganese isiza le mishini ukuthi ihlale isikhathi eside. Ukuhlolwa kwezimboni kukhombisa lokhoinsimbi ye-manganese ephakathi, njenge-Mn8/SS400, ilahlekelwa isisindo esincane kakhulu ngenxa yokugqoka kunezinye izinsimbi. Ngaphezu kwamahora angu-300, le nsimbi yehle cishe ngo-69% isisindo esingaphansi kunezinsimbi zendabuko ze-martensitic. Noma ingeyona enzima kakhulu, imunca amandla amaningi futhi imelane nemithelela engcono. Lokhu kusho ukuthi izinkampani zezimayini zingasebenzisa imishini yazo isikhathi eside futhi zichithe imali encane ekuyilungiseni.

Ithiphu: Ikhono lensimbi ye-Manganese lokuba namandla uma ishaywa liyenza ipheleleama-crushers emihlathini, ama-hopper, namalayini ezimayini.

Imishini Yokwakha Nengqalasizinda

Izindawo zokwakha zidinga imishini eqinile nephephile. Insimbi ye-Manganese inikeza kokubili. Isiza imishini ukuphatha imithwalo esindayo kanye nokuphathwa kabi. Ithebula elingezansi libonisa ukuthi izinhlobo ezahlukene zensimbi ye-manganese zithuthukisa kanjani ukuphepha nokuqina ekwakhiweni:

| Uhlobo Lwensimbi | Okuqukethwe kweManganese (%) | Izinzuzo Eziyinhloko |

|---|---|---|

| Insimbi yeHadfield | 12-14 | Ukumelana nokugqoka okuphezulu, ukuqina komsebenzi |

| Insimbi yeCarbon-Manganese | Iyahlukahluka | Iqinile, iqinile, kulula ukuyishisela |

Abakhi basebenzisa insimbi ye-carbon manganese ephansi ukwenza imishayo namakholomu. Izinhlobo zekhabhoni ephezulu zisebenza kahle kakhulu emishinini enzima. Lezi zinsimbi zigcina umumo namandla azo, ngisho nalapho zisetshenziswa nsuku zonke. Izinkampani zokwakha zikhetha insimbi ye-manganese ngoba ihlala isikhathi eside futhi igcina abasebenzi bephephile.

Imboni Yezokuthutha kanye Nezitimela

Izitimela nezitimela zidinga izinto ezikwazi ukubhekana nokucindezeleka okuqhubekayo. Izinsimbi ze-high-manganese cast, njengensimbi ye-Hadfield, zisebenza kahle kumathrekhi wesitimela nezingxenye. Lezi zinsimbi ziba nzima njengoba izitimela zidlula phezu kwazo. Abacwaningi bathole ukuthi ukwengeza i-chromium kwenza insimbi ibe namandla futhi izinze. I-microstructure yensimbi iyashintsha ngesikhathi sokusetshenziswa, esiza ukuthi imelane nokuguga nokulimala. Izinkampani zikaloliwe zethemba insimbi ye-manganese ngokuphepha kwayo nempilo ende. Amamodeli wekhompyutha akhombisa ukuthi imelana nemithwalo ephindaphindwayo evela ezitimeleni ezisheshayo, igcina amathrekhi ephephile futhi eqinile.

- Izinsimbi eziphezulu ze-manganese ziyaziqinisa ngaphansi kwemithwalo esindayo.

- I-Chromium ikhuphula ubulukhuni nokuzinza.

- Izinguquko ze-Microstructure zisiza ukumelana nokuguga nokukhasa.

Qaphela: Ojantshi besitimela bathembele ensimbi ye-manganese ukunciphisa ukulungiswa nokugcina izitimela zisebenza ngokuphepha.

I-Manganese Steel igqama embonini enzima. Izinkampani zibona izinzuzo zangempela:

- Amandla omthelela aphezulu kanye nokumelana nokugqokwa kugcina okokusebenza kusebenza isikhathi eside.

- Izindlela zokwenza imishini ehlakaniphile, njengokushisisa okungeniswayo namathuluzi e-carbide, zithuthukisa ukukhiqiza.

- Ukuqina kwayo namandla okuqinisa umsebenzi kusiza ukumunca imithelela esindayo futhi imelane nokuguga.

FAQ

Yini eyenza insimbi ye-manganese ibe lukhuni kangaka?

Insimbi yeManganese iba namandla uma ishaywa. Yakhoingxube ekhethekile yezakhiisiza ukuthi imelane nezifaca nokuqhekeka, ngisho nasemsebenzini onzima.

Ungakwazi yini ukushisela noma ukusika insimbi ye-manganese kalula?

Ukushisela nokusika insimbi ye-manganese kungaba luqili. Izisebenzi zisebenzisa amathuluzi nezindlela ezikhethekile ngoba insimbi iyaqina lapho besebenza kuyo.

Abantu basebenzisa kuphi insimbi ye-manganese kakhulu?

Abantu babona insimbi ye-manganese ezimayini, ezitimeleni nasekwakhiweni. Isebenza kahle kakhulu ezindaweni lapho imishini ibhekana nomthelela omkhulu nokuguga.

Isikhathi sokuthumela: Jun-19-2025